Temperature-resistant salt-resistant HPAM/Cr<3+>/phenolic aldehyde compound crosslinked weak gel profile adjusting and water plugging agent and preparation method thereof

A profile control water shutoff agent, heat-resistant and salt-resistant technology, applied in the direction of chemical instruments and methods, drilling compositions, etc. Good salt performance, high gel strength, and improved heat and salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

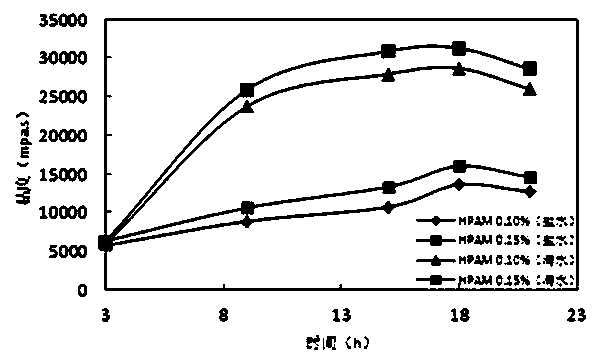

Embodiment 1

[0046] First weigh each raw material according to the following amounts:

[0047] Partially hydrolyzed polyacrylamide (HPAM): 0.10%

[0048] Metal crosslinking agent: 0.001%

[0049]Organic crosslinking agent: 0.03%

[0050] Ammonium chloride: 0.2%

[0051] The remainder is water;

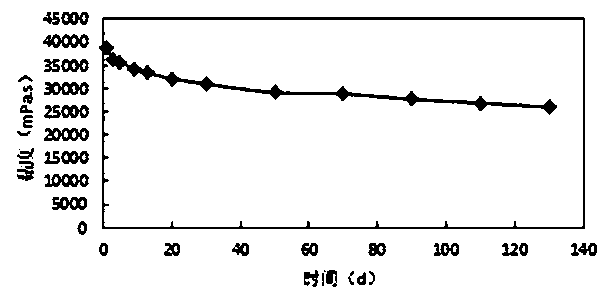

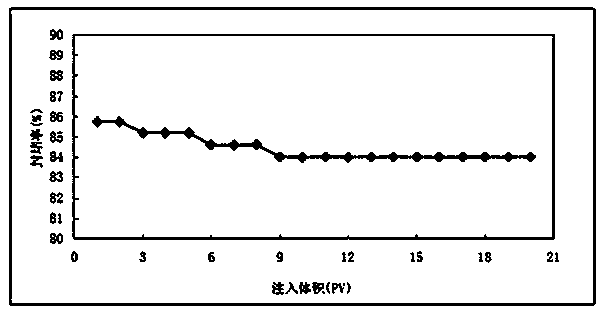

[0052] Add ammonium chloride into water and stir to make it fully dissolved; then add partially hydrolyzed polyacrylamide and stir with a stirrer for 30 minutes, then age at room temperature for 12 hours. After 12 hours, add the metal cross-linking agent and stir evenly, then place it at room temperature for 6 hours to obtain a weak gel complexed by metal ions; add the organic cross-linking agent to the synthesized weak gel, stir it evenly and place it Keep the temperature in a water bath at 75°C for 24 hours to allow polymerization to occur, and a reddish-brown viscous colloid is obtained, which is the heat-resistant and salt-resistant HPAM / Cr 3+ / Finished product of phenolic composite cross...

Embodiment 2

[0054] First weigh each raw material according to the following amounts:

[0055] Partially hydrolyzed polyacrylamide (HPAM): 0.10%

[0056] Metal crosslinking agent: 0.001%

[0057] Organic crosslinking agent: 0.04%

[0059] The remainder is water;

[0060] Ammonium oxalate was added to water and stirred to fully dissolve it; then partially hydrolyzed polyacrylamide was added and stirred with a stirrer for 30 minutes, then aged at room temperature for 12 hours. After 12 hours, add the metal cross-linking agent and stir evenly, then place it at room temperature for 6 hours to obtain a weak gel complexed by metal ions; add the organic cross-linking agent to the synthesized weak gel, stir it evenly and place it Keep the temperature in a water bath at 75°C for 24 hours to allow polymerization to occur, and a reddish-brown viscous colloid is obtained, which is the heat-resistant and salt-resistant HPAM / Cr 3+ / Finished product of phenolic compo...

Embodiment 3

[0062] First weigh each raw material according to the following amounts:

[0063] Partially hydrolyzed polyacrylamide (HPAM): 0.15%

[0064] Metal crosslinking agent: 0.002%

[0065] Organic crosslinking agent: 0.02%

[0066] Glacial acetic acid: 0.1%

[0067] The remainder is water;

[0068] Add glacial acetic acid into water, and stir; to fully dissolve it; then add partially hydrolyzed polyacrylamide, and stir with a stirrer for 30 minutes, then age at room temperature for 12 hours. After 12 hours, add the metal cross-linking agent and stir evenly, then place it at room temperature for 6 hours to obtain a weak gel complexed by metal ions; add the organic cross-linking agent to the synthesized weak gel, stir it evenly and place it Keep the temperature in a water bath at 75°C for 24 hours to allow polymerization to occur, and a reddish-brown viscous colloid is obtained, which is the heat-resistant and salt-resistant HPAM / Cr 3+ / Finished product of phenolic composite cro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com