Preparation method of titanium dioxide self-cleaning film

A technology of titanium dioxide and thin film, which is applied in the field of preparation of super-hydrophilic TiO2 thin film, which can solve the problems of expensive equipment, low coating efficiency and high operating cost, and achieve the effect of uniform distribution of film surface, excellent hydrophilicity and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

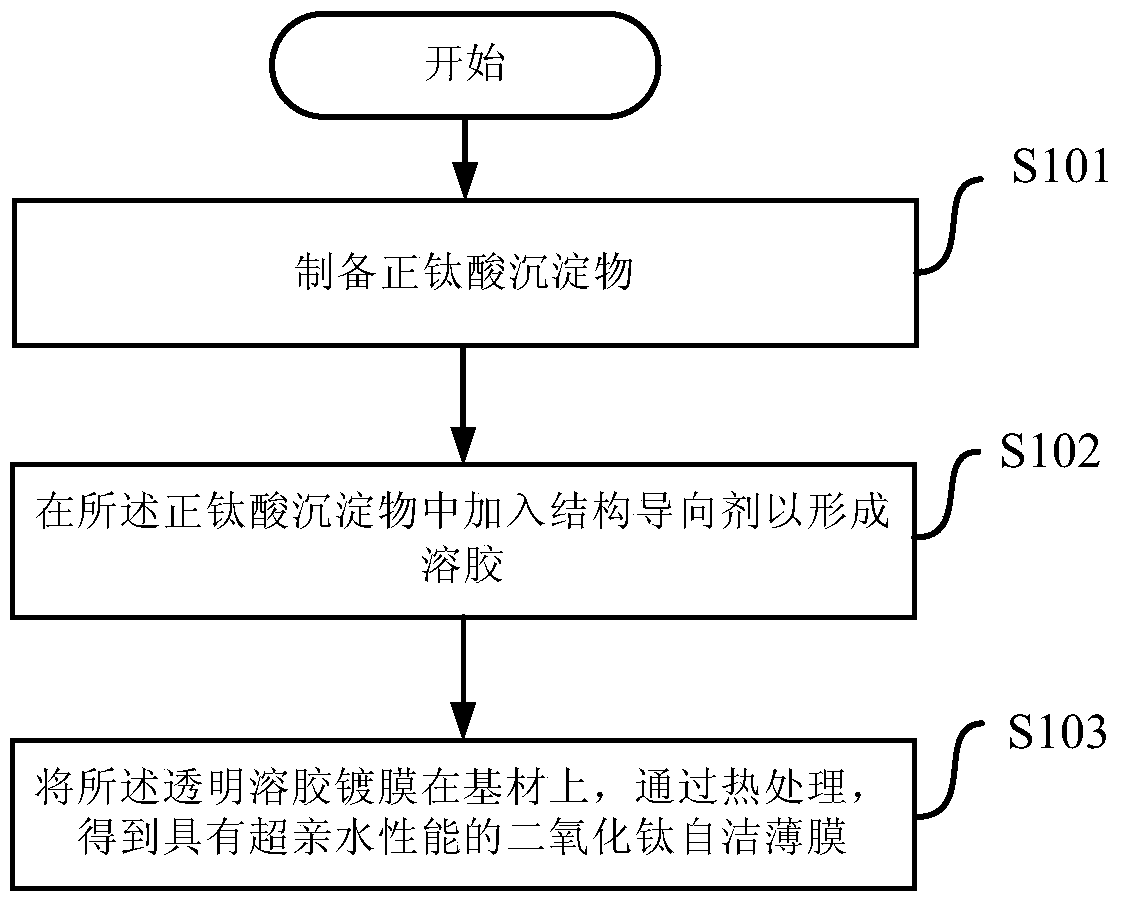

Method used

Image

Examples

preparation example Construction

[0024] In the preparation of the orthotitanic acid precipitate, the titanium tetrachloride aqueous solution is first prepared. Using titanium tetrachloride as a raw material, add titanium tetrachloride from the partial pressure funnel to the aqueous solution dropwise to obtain an aqueous solution of titanium tetrachloride. The amount of titanium tetrachloride and water is 1:1 to 1 : 50, preferably 1:5 to 1:30.

[0025] In the preparation of the titanium dioxide sol, secondly, the titanium tetrachloride aqueous solution and ammonia water are used to prepare the orthotitanic acid precipitate. The titanium tetrachloride aqueous solution was added dropwise to the ammonia water in a partial pressure funnel to obtain a white turbid liquid, wherein the ratio of the titanium tetrachloride aqueous solution to the ammonia water was 1:1 to 1:50, preferably 1:5 ~ 1:30. The white turbid liquid is suction filtered to obtain a white precipitate, which is washed repeatedly with deionized water...

example 1

[0031] Example 1: In an ice-water bath and stirring, add 20 mL of titanium tetrachloride from the partial pressure funnel to 69.2 mL of aqueous solution dropwise to obtain an aqueous solution of titanium tetrachloride; place the aqueous solution of titanium tetrachloride in the partial pressure funnel Add dropwise to 38mL ammonia water to obtain a white turbid liquid. The white turbid liquid is suction filtered to obtain a white precipitate, which is washed repeatedly with deionized water for 6 to 8 times to obtain a precipitation of orthotitanic acid; 400mL of deionized water was used to prepare a dilute slurry with stirring, and then placed in a four-necked flask equipped with a reflux device for condensation, and 96mL of 30% H was added through a partial pressure funnel. 2 O 2 Slowly add dropwise to the slurry and make it dissolve; in addition, 7mLP123 is added to the slurry. Then, it was stirred for 6 hours at 95°C in a water bath, and finally an orange clear and transparent...

example 2

[0032] Example 2: Under ice-water bath and stirring, add 20 mL of titanium tetrachloride from the partial pressure funnel to 69.2 mL of aqueous solution dropwise to obtain an aqueous solution of titanium tetrachloride; put the aqueous solution of titanium tetrachloride in the partial pressure funnel Add dropwise to 38mL ammonia water to obtain a white turbid liquid. The white turbid liquid is suction filtered to obtain a white precipitate, which is washed repeatedly with deionized water for 6 to 8 times to obtain a precipitation of orthotitanic acid; 400mL of deionized water was used to prepare a dilute slurry with stirring, and then placed in a four-necked flask equipped with a reflux device for condensation, and 96mL of 30% H was added through a partial pressure funnel. 2 O 2 Slowly add dropwise to the slurry and make it dissolve; in addition, 0.05g CTAB is added to the slurry. Then, it was stirred for 6 hours at 95°C in a water bath, and finally an orange clear transparent so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com