pulverized coal combustion channel

A pulverized coal combustion and combustion channel technology, which is applied to burners, combustion methods, combustion types, etc., can solve the problems of long production cycle, cumbersome structure, inconvenient maintenance and replacement, etc., and achieves the effect of simple structure, avoidance of coking, and avoidance of NOx.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawings and examples.

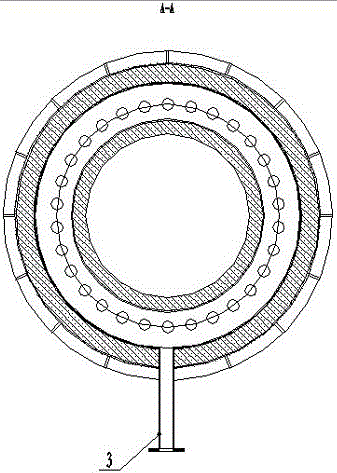

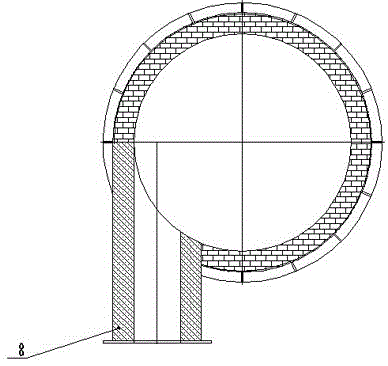

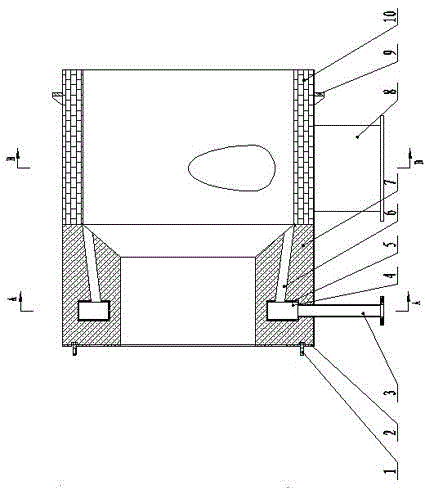

[0022] This embodiment discloses a pulverized coal combustion passage, which is mainly composed of a flame expansion section and a flame stabilization section. The pulverized coal combustion channel is used in conjunction with the pulverized coal burner and the pulverized coal boiler. See attached for specific structure Figure 1-3 .

[0023] See figure 1 and figure 2 , the flame expansion section is made of castables with a temperature resistance of 1500°C, and is mainly composed of the furnace front flange 2, the tertiary air inlet pipeline 3, the tertiary air gas collection ring 4, the tertiary air gas collection ring rear end plate 5, and the tertiary air oblique The long nozzle hole 6 and the pouring material 7 are composed. The main structure of the flame expansion section composed of the pouring material 7 is cylindrical, and the part connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com