Quick determination method for cadmium element in grains with X-ray fluorescent spectrometry

A fluorescence spectrometry and rapid determination technology, applied in the field of heavy metal determination in grains, can solve the problems that the detection accuracy and repeatability are not as good as the spectrometry method, the processing time is long, time-consuming and labor-intensive, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments described below are exemplary, and are only for explaining the present invention, and should not be construed as limiting the present invention.

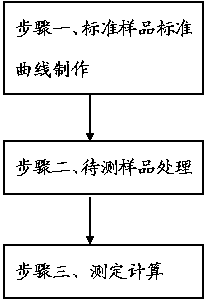

[0033] The X fluorescence spectrometry method of the present invention will be described below with reference to accompanying drawing to the rapid determination method of cadmium element in grain, wherein figure 1 is a flowchart of the present invention.

[0034] According to an embodiment of the present invention, such as figure 1 Shown, the X fluorescence spectrometry provided by the present invention comprises to the rapid determination method of cadmium element in grain:

[0035] Step 1. Preparation of standard sample standard curve: A series of cadmium grain powders with standard content gradients are sieved respectively, put into sample cups and compacted;

[0036] Scan a series of standard samples on the computer to obtain the X-ray fluorescence intensity of standard samples with known content, and ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com