Wrapping paste supplemented with bamboo shoot dietary fiber, application thereof and fish ball prepared from the same

A technology of bamboo shoot dietary fiber and wrapping paste, applied in the direction of bacteria used in food preparation, food preparation, application, etc., can solve the problems of underutilization of leftovers, easy corruption and odor of leftovers, environmental pollution, etc., and achieve product The effect of short drying time, good appearance and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

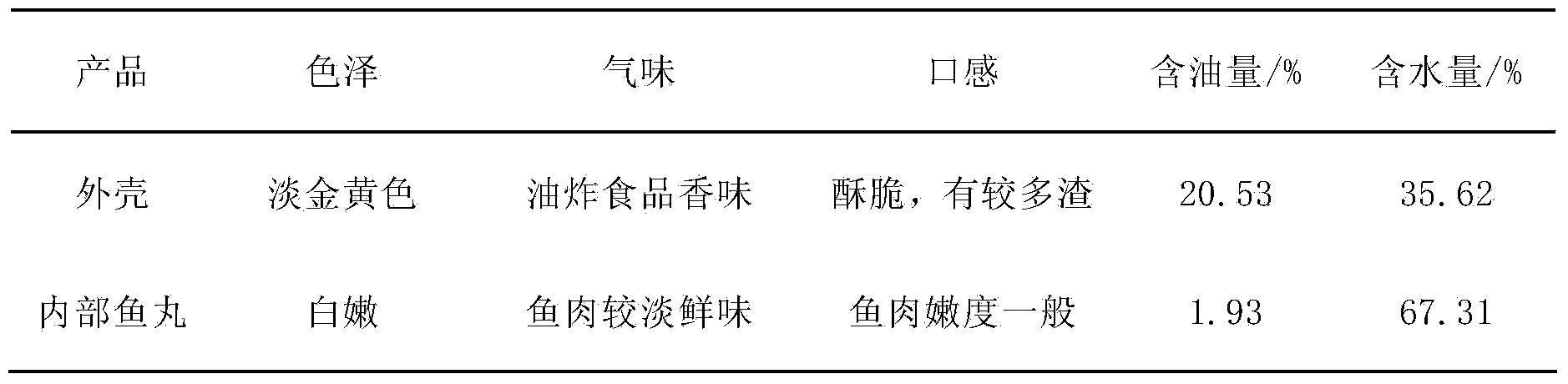

Embodiment 1

[0030] 1) Thaw 200g of frozen silver carp mince, cut into small pieces, chop and mix, marinate, season and make minced fish. Take by weighing 150g chopped and mixed surimi, and make 15 fish balls with a weight of about 10g and the same size.

[0031] 2) Add 50g of all-purpose flour, 30g of glutinous rice starch, 10g of egg white powder, 1g of baking powder, and 1g of salt into 90g of water to make a paste, then add 2g of thunder bamboo shoot dietary fiber powder prepared by crushing and passing through a 100-mesh sieve , modulated into a uniform wrapping paste.

[0032] 3) Put the prepared fish balls into the evenly mixed batter to ensure that the outer surface of the fish balls is in full contact with the batter, slowly take it out after immersion for 10 seconds, pour it for 15 seconds, put it into the batter again and do the second step in the same way. The first paste and the third paste. Take out the fish balls, drop them into the bread crumbs until the batter is not for...

Embodiment 2

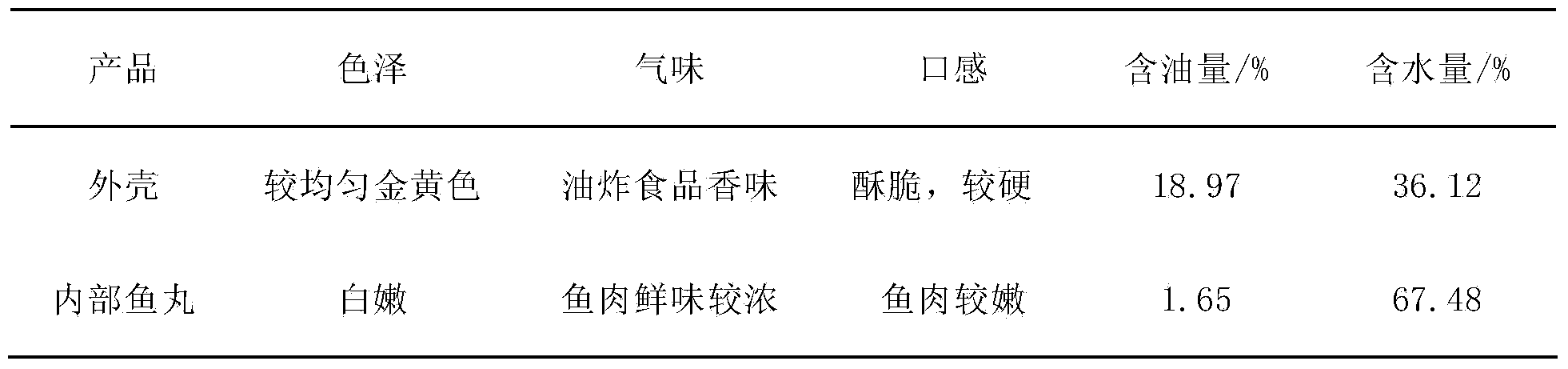

[0038] 1) The fish ball production process is the same as step 1) in the implementation case 1.

[0039] 2) First add 50g of all-purpose flour, 30g of glutinous rice starch, 10g of egg white powder, 1g of baking powder, and 1g of salt into 90g of water to make a paste, then add 4g of Lei bamboo shoot dietary fiber powder prepared by crushing and passing through an 80-mesh sieve , modulated into a uniform wrapping paste.

[0040]3) Put the prepared fish balls into the evenly mixed batter to ensure that the outer surface of the fish balls is fully in contact with the batter, slowly take it out after immersion for 10 seconds, pour it into the batter for 15 seconds, and then put it into the batter for the second time in the same way. The first paste and the third paste. Take out the fish balls, wait until the batter does not form into strands, drop them, and put them in the bread crumbs,

[0041] Make the bread crumbs evenly cover the surface of the fish balls.

[0042] 4) The ...

Embodiment 3

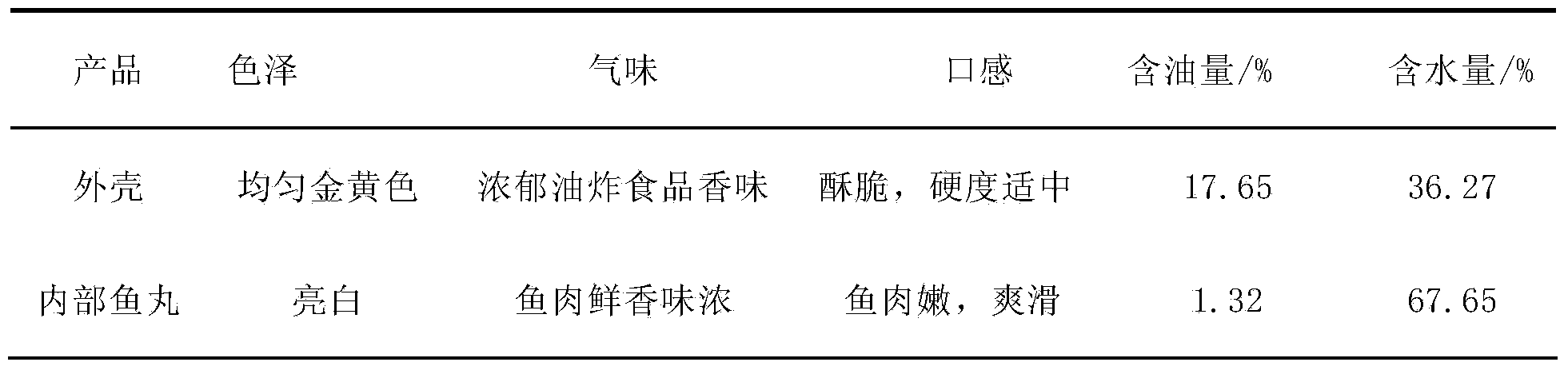

[0047] 1) The fish ball production process is the same as step 1) in the implementation case 1.

[0048] 2) First add 50g of all-purpose flour, 30g of glutinous rice starch, 10g of egg white powder, 1g of baking powder, and 1g of salt into 90g of water to make a paste, then add 6g of Lei bamboo shoot dietary fiber powder prepared by crushing and passing through an 80-mesh sieve , modulated into a uniform wrapping paste.

[0049] 3) Put the prepared fish balls into the evenly mixed batter to ensure that the outer surface of the fish balls is fully in contact with the batter, slowly take it out after immersion for 10 seconds, pour it into the batter for 15 seconds, and then put it into the batter for the second time in the same way. The first paste and the third paste. Take out the fish balls, drop them into the bread crumbs until the batter is not formed into strands, so that the bread crumbs evenly cover the surface of the fish balls.

[0050] 4) The frying process is the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com