Preparation method of reverse osmosis membrane with high throughput and high salt retention rate

A technology of reverse osmosis membrane and rejection rate, which is applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problem of low permeation flux, improve permeation flux, rational design, improve and eliminate salt rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

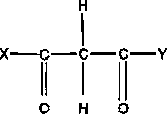

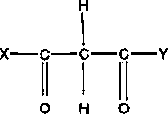

[0017] First, the polysulfone porous membrane was immersed in m-phenylenediamine with a concentration of 1wt / v%, and Et with a concentration of 0.1wt / v%. 3 NH(F 6 acac) 2 Immerse in the aqueous solution for 0.5 minutes, take out and remove the excess solution on the surface; then immerse it in the n-hexane solution of trimesoyl chloride monomer with a concentration of 0.1wt / v%, and react for 1 minute; then at 40 o C curing 20 minutes in the oven, molding.

[0018] This film is at 25 o C, under the pressure of 0.8MPa, the separation results for 30000ppm NaCl aqueous solution are: the salt rejection rate is 99.6%, and the water flux is 37 L.m -2 .h -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com