Quick plug-in pipe multi-point synchronous automatic welding welding unit

A welding unit, synchronous automatic technology, applied in the direction of welding accessories, welding equipment, welding equipment, etc., can solve the problems of incomplete fusion, incomplete penetration, discontinuous weld bead and undercut of the weld layer, and achieve rapid installation and disassembly , Short welding preparation time, easy and convenient wire replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

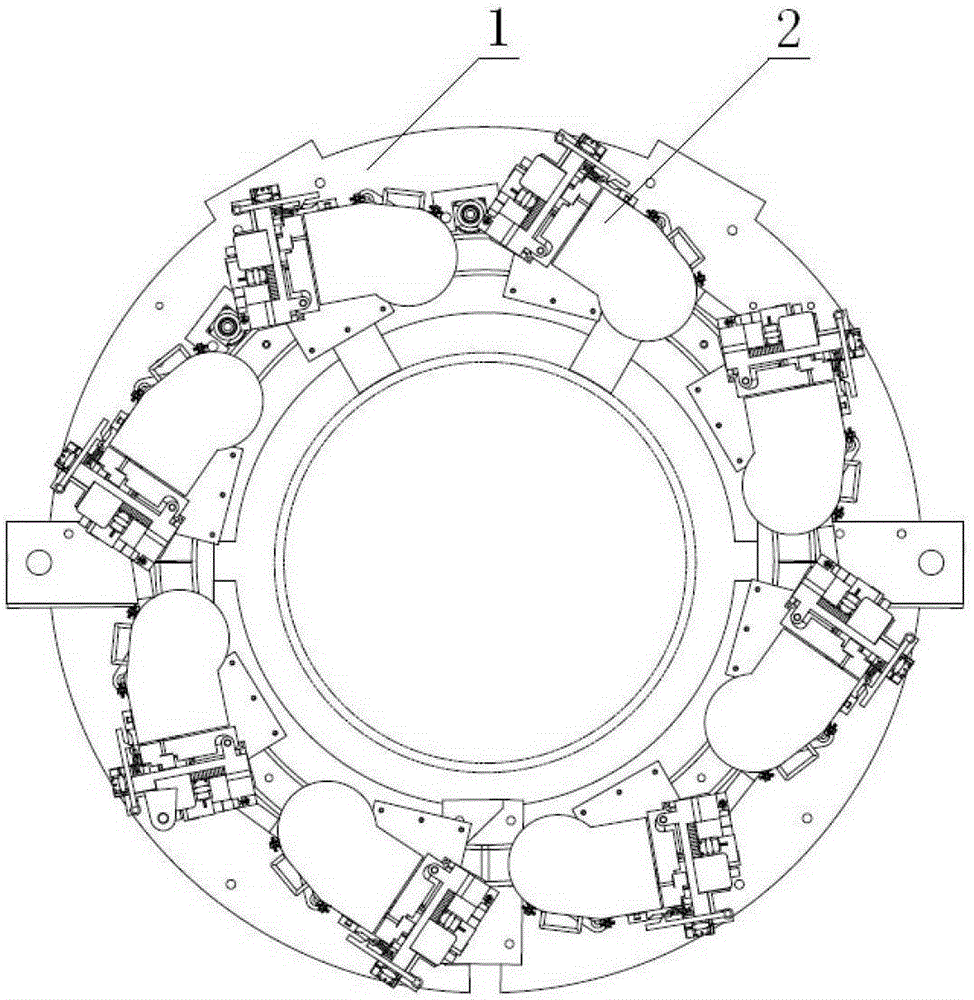

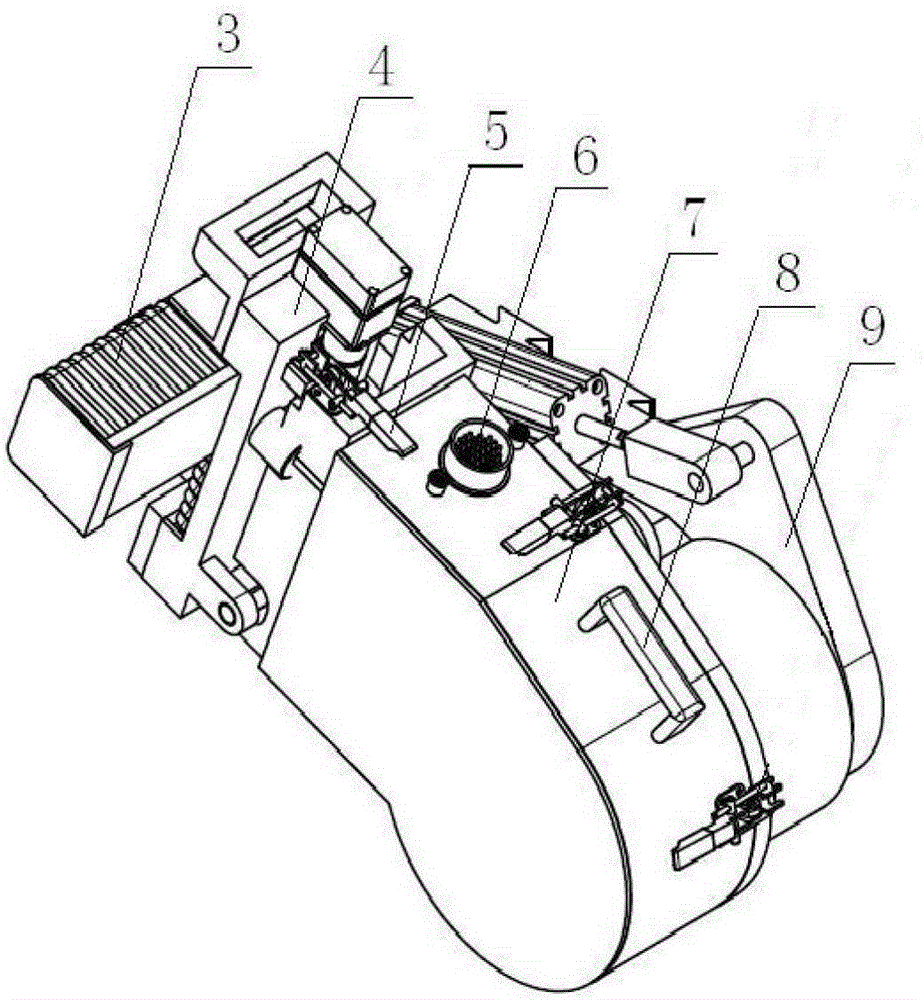

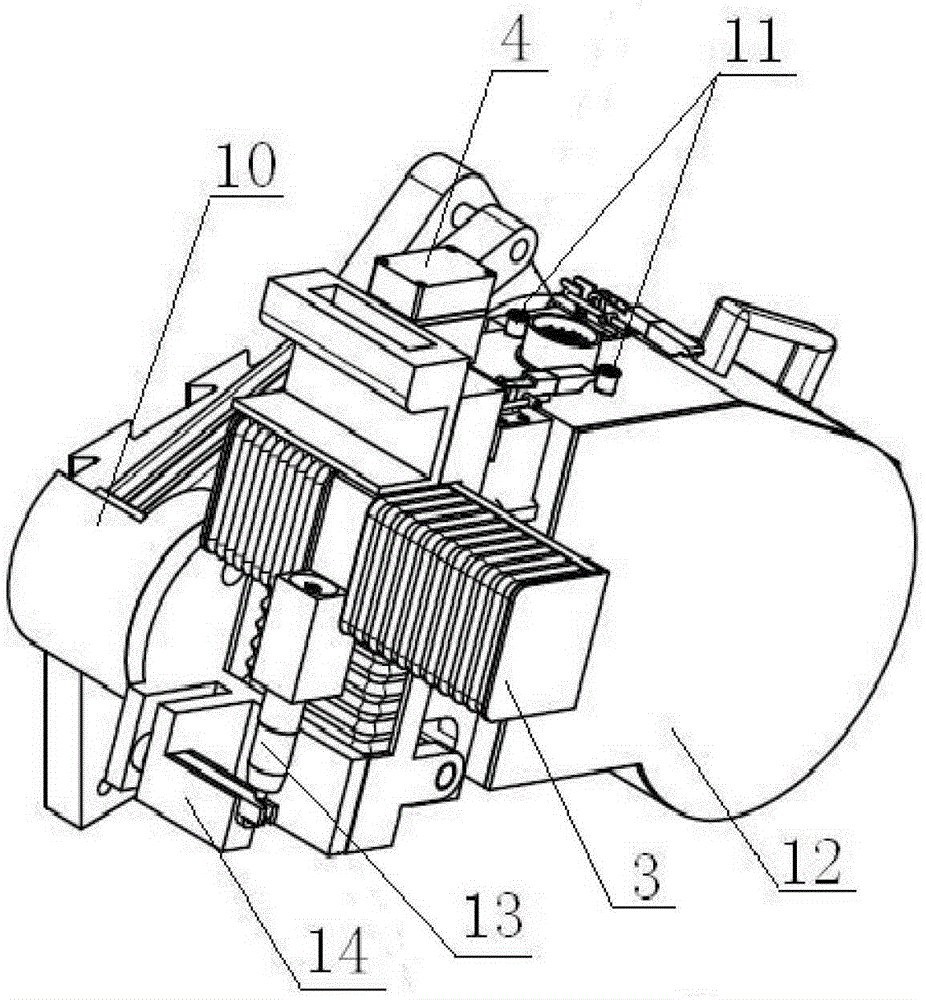

[0020] refer to Figures 1 to 9 Embodiments of the present invention are further described:

[0021] Such as Figure 2a , 2b As shown in and 2c, the welding unit 2 is composed of a welding torch left and right adjustment mechanism 3, a welding torch up and down adjustment mechanism 4, a pneumatic lifting mechanism 10, a wire feeding mechanism 12, a welding torch 13 and an automatic wire cutting mechanism 14:

[0022] Such as figure 1 , Figure 2c and image 3 As shown, the pneumatic lifting mechanism 10 includes a connecting plate 9, a swing arm 19, a fixed groove plate 20, a cylinder 21, a piston rod 22, a connecting block 23, a rotatable connecting shaft 24 and a connecting shaft 15: the connecting plate 9 passes through the Dovetail guide rail 16 connects welding machine main body 1, and is connected with the swing arm 19 that is positioned at its other end face by connecting shaft 15, can rotate relative to it; The rotating connecting shaft 24 is connected with the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com