Phenyl-series high-refractive-index LED loading glue and preparation method thereof

A high-refractive index, phenyl-based technology, applied in adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems that affect the service life and luminous performance of LEDs, easy yellowing, heat resistance, and weather resistance and poor moisture resistance, etc., to achieve good encapsulation effect, sufficient curing process, and good bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

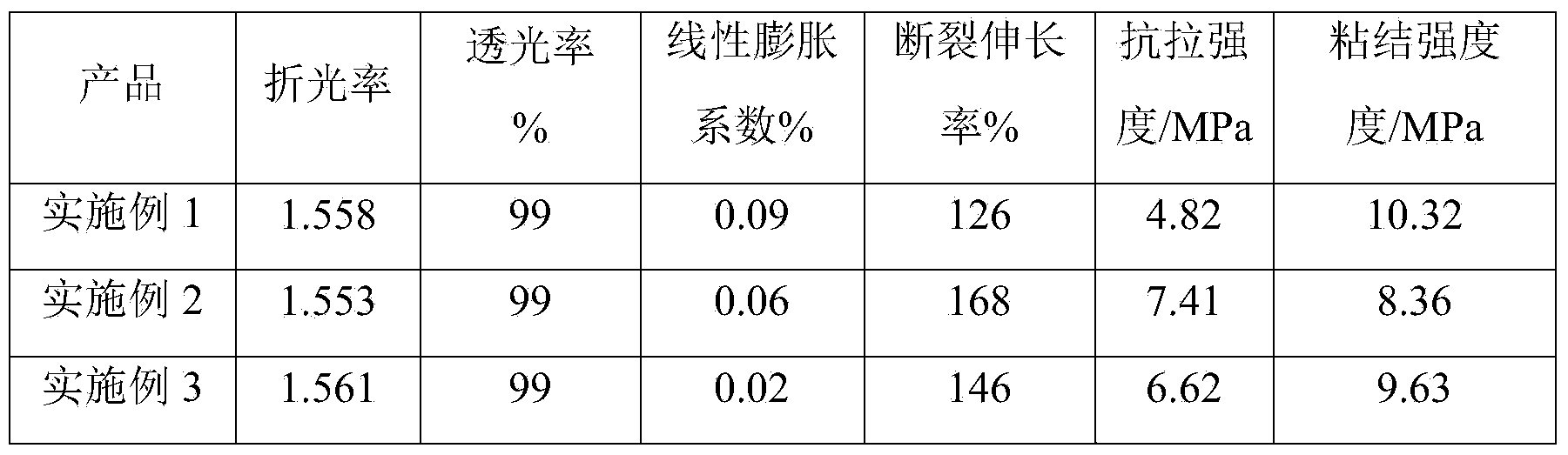

Examples

Embodiment 1

[0035] (1) The synthetic method step of vinyl-containing polysiloxane in A component is as follows:

[0036] Add 40g of phenyltrimethoxysilane, 30g of diphenyldimethoxysilane, 20g of tetramethyldivinyl disiloxane, 5g of silane coupling agent KH-570 to a 250ml round bottom flask, Mix evenly, add 9.5g ethanol as solvent, then add 0.5g tetrabutylammonium hydroxide, heat and stir at 80°C for 2h, stop heating, add 0.1g trifluoromethanesulfonic acid and continue stirring at 80°C for 4h, stop heating, stand still Set aside to cool, wash the oil phase with water until neutral, and distill under reduced pressure to obtain a colorless and transparent vinyl-containing polysiloxane.

[0037] (2) The synthetic method step of hydrogen-containing polysiloxane in the B component is as follows:

[0038] Add 50g of phenyltrimethoxysilane, 25g of diphenyldimethoxysilane, 10g of tetramethyldihydrogendisiloxane, 0.5g of silane coupling agent KH-560 to a 250ml round bottom flask, Mix well, add 8....

Embodiment 2

[0046] (1) The synthetic method step of vinyl-containing polysiloxane in A component is as follows:

[0047] Add 20g of phenyltrimethoxysilane, 60g of diphenyldimethoxysilane, 20g of tetramethyldivinyl disiloxane, 2g of silane coupling agent KH-570 to a 250ml round bottom flask, Mix well, add 5.1g ethanol as solvent, then add 0.5g tetrabutylammonium hydroxide, heat and stir at 120°C for 2h, stop heating, add 0.1g trifluoromethanesulfonic acid and continue stirring at 120°C for 4h, stop heating, Set aside to cool, wash the oil phase with water until neutral, and distill under reduced pressure to obtain a colorless and transparent vinyl-containing polysiloxane.

[0048] (2) The synthetic method step of hydrogen-containing polysiloxane in the B component is as follows:

[0049]Add 10g of phenyltrimethoxysilane, 40g of diphenyldimethoxysilane, 10g of tetramethyldihydrogendisiloxane, and 0.5g of KH-560 to a 250ml round-bottomed flask, mix well, and add 3g ethanol as solvent, then...

Embodiment 3

[0057] (1) The synthetic method step of vinyl-containing polysiloxane in A component is as follows:

[0058] Add 30g of phenyltrimethoxysilane, 60g of diphenyldimethoxysilane, 20g of tetramethyldivinyl disiloxane, 5g of silane coupling agent KH-570 to a 250ml round bottom flask, Mix well, add 8g ethanol as solvent, then add 0.5g tetrabutylammonium hydroxide, heat and stir at 100°C for 2h, stop heating, add 0.1g trifluoromethanesulfonic acid, continue stirring at 100°C for 4h, stop heating, let stand After cooling, the oil phase was washed with water until neutral, and distilled under reduced pressure to obtain a colorless and transparent vinyl-containing polysiloxane.

[0059] (2) The synthetic method step of hydrogen-containing polysiloxane in the B component is as follows:

[0060] Add 100g of phenyltrimethoxysilane, 15g of diphenyldimethoxysilane, 18g of tetramethyldihydrogendisiloxane, and 0.9g of KH-560 to a 250ml round-bottomed flask, mix well, and add 9g ethanol as so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com