A visual wheel tube device for evaluating the performance of hydrate inhibitors

A hydrate inhibitor and wheel tube technology, which can be applied to measurement devices, instruments, scientific instruments, etc., can solve the problems of high gas consumption, complicated operation, large investment, etc., and achieve the effect of being suitable for screening and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Concrete operation steps of the present invention are as follows:

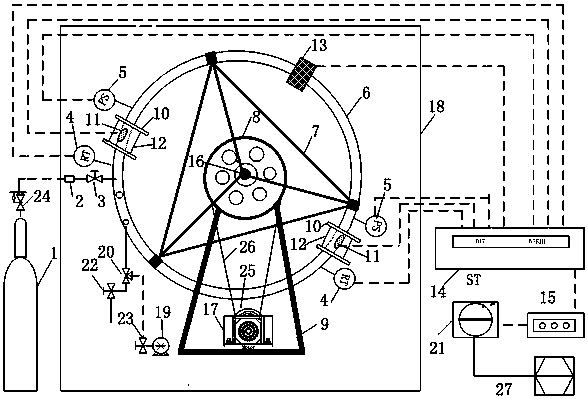

[0050] (1) Close the inlet valve (3) and liquid inlet valve (22), open the three-way valve (20) and air valve (23), and turn on the vacuum pump (19) to vacuum for about 1 minute.

[0051] (2) After vacuuming, close the valve (23) connected to the vacuum pump, put the prepared 600ml solution containing 1wt% PVPK90 into the liquid inlet, open the liquid inlet valve (22), and the solution is sucked into the high-pressure stainless steel tube reactor (6), close the inlet valve (22).

[0052] (3) Open the intake valve (3), feed the mixed gas simulating the real gas field into the high-pressure stainless steel coil reactor (6), and pass through the pressure reducing valve (24) on the gas cylinder and the high-pressure stainless steel coil reactor. The output signal of the pressure sensor is used to judge and control the pressure of the incoming gas, and a 7.2MPa mixed gas (containing more than ten kinds of g...

Embodiment 2

[0063] The difference between this example and Example 1 is the performance evaluation of the combination of the kinetic inhibitor PVP K90 and the thermodynamic inhibitor MEG. Under the same experimental conditions as in Example 1, within 24 hours of the experiment, the results transmitted from the output torque signal, sapphire window, pipeline endoscope, and temperature and pressure signals were not found to add 1wt%PVP K90+10wt%MEG. Hydrate formation.

Embodiment 3

[0065] The difference between this example and Example 1 and Example 2 is the evaluation of the inhibitory effect of anti-aggregation KL-1. Under the same experimental conditions as in Example 1 and Example 2, the 600ml solution containing 1wt% KL-1 was sucked into the high-pressure stainless steel wheel tube reactor, and after filling the mixed gas of 7.2MPa, after the temperature and pressure signals stabilized, Set the temperature of the temperature-controlled freezer to 3 °C. Judging from the temperature and pressure signals, sapphire window and torque output signals, the 1wt% KL-1 solution was found to have hydrate formation in 2.3 hours, and the torque output signal changed suddenly from 0.1 Nm in the stable section to 3.0Nm. Judging from the signal transmitted by the online particle analyzer, the time from hydrate generation to complete blockage of the pipeline is 12.1 hours. During the period of hydrate slurry flow, the particle size of hydrate particles gradually grow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com