Two-dimensional heterojunction solar cell and manufacturing method thereof

A technology of solar cells and two-dimensional heterojunctions, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as low efficiency, high cost, and complex structure of solar cells, and achieve improved efficiency, wide application price, and enhanced The effect on the ability of electron transport and charge migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

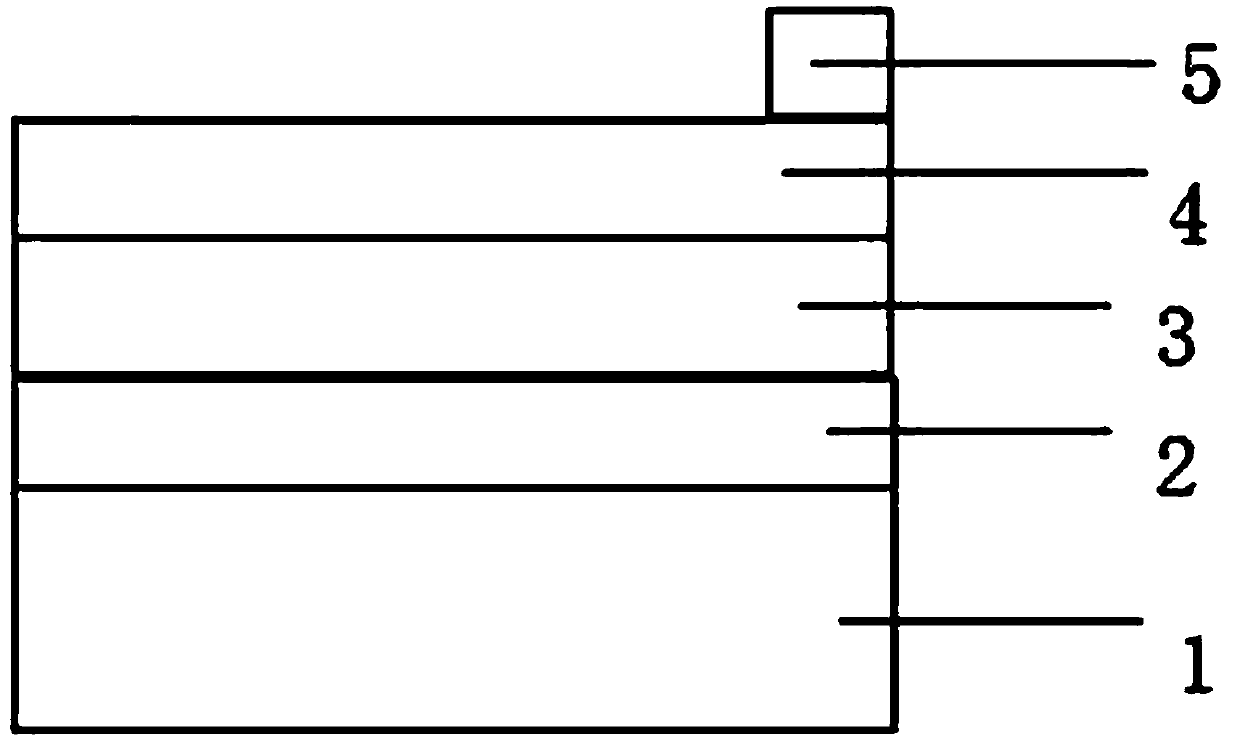

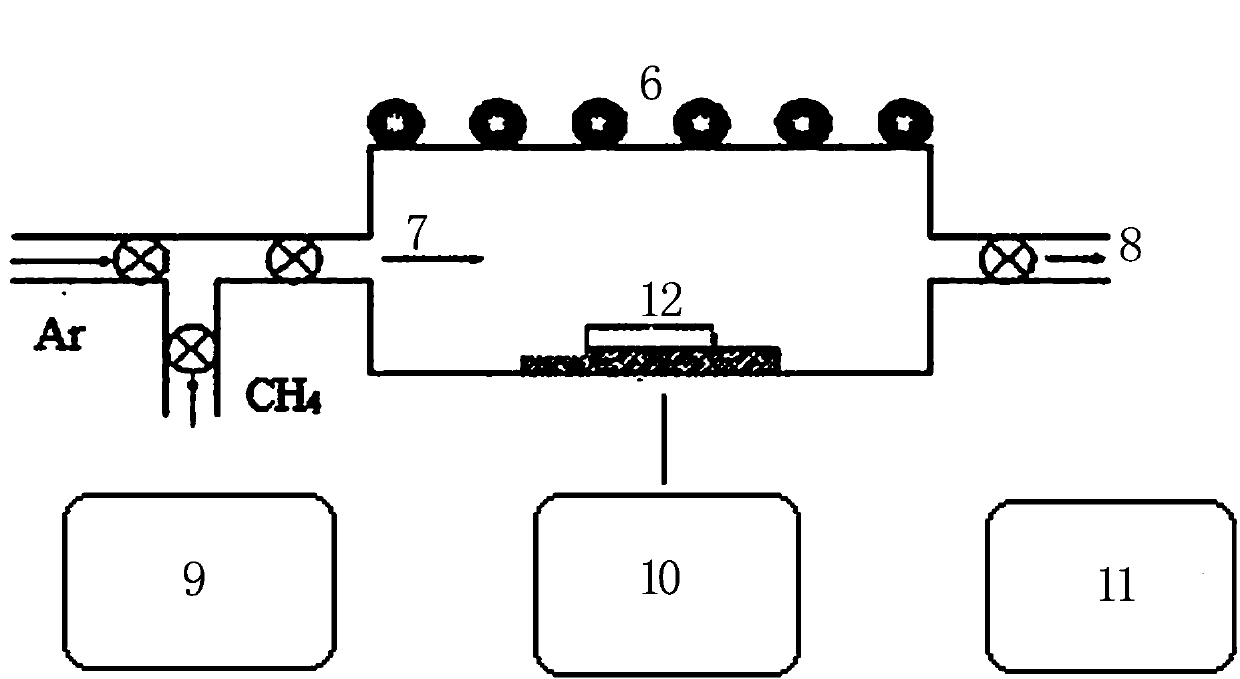

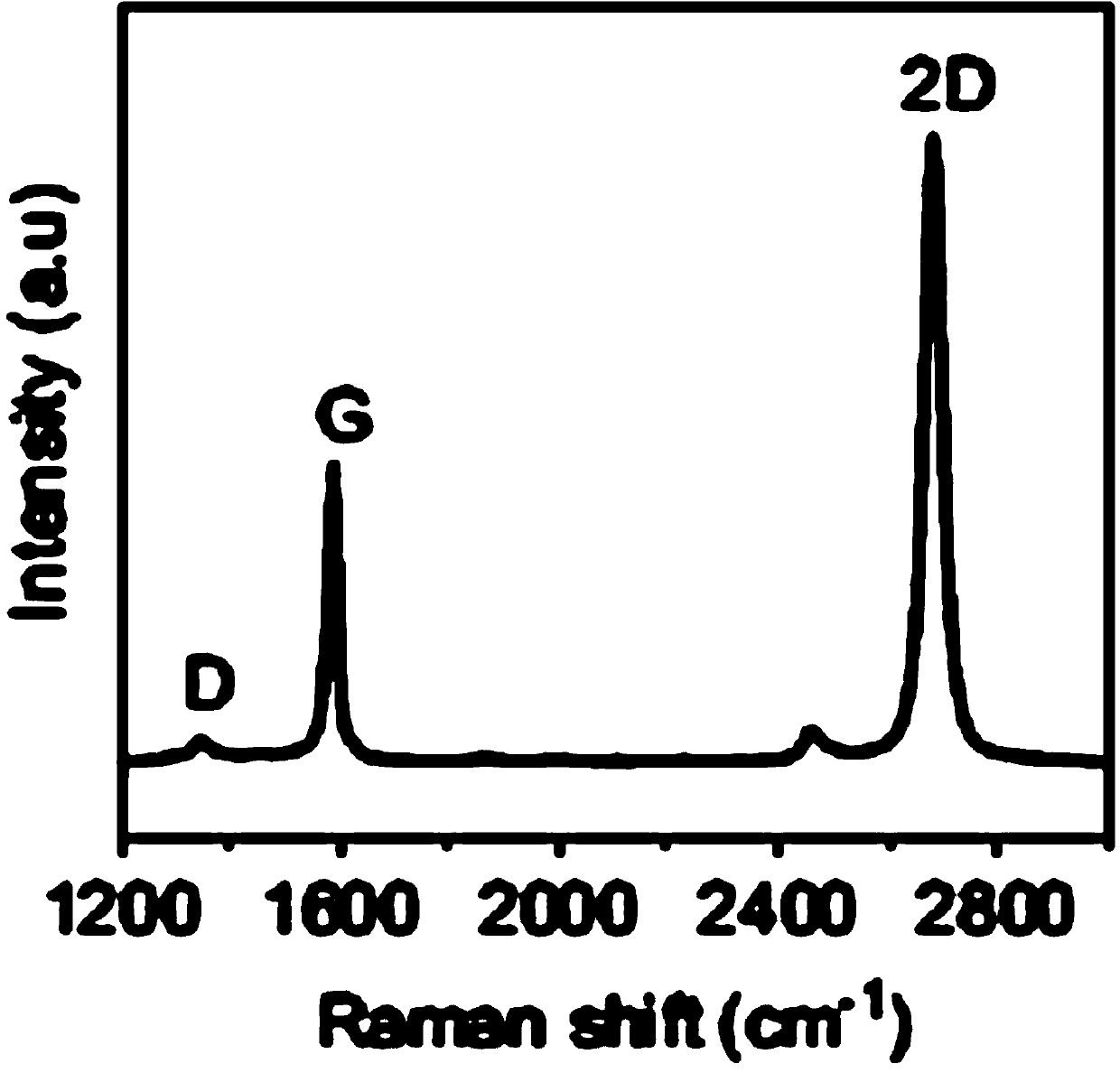

[0030] Embodiment 1 A kind of preparation method of two-dimensional heterojunction solar cell, comprises the following steps: a, the preparation of high transmittance, high conductivity graphene:

[0031] (1) A uniform graphene film was grown on a Cu foil with a thickness of 50 μm by atmospheric pressure chemical vapor deposition;

[0032] (2) the Cu foil that grows graphene film is placed on the homogenizer, drip-coats polymethyl methacrylate (PMMA organic solvent) on the surface of Cu foil that grows graphene film, starts glue homogenizer, rotating speed 4000rpm, Make the PMMA evenly cover the upper surface of the Cu foil, then place the Cu foil on a heating platform at a temperature of 170°C for 3 minutes, and dry the PMMA solvent;

[0033] (3) Put the above-mentioned Cu foil coated with PMMA solvent into FeCl with a concentration of 0.5M 3 Corrosion in solution to remove Cu matrix;

[0034] (4) Use Si / SiO 2 The substrate was picked up and rinsed in deionized water for 1...

Embodiment 2

[0046] Embodiment 2 A preparation method of a two-dimensional heterojunction solar cell, comprising the steps of: a, preparation of high transmittance, high conductivity graphene:

[0047] (1) A uniform graphene film was grown on a Cu foil with a thickness of 50 μm by atmospheric pressure chemical vapor deposition;

[0048] (2) the Cu foil that grows graphene film is placed on the homogenizer, drip-coats polymethyl methacrylate (PMMA organic solvent) on the surface of Cu foil that grows graphene film, starts glue homogenizer, rotating speed 4000rpm, Make the PMMA evenly cover the upper surface of the Cu foil, then place the Cu foil on a heating platform at a temperature of 150°C for 5 minutes, and dry the PMMA solvent;

[0049] (3) Put the above-mentioned Cu foil coated with PMMA solvent into FeCl with a concentration of 0.5M 3 Corrosion in solution to remove Cu matrix;

[0050] (4) Use Si / SiO 2 For the substrate, the graphene film was picked up and rinsed in deionized wate...

Embodiment 3

[0062] Embodiment 3 A kind of preparation method of two-dimensional heterojunction solar cell, comprises the following steps: a, the preparation of high transmittance, high conductivity graphene:

[0063] (1) A uniform graphene film was grown on a Cu foil with a thickness of 50 μm by atmospheric pressure chemical vapor deposition;

[0064] (2) the Cu foil that grows graphene film is placed on the homogenizer, drip-coats polymethyl methacrylate (PMMA organic solvent) on the surface of Cu foil that grows graphene film, starts glue homogenizer, rotating speed 4000rpm, Make the PMMA evenly cover the upper surface of the Cu foil, then place the Cu foil on a heating platform at a temperature of 200°C for 2 minutes, and dry the PMMA solvent;

[0065] (3) Put the above-mentioned Cu foil coated with PMMA solvent into FeCl with a concentration of 0.5M 3 Corrosion in solution to remove Cu matrix;

[0066] (4) Use Si / SiO 2 For the substrate, pick up the graphene film and rinse it in de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electron work function | aaaaa | aaaaa |

| electron work function | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com