Method for manufacturing nanometer laser device arrays

A technology of nano-laser and manufacturing method, which is applied in the field of optics, can solve the problems of adding nano-laser components, inability to realize flexible manipulation of lasers, and difficulty in nano-laser arrays, so as to achieve difficult manufacturing process, poor flexibility in array distribution, and reliable performance sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

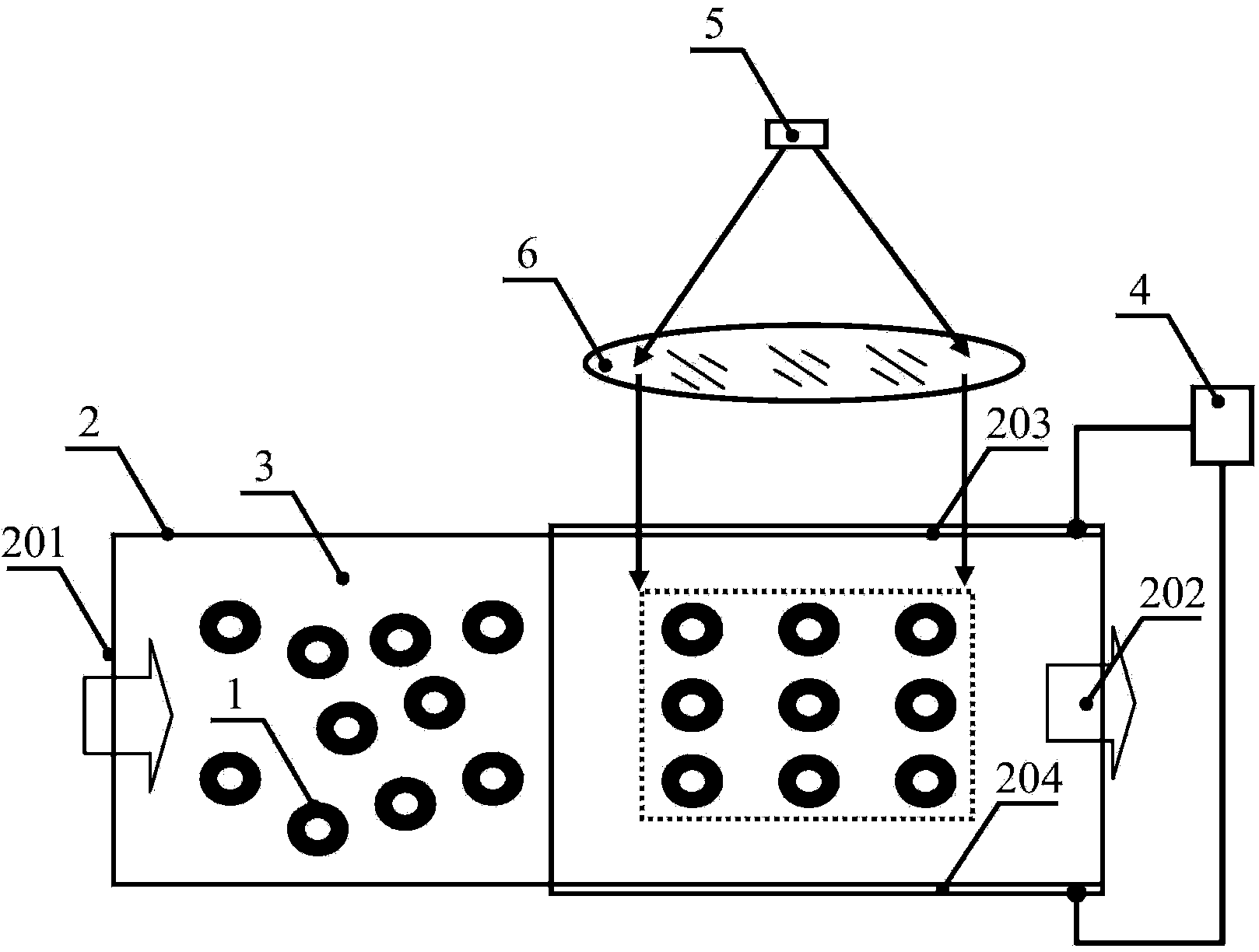

[0025] The present invention will be further described below in conjunction with drawings and embodiments.

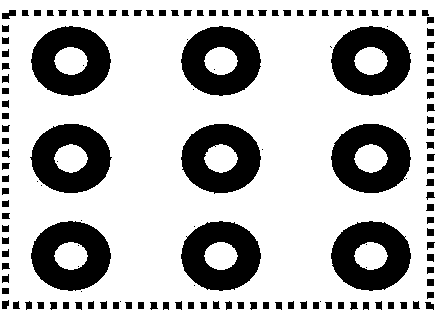

[0026] The present invention is based on the interaction mechanism of multilayer spherical shell nano optics and plasma modes, adopts multilayer spherical shell nano lasers, combines electrorheological effects to arrange and solidify the nano lasers, obtains nano laser arrays, and provides a nano laser Array production method, the specific production steps are as follows:

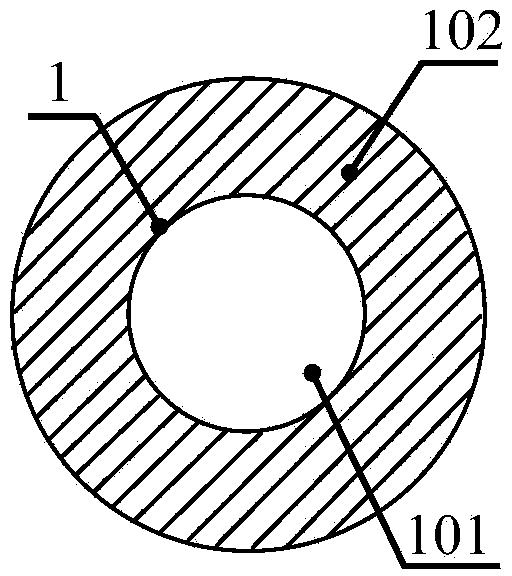

[0027] Step (1) Dispersing the nano-laser 1 into the photocurable glue fluid 3 to form a nano-laser suspension, a single nano-laser adopts a spherical shell structure, including a metal sphere core 101 and a non-metallic outer spherical shell 102 doped with dye molecules, And the radius of the metal sphere core 101 is less than 100 nanometers, and the number of dye molecules contained in the non-metal outer spherical shell 102 is greater than 2000;

[0028] In this embodiment, the nano-laser consist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com