Automotive alternator stator assembly

A technology of alternator and stator assembly, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit static parts, winding conductor shape/style/structure, etc., which can solve large investment, low production efficiency and low yield , process difficulty and other problems, to achieve the effect of reducing production cost, improving production efficiency and breaking technical barriers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

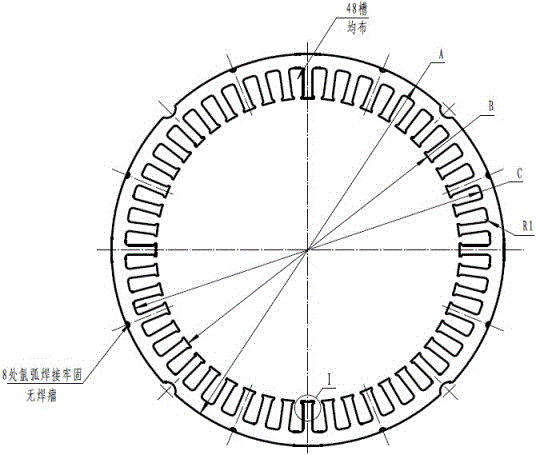

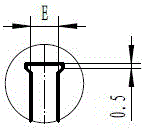

[0025] This embodiment is an output power 14 volts 120 stabilizer assembly, using the stator core of the above structure, refer to the attached Figure 4 , The stator coil 4 is a single three-phase delta connection, the diameter of the round copper enameled wire is 1.1 to 1.2 mm, and there are 16 wires in each stator core slot.

[0026] skills requirement

[0027] 1. The three-phase starters A 1 - B 1 1 - C 2 7 slots are embedded below, and the tail wires are from X 1 6 - Y 2 6 - Z 4 8. The stator windings are connected in delta, and the pitch q = 1 - 4. φ1.1 5 pairs of wires have 8 turns per slot.

[0028] 2. The winding is dripped with 0 8 4 0 - 1 H heat-resistant polyester resin paint (Jiaxing Qinghe).

[0029] 3. Winding insulation resistance ≥ 2 0 MΩ. The compressive strength is 5 0 H Z, 6 6 0 V, 1 S without breakdown.

[0030] 4. The inter-turn and phase-to-phase impulse withstand voltage test of the winding, the peak value of the impulse voltage is 1 0 0 0 V, and th...

Embodiment 2

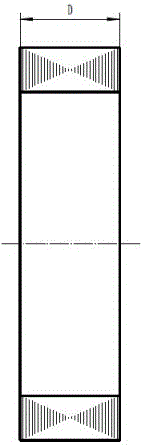

[0032] This embodiment is an output power of 14 volts 150 stabilizer assembly, refer to the attached Figure 5-6 , The stator coil 4 is two sets of independent three-phase delta connections, the diameter of the round copper enameled wire is 1.2 to 1.3 mm, and there are 14 wires in each stator core slot.

[0033] skills requirement

[0034] 1. The stator windings are two sets of independent delta connection, pitch q = 1 - 4, 7 turns of φ1.25 high temperature wire, the first group of three-phase start A 1 - B 3 - C 1 1 slot is embedded below, The tail wire comes from X 4 - Y 1 2 - Z 2, the second group of three phases starts from a 1 7 - b 2 1 - c 2 5 grooves and the tail wire comes from x 2 6 - y 1 8 - z 2 2.

[0035] 2. The winding is dripped with 0840-1H heat-resistant polyester resin paint (Jiaxing Qinghe).

[0036] 3. Winding insulation resistance ≥ 2 0 MΩ. The compressive strength is 5 0 H Z, 6 6 0 V, 1 S without breakdown.

[0037] 4. The inter-turn and phase-to-phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com