Fired water-permeable paving brick based on used sodium silicate sand and preparation method of paving brick

A technology of water glass and pavement bricks, which is applied in the field of water glass old sand-based permeable sintered pavement bricks and its preparation, which can solve the problems of air heat and humidity exchange, urban groundwater level drop, waste of limited resources, etc., and reduce firing temperature, lower eutectic temperature, and lower energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

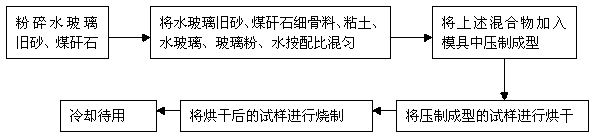

Image

Examples

Embodiment 1

[0030] A water-glass old sand-based permeable sintered pavement brick. The raw material composition and proportion of the permeable pavement brick: water glass old sand is primary used sand, and the dominant mineral of clay is kaolinite. The proportion is: water glass old sand 892.5 g, coal gangue 52.5g, clay 31.5g, water glass 21g, glass powder 31.5g, water 21g.

[0031] The preparation method of the above-mentioned water glass old sand-based permeable sintered pavement brick comprises the following steps:

[0032] (1) Pulverization: Put the old water glass sand and coal gangue into a pulverizer to crush them into fine aggregates. The fineness modulus of the old water glass sand after crushing is 2.0, and the particle size of the coal gangue after crushing is 0.15mm~0.6mm;

[0033] (2) Mixing: Fully mix the above-mentioned raw materials except water glass and water according to the ratio, stir evenly, add water glass and water for wet mixing, and age the evenly mixed ingredie...

Embodiment 2

[0038] A water-glass old sand-based permeable sintered pavement brick, the raw material composition and proportion of the water-permeable pavement brick: water glass old sand is quaternary old sand, the dominant mineral of clay is montmorillonite, and the proportion is: water glass old sand 525g, coal gangue 157.5g, clay 157.5g, water glass 31.5g, glass powder 157.5g, water 21g.

[0039] The preparation method of the above-mentioned water glass old sand-based permeable sintered pavement brick comprises the following steps:

[0040] (1) Pulverization: Put the old water glass sand and coal gangue into a pulverizer to crush them into fine aggregates. The fineness modulus of the old water glass sand after crushing is 2.5, and the particle size of the coal gangue after crushing is 0.15mm~0.6mm;

[0041] (2) Mixing: Fully mix the above-mentioned raw materials except water glass and water according to the ratio, stir evenly, add water glass and water for wet mixing, and age the evenl...

Embodiment 3

[0046] A water-glass old sand-based permeable sintered pavement brick. The raw material composition and proportion of the permeable pavement brick: water glass old sand is tertiary old sand, and the dominant mineral of clay is kaolinite. The proportion is: water glass old sand 682.5 g, coal gangue 210g, clay 42g, water glass 52.5g, glass powder 42g, water 21g.

[0047] The preparation method of the above-mentioned water glass old sand-based permeable sintered pavement brick comprises the following steps:

[0048] (1) Pulverization: Put the old water glass sand and coal gangue into a pulverizer to crush them into fine aggregates. The fineness modulus of the old water glass sand after crushing is 2.3, and the particle size of the coal gangue after crushing is 0.15mm~0.6mm;

[0049] (2) Mixing: Fully mix the above-mentioned raw materials except water glass and water according to the ratio, stir evenly, add water glass and water for wet mixing, and age the evenly mixed ingredients...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Splitting tensile strength | aaaaa | aaaaa |

| Water permeability coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com