Novel energy-saving three-tower continuous extractive distillation technology and extractive distillation system thereof

A technology of extractive distillation and extractive distillation tower, which is applied in the field of new energy-saving three-tower continuous extractive distillation process and its extractive distillation system, which can solve the problems of relative volatility decrease, excessive energy, consumption, etc., and reduce consumption , small investment, simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

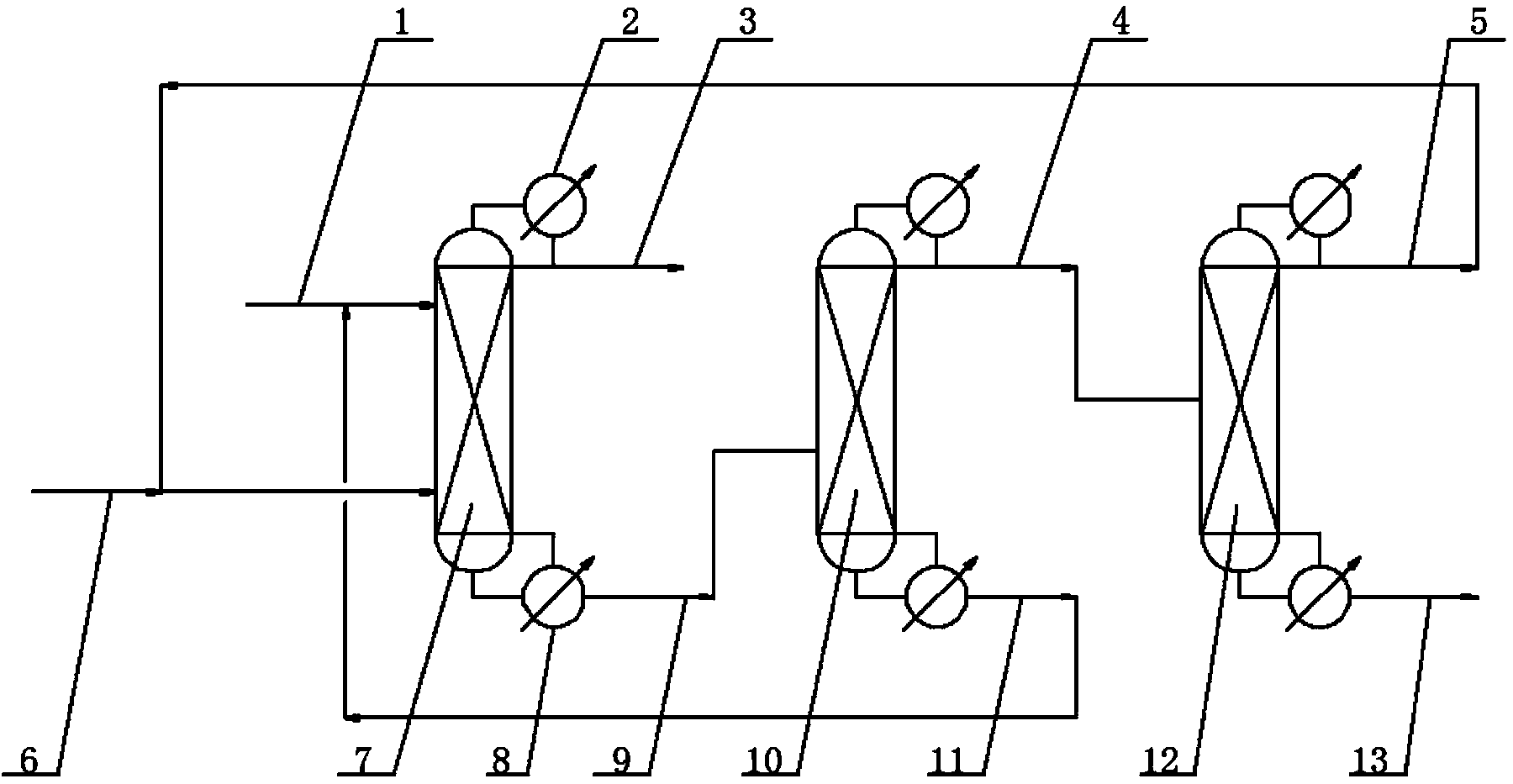

[0030] Such as figure 1 The new energy-saving three-tower continuous extraction and rectification system for alcohol is shown. The energy-saving three-tower continuous extraction and distillation system is sequentially connected by an extractive distillation system, a solvent recovery system and an azeotropic distillation system.

[0031] The extractive distillation system comprises an extractive distillation tower 7, the upper end of the extractive distillation tower 7 is connected to the condenser 2, the condenser 2 is connected back to the extractive distillation tower 7 through a pipeline, and the lower end of the extractive distillation tower 7 is connected to a reboiler through a pipeline 8. The reboiler 8 is connected back to the extractive distillation tower 7 through a pipeline; the raw material azeotrope inlet pipe 6 is arranged on the lower side of the extractive distillation tower 7, and the extraction agent inlet pipe 1 is arranged on the upper side;

[0032] The ...

Embodiment 2

[0042] The new energy-saving three-tower continuous extraction rectification alcohol system used in this example is the same as that in Example 1.

[0043] The extractive distillation column 7 has 25 plates, and the azeotrope system 6 (ethanol-water azeotrope system with 70% ethanol mass percentage) that has been preheated to 78°C enters the tower body from the 22nd plate, and the feed flow The rate is 100mol / h, and the extraction agent 1 (ethylene glycol) that has been preheated to 20°C enters the tower body from the seventh plate, the feed flow rate is 100mol / h, and 1000mL of material enters the bottom of the tower, and after 1 hour of total reflux Operation, the set reflux ratio is 0.1, the top pressure is maintained at 1 atm, the extraction flow rate at the top of the tower is 70mol / h, the extraction of high purity 3 (ethanol concentration is 99.98%), and the extraction flow rate at the bottom of the tower is 25mol / h , the produced liquid enters the extraction agent recove...

Embodiment 3

[0045] The new energy-saving three-tower continuous extraction rectification alcohol system used in this example is the same as that in Example 1.

[0046] The extractive distillation tower 7 has 25 plates, and the azeotrope system 6 (ethanol-water azeotrope system with 60% ethanol mass percentage) that has been preheated to 78°C enters the tower body from the 22nd plate, and the feed flow The rate is 100mol / h, and the extraction agent 1 (ethylene glycol) that has been preheated to 20°C enters the tower body from the seventh plate, the feed flow rate is 100mol / h, and 1000mL of material enters the bottom of the tower, and after 1 hour of total reflux Operation, the set reflux ratio is 0.1, the top pressure is maintained at 1 atm, the extraction flow rate at the top of the tower is 70mol / h, the extraction of high purity 3 (ethanol concentration is 99.00%), and the extraction flow rate at the bottom of the tower is 25mol / h , the produced liquid enters the extraction agent recover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com