Method for preparing carboxymethyl inulin under promotion of ionic liquid

A technology of carboxymethyl inulin and ionic liquid, applied in the chemical industry, can solve the problems such as unsatisfactory degree of substitution and yield of carboxymethyl inulin, inability to expand production by synthesis process, influence of carboxymethylation of inulin, and the like. Excellent appearance, promotion of alkalization and etherification reactions, and high degree of substitution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

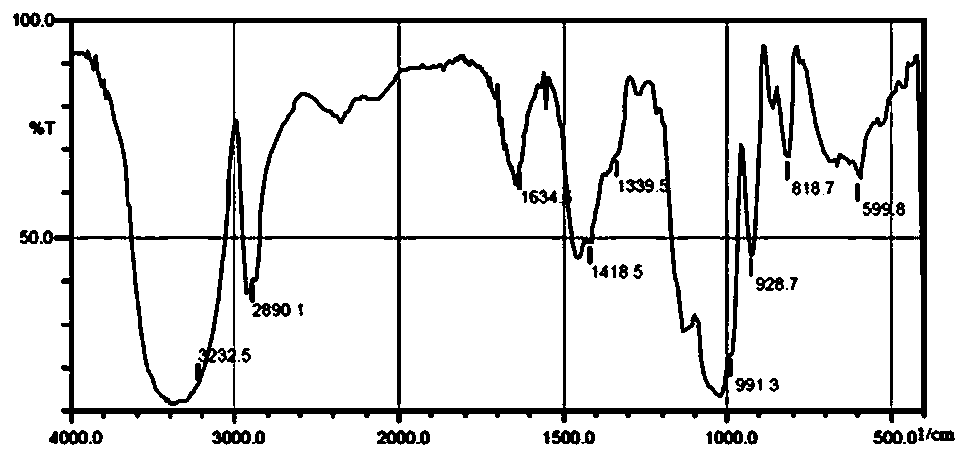

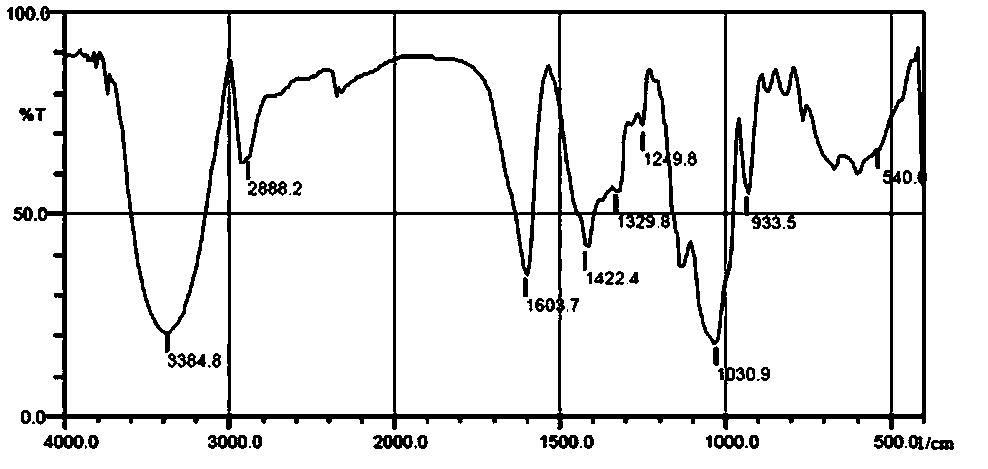

Image

Examples

Embodiment 1

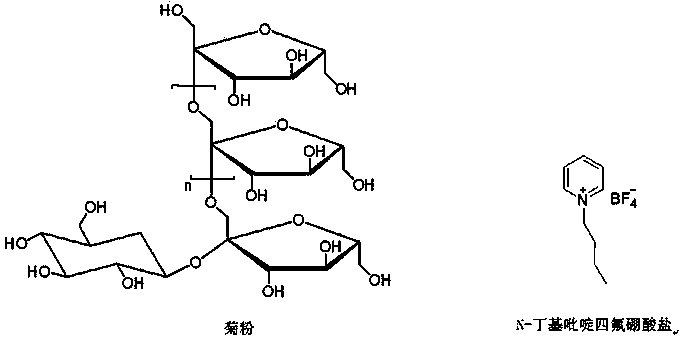

[0019] In this embodiment, a method for preparing carboxymethyl inulin under the promotion of ionic liquid is obtained by taking 56 g of inulin, 29 g of chloroacetic acid, 22 g of sodium hydroxide, and 1 g of N-butylpyridine tetrafluoroborate, and preparing it according to the following steps:

[0020] 1) Put 56g of inulin, 1g of N-butylpyridine tetrafluoroborate and 11g of sodium hydroxide into the round-bottomed flask filled with 284ml of ethanol according to the above parts by weight;

[0021] 2) After stirring at a room temperature of 20°C for 10 minutes, add the remaining 11 g of sodium hydroxide to prepare alkalized inulin for later use;

[0022] 3) Dissolve 29 g of chloroacetic acid in an appropriate amount of ethanol, add the obtained chloroacetic acid alcohol solution dropwise to the alkalized inulin prepared in step 2), and then react at room temperature for 1.5 h;

[0023] 4) The reactant prepared in step 3) was left to stand for 5 minutes, and suction filtered acc...

Embodiment 2

[0026] In this embodiment, a method for preparing carboxymethyl inulin under the promotion of ionic liquid is obtained by taking 112 g of inulin, 58 g of chloroacetic acid, 44 g of sodium hydroxide, and 2 g of N-butylpyridine tetrafluoroborate, and preparing it according to the following steps:

[0027] 1) Put 112g of inulin, 2g of N-butylpyridine tetrafluoroborate and 22g of sodium hydroxide into the round-bottomed flask filled with 856ml of isopropanol according to the above parts by weight;

[0028] 2) After stirring at a room temperature of 30°C for 15 minutes, add the remaining 22 g of sodium hydroxide to prepare alkalized inulin for later use;

[0029] 3) The chloroacetic acid of the above ratio is dissolved in an appropriate amount of isopropanol, and the obtained chloroacetic acid alcohol solution is added dropwise to the alkalized inulin prepared in step 2), and then at room temperature at 30 Reaction at ℃ for 2h;

[0030] 4) The reactant prepared in step 3) was left...

Embodiment 3

[0033] The preparation method of a kind of ionic liquid carboxymethyl inulin in this embodiment, take inulin 84g, chloroacetic acid 43.5g, sodium hydroxide 16.5g, N-butylpyridine tetrafluoroborate 1.5g, make according to the following steps :

[0034] 1) Put 84g of inulin, 1.5g of N-butylpyridine tetrafluoroborate and 8.25g of sodium hydroxide into the round-bottomed flask filled with 535ml of isopropanol according to the above parts by weight;

[0035] 2) After stirring at a room temperature of 25°C for 13 minutes, add the remaining 8.25 g of sodium hydroxide to prepare alkalized inulin for later use;

[0036] 3) The chloroacetic acid of the above ratio is dissolved in an appropriate amount of isopropanol, and the obtained chloroacetic acid alcohol solution is added dropwise to the alkalized inulin prepared in step 2), and then at room temperature at 25 Reaction at ℃ for 2h;

[0037] 4) The reactant prepared in step 3) was left to stand for 8 minutes, and suction filtered a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com