Preparation method and product of stain-resistant anti-aging wood-plastic material

A wood-plastic material and anti-aging technology, applied in the field of preparation of anti-fouling and anti-aging wood-plastic materials, can solve the problems of low mechanical properties, aging resistance, easy to be contaminated, etc., to improve mechanical properties, not easy to get dirty , the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of the anti-fouling and anti-aging wood-plastic material provided in this embodiment comprises the following steps:

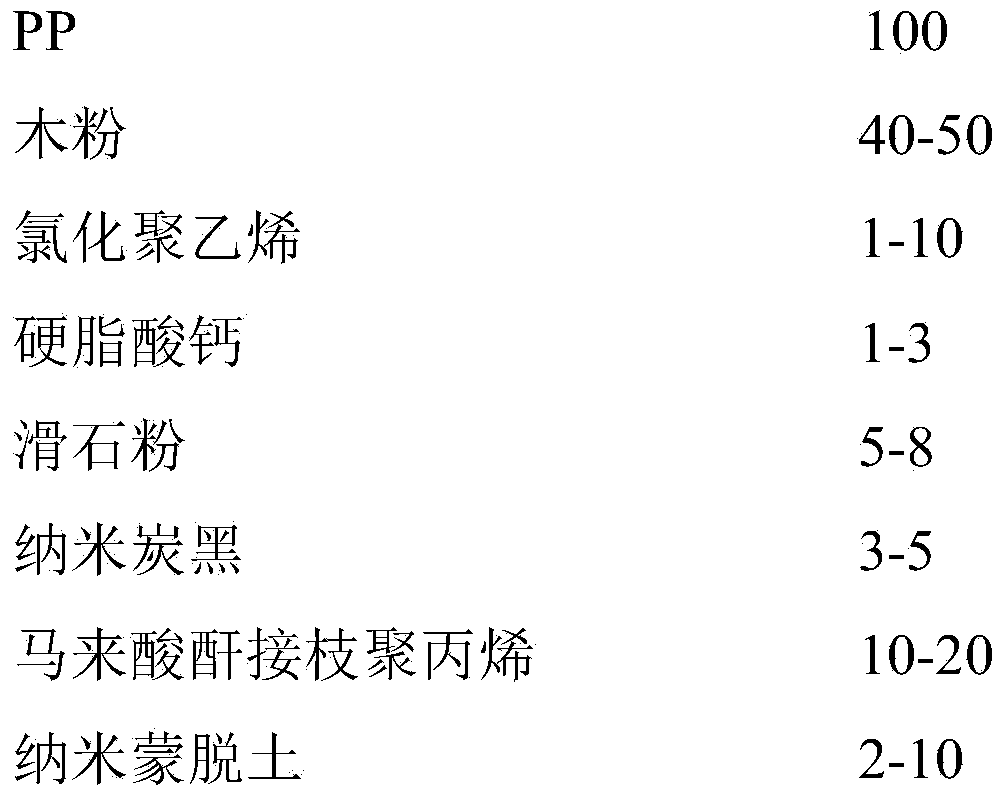

[0031] 1) Prepare the following components in parts by weight:

[0032]

[0033] Wherein, the nano-modified montmorillonite is prepared through the following steps:

[0034] 1.1) Weigh 4-6 parts by weight of montmorillonite and disperse it in 150-200 parts by weight of deionized water, and keep the temperature at 70-90°C for 20-40min;

[0035] 1.2) Weigh 1-3 parts by weight of CTAB, that is, cetyltrimethylammonium bromide, place it in deionized water with 20-40 parts by weight, and stir until clarification at 30-40°C;

[0036] 1.3) Add the CTAB solution in step 1.2) dropwise to the montmorillonite solution in step 1.1), heat up to 80-100°C, and keep the temperature constant for 2-3h;

[0037] 1.4) suction filter the solution obtained in step 1.3), and wash repeatedly until no precipitation is detected with silver nitrate;

[...

Embodiment 2

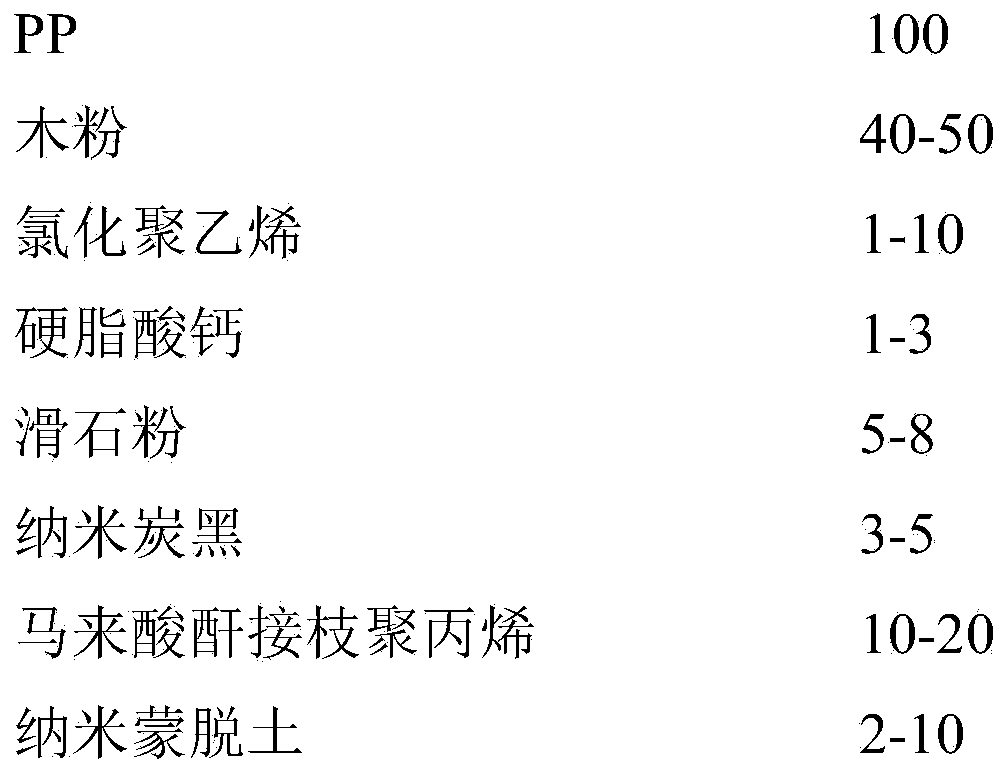

[0048] The preparation method and material of the anti-pollution and aging-resistant wood-plastic material provided in this embodiment are basically the same as those in Example 1, except that it includes the following steps:

[0049] 1) Prepare the following components in parts by weight:

[0050]

[0051]

[0052] Wherein, the nano-modified montmorillonite is prepared through the following steps:

[0053] 1.1) Weigh 4 parts by weight of montmorillonite and disperse it in 150 parts by weight of deionized water, and keep the temperature at 70°C for 20-40min;

[0054] 1.2) Weigh 1 part by weight of CTAB and place it in deionized water with 20 parts by weight, and stir at 30°C until clarified;

[0055] 1.3) Add the CTAB (cetyltrimethylammonium bromide) solution in step 1.2) dropwise to the montmorillonite solution in step 1.1), heat up to 80°C, and keep the temperature constant for 2h;

[0056] 1.4) suction filter the solution obtained in step 1.3), and wash repeatedly u...

Embodiment 3

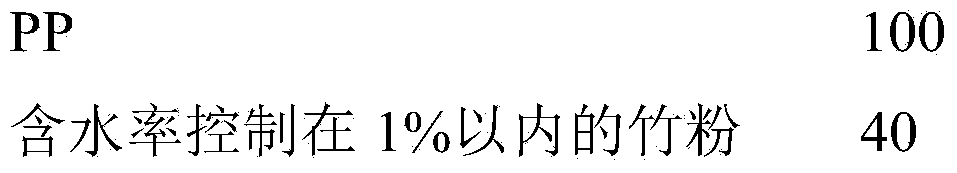

[0061] The preparation method and material of the anti-fouling and aging-resistant wood-plastic material provided in this example are basically the same as those in Examples 1 and 2, except that it includes the following steps:

[0062] 1) Prepare the following components in parts by weight:

[0063]

[0064]

[0065] Wherein, the nano-modified montmorillonite is prepared through the following steps:

[0066] 1.1) Weigh 6 parts by weight of montmorillonite and disperse it in 200 parts by weight of deionized water, and keep the temperature at 90°C for 40 minutes;

[0067] 1.2) Weigh 3 parts by weight of CTAB and place it in deionized water with 40 parts by weight, and stir at 40°C until clarified;

[0068] 1.3) Add the CTAB (cetyltrimethylammonium bromide) solution in step 1.2) dropwise to the montmorillonite solution in step 1.1), and raise the temperature to 100° C., and keep the temperature for 3 hours;

[0069] 1.4) suction filter the solution obtained in step 1.3),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com