Microemulsion flooding composition for oil field

A technology of microemulsion and composition, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of difficult determination of oil displacement effect, heating oil displacement agent, oil layer damage, etc. The effect of reducing water content and increasing crude oil production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The surfactant composition that is used for microemulsion flooding, its component and content are:

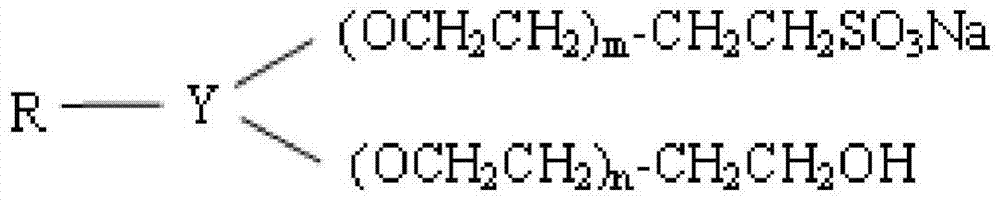

[0034] (A) 30wt% anion-nonionic surfactant with following molecular structure:

[0035]

[0036] Wherein, R is an lipophilic group, which is a carbon chain with 12 carbons, and the carbon chain does not contain double bonds;

[0037] Y is a diphenyl ether group;

[0038] (OCH 2 CH 2 ) m and (OCH 2 CH 2 ) n Is a polyoxyethylene ether chain link, m=5, n=5;

[0039] -SO 3 Na is a sodium sulfonate group, and one of the two polyoxyethylene ether chain links is connected with a sodium sulfonate group;

[0040] (B) 20wt% alkyl alcohol polyoxyethylene ether;

[0041] (C) 10wt% ethanol;

[0042] (D) 20-50wt% tap water.

[0043] The above components are mixed and stirred evenly at normal temperature and pressure to make a water-soluble liquid.

Embodiment 2

[0045] The surfactant composition that is used for microemulsion flooding, its component and content are:

[0046]

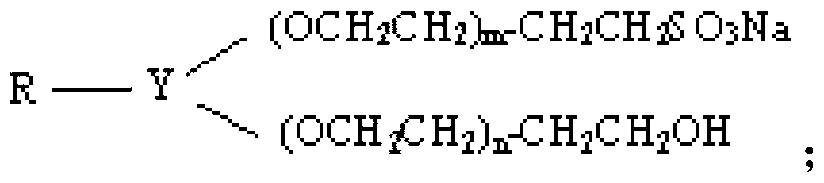

[0047] (A) 25wt% anion-nonionic surfactant with following molecular structure:

[0048] Wherein, R is an lipophilic group, which is a carbon chain with 18 carbons, and the carbon chain does not contain double bonds;

[0049] Y is a benzene ring group;

[0050] (OCH 2 CH 2 ) m and (OCH 2 CH 2 ) n Is a polyoxyethylene ether chain link, m=5, n=5;

[0051] SO 3 Na is a sodium sulfonate group, and one of the two polyoxyethylene ether chain links is connected with a sodium sulfonate group;

[0052] (B) 25wt% alkylphenol polyoxyethylene ether;

[0053] (C) 15wt% ethanol;

[0054] (D) 35 wt% tap water.

[0055] The above components are mixed and stirred evenly at normal temperature and pressure to make a water-soluble liquid.

Embodiment 3

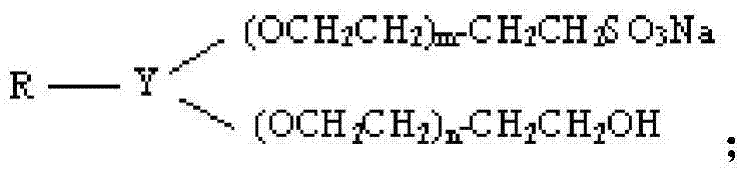

[0057] (A) 20wt% anion-nonionic surfactant with following molecular structure:

[0058]

[0059] Wherein, R is an lipophilic group, which is a carbon chain with 18 carbons, and the carbon chain does not contain double bonds;

[0060] Y is a benzene ring group;

[0061] (OCH 2 CH 2 ) m and (OCH 2 CH 2 ) n It is a polyoxyethylene ether chain link, m=5, n=10;

[0062] SO 3 Na is a sodium sulfonate group, and one of the two polyoxyethylene ether chain links is connected with a sodium sulfonate group;

[0063] (B) castor oil polyoxyethylene ether of 30wt%;

[0064] (C) 15wt% ethanol;

[0065] (D) 35 wt% tap water.

[0066] The product is obtained after mixing the above components evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com