Block copolymer emulsification enhancement combination flooding composition and application thereof

A technology of block copolymer and compound flooding, which is applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problem that crude oil cannot be extracted, and achieve the goal of increasing microscopic swept volume, improving oil displacement efficiency and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

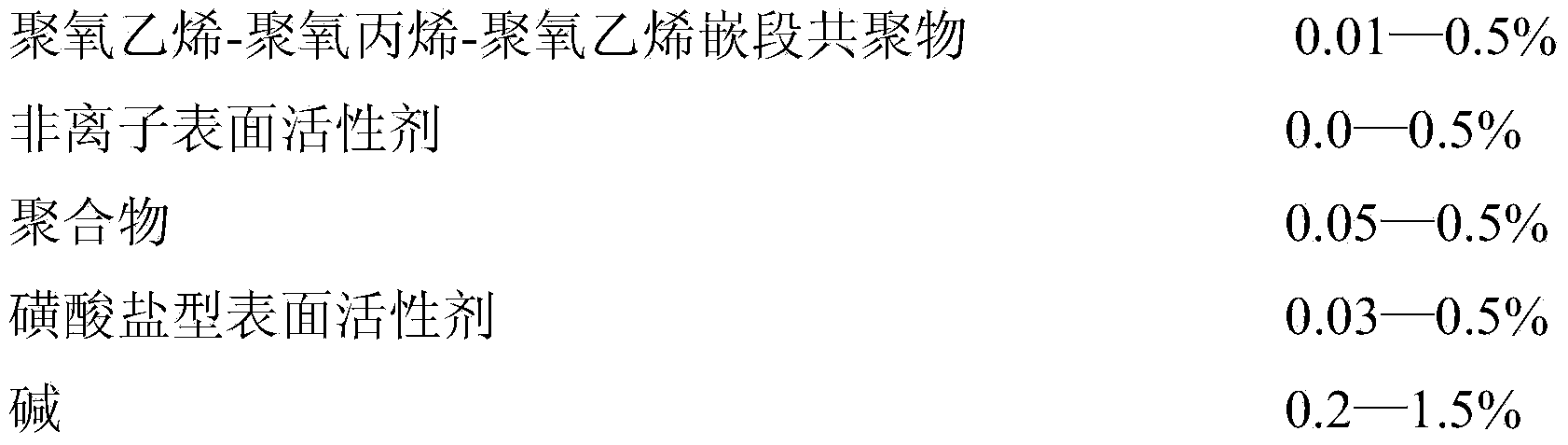

[0036] Enhanced emulsified composite flooding composition:

[0037] (1) Polyoxyethylene-polyoxypropylene-polyoxyethylene block copolymer: ethylene oxide (122) propylene oxide (47) oxyethylene (122) block copolymer ( F98) (purchased by BASF Corporation).

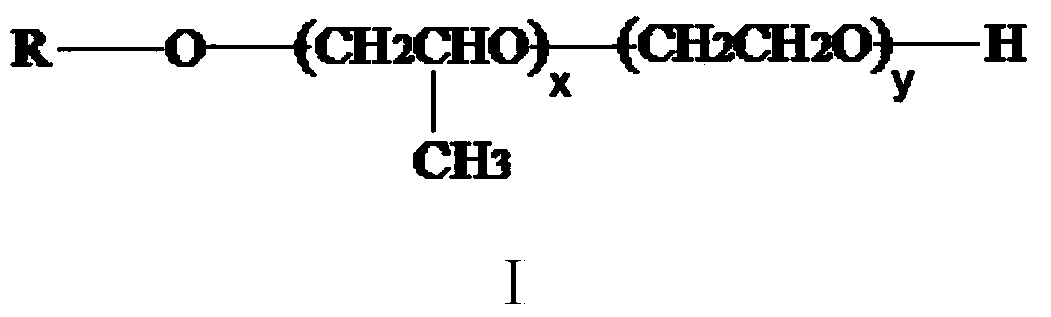

[0038] (2) Nonionic surfactant: stearyl alcohol polyoxypropylene (5) polyoxyethylene (20) ether (provided by Tianjin University of Technology).

[0039] (3) Polymer: The water-soluble polymer is partially hydrolyzed polyacrylamide HPAM, produced by Daqing Refining and Chemical Company, with a molecular weight of 25 million.

[0040] (4) Sulfonate-type surfactant: Heavy alkylbenzene sulfonate is produced by Daqing Donghao Investment Co., Ltd.

[0041] Composition of enhanced emulsified composite flooding composition:

[0042]

[0043] The rest is water.

[0044] Enhanced emulsion composite flooding composition Bailey core flooding experiment:

[0045] The Bailey core flooding experiment was carried out in accordance w...

Embodiment 2

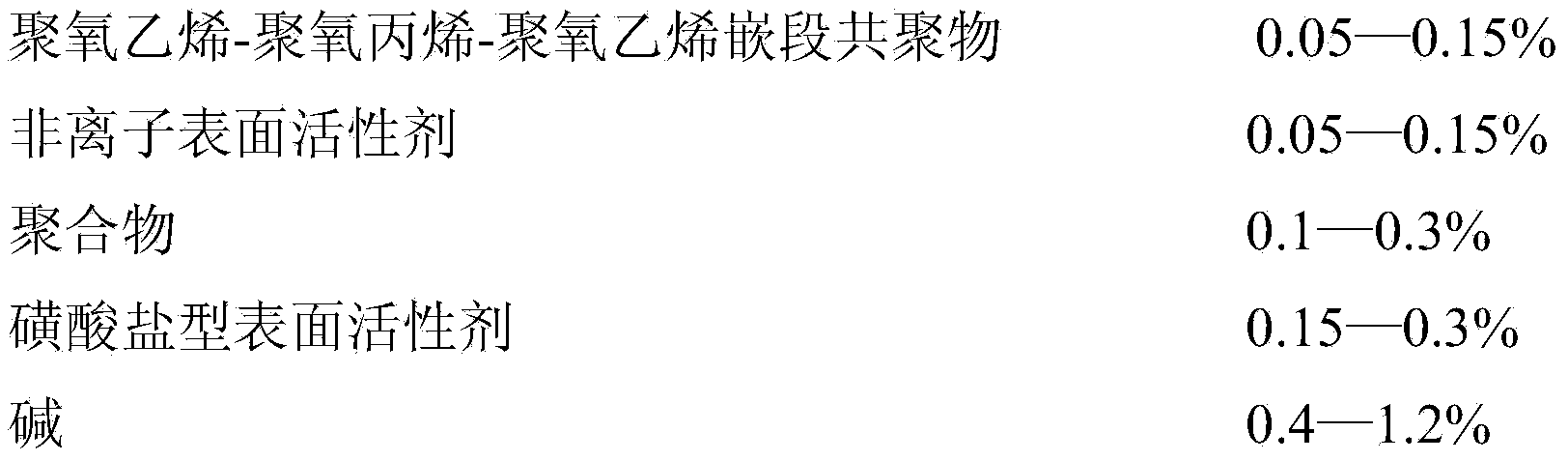

[0053] Composition of enhanced emulsified composite flooding composition:

[0054]

[0055]

[0056] The rest is water.

[0057] Enhanced emulsion composite flooding composition Bailey core flooding experiment:

[0058] The Bailey core flooding experiment was carried out in accordance with the Petroleum and Natural Gas Industry Standard SY / T6424-2000 of the People's Republic of China. The oil used in the experiment was simulated oil from Daqing No. 1 Plant, and the water used in the experiment was simulated water from Daqing No. 1 Plant. When the water flooding reaches 100% water cut, inject 0.7 times the pore volume (PV) of the enhanced emulsified composite flooding composition, and then carry out water flooding until the water cut reaches 100%.

[0059] The parameters of the Bailey core are shown in Table 3.

[0060] Table 3. Bailey core parameters for the composition experiment of Example 2

[0061]

[0062] The enhanced emulsified composite flooding compositio...

Embodiment 3

[0066] Composition of enhanced emulsified composite flooding composition:

[0067]

[0068] The rest is water.

[0069] Enhanced emulsion composite flooding composition Bailey core flooding experiment:

[0070] The Bailey core flooding experiment was carried out in accordance with the Petroleum and Natural Gas Industry Standard SY / T6424-2000 of the People's Republic of China. The oil used in the experiment was simulated oil from Daqing No. 1 Plant, and the water used in the experiment was simulated water from Daqing No. 1 Plant. When the water flooding reaches 100% water cut, inject 0.7 times the pore volume (PV) of the enhanced emulsified composite flooding composition, and then carry out water flooding until the water cut reaches 100%.

[0071] The parameters of the Bailey core are shown in Table 5.

[0072] Table 5. Bailey core parameters for the composition experiment of Example 3

[0073]

[0074] The enhanced emulsified composite flooding composition of Example...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com