Vegetable insulating oil treating full-set process

A plant insulating oil and vegetable oil technology, which is applied in the direction of fat oil/fat refining and fat generation, can solve the problems of high dielectric loss requirements, high acid value, and complicated filtering procedures of insulating oil, and achieve the effect of improving electrical performance parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

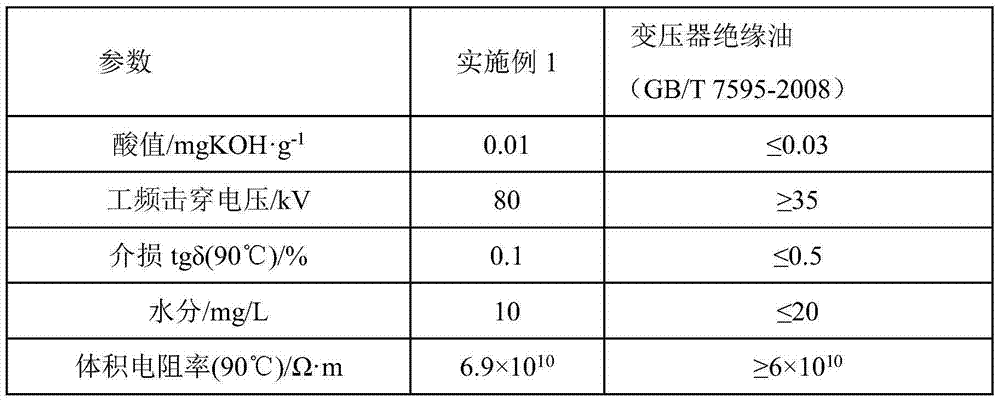

Embodiment 1

[0034] Embodiment 1: The environment-friendly insulating oil using vegetable rapeseed oil as raw material of the present invention can be prepared by the following method, and the complete process for processing the vegetable insulating oil includes the following steps:

[0035] (1) Pump the four-grade rapeseed oil into the primary alkali training pot, raise the temperature of the vegetable oil to 70°C, add NaOH solution at room temperature, stir and mix at a speed of 70r / min for 15min, then stir and mix at a speed of 40r / min for 35min After standing for 11 hours, remove the lower layer of saponins and get the upper layer of oil;

[0036] (2) Heat the oil to 85°C, add ultrapure water with a temperature of 90°C, the quality of ultrapure water is 11% of the oil mass, stir at a speed of 65r / min for 15min, and let stand for 2h to remove the lower layer of wastewater, Take the upper layer of oil.

[0037] (3) repeat (2) twice to remove the saponins in the oil;

[0038] (4) Pump t...

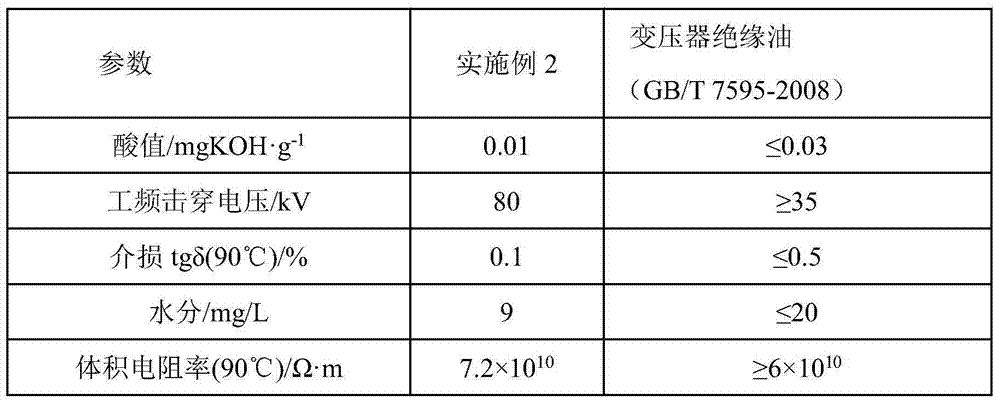

Embodiment 2

[0049] Embodiment 2: The environmental protection insulating oil using vegetable rapeseed oil as raw material of the present invention can be prepared by the following method, and the complete process of processing the vegetable insulating oil includes the following steps:

[0050] (1) Pump the fourth-grade rapeseed oil into the primary alkali training pot, raise the temperature of the vegetable oil to 45°C, add NaOH solution at room temperature, stir and mix at a speed of 75r / min for 10min, then stir and mix at a speed of 35r / min for 40min After standing for 14 hours, remove the lower layer of saponins and get the upper layer of oil;

[0051] (2) Heat the oil to 80°C, add ultra-pure water with a temperature of 95°C, the quality of ultra-pure water is 8% of the oil mass, stir at a speed of 65r / min for 15min, let stand for 2h, remove the lower layer of wastewater, Take the upper layer of oil.

[0052] (3) Repeat (2) twice;

[0053] (4) Pump the oil to the decolorization pot, ...

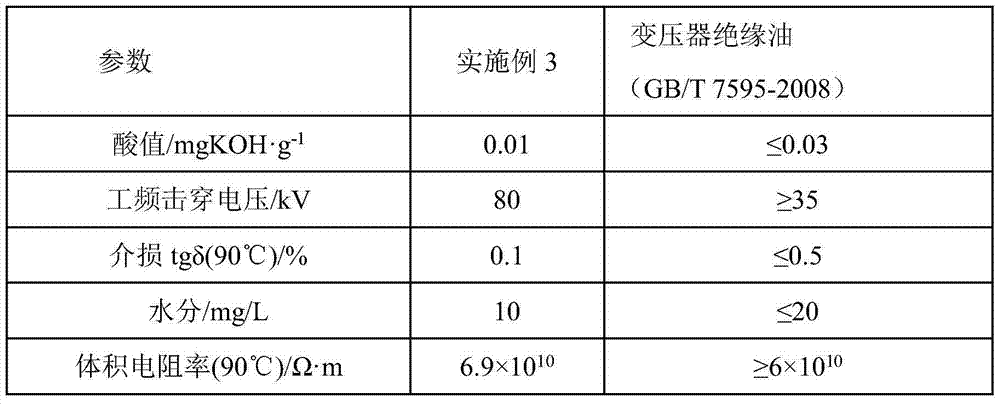

Embodiment 3

[0063] Embodiment 3: The steps are the same as in Embodiment 1, except that the soybean oil used is used to prepare excellent insulating oil.

[0064] The basic parameters of the vegetable insulating oil made in the present embodiment are shown in the table below:

[0065]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com