Preparation method and application of Fe-doped nanotube array membrane

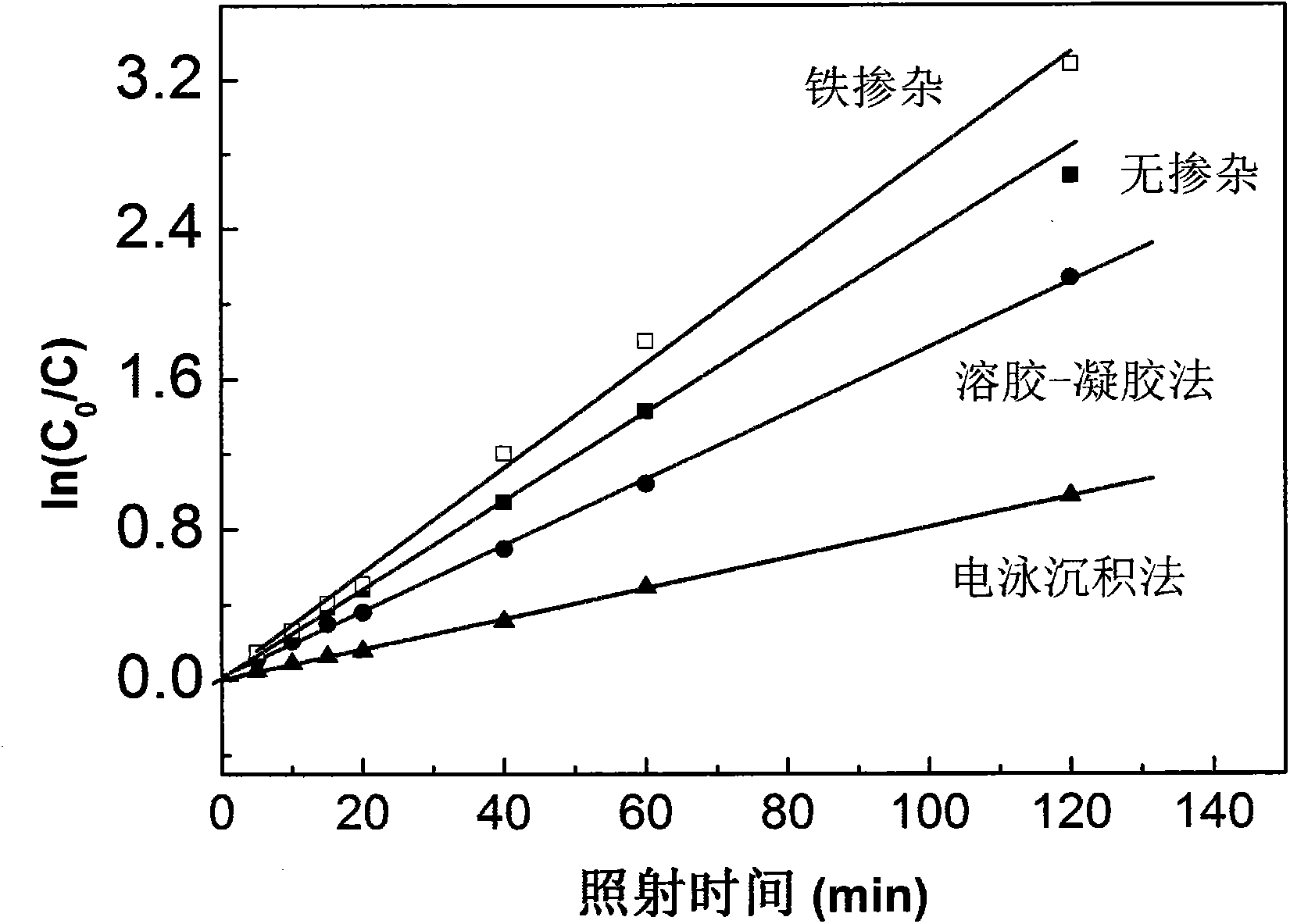

A technology of nanotube array and film layer, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., and can solve the problems of poor doping uniformity of nanotubes and difficult control of doping concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Experimental steps:

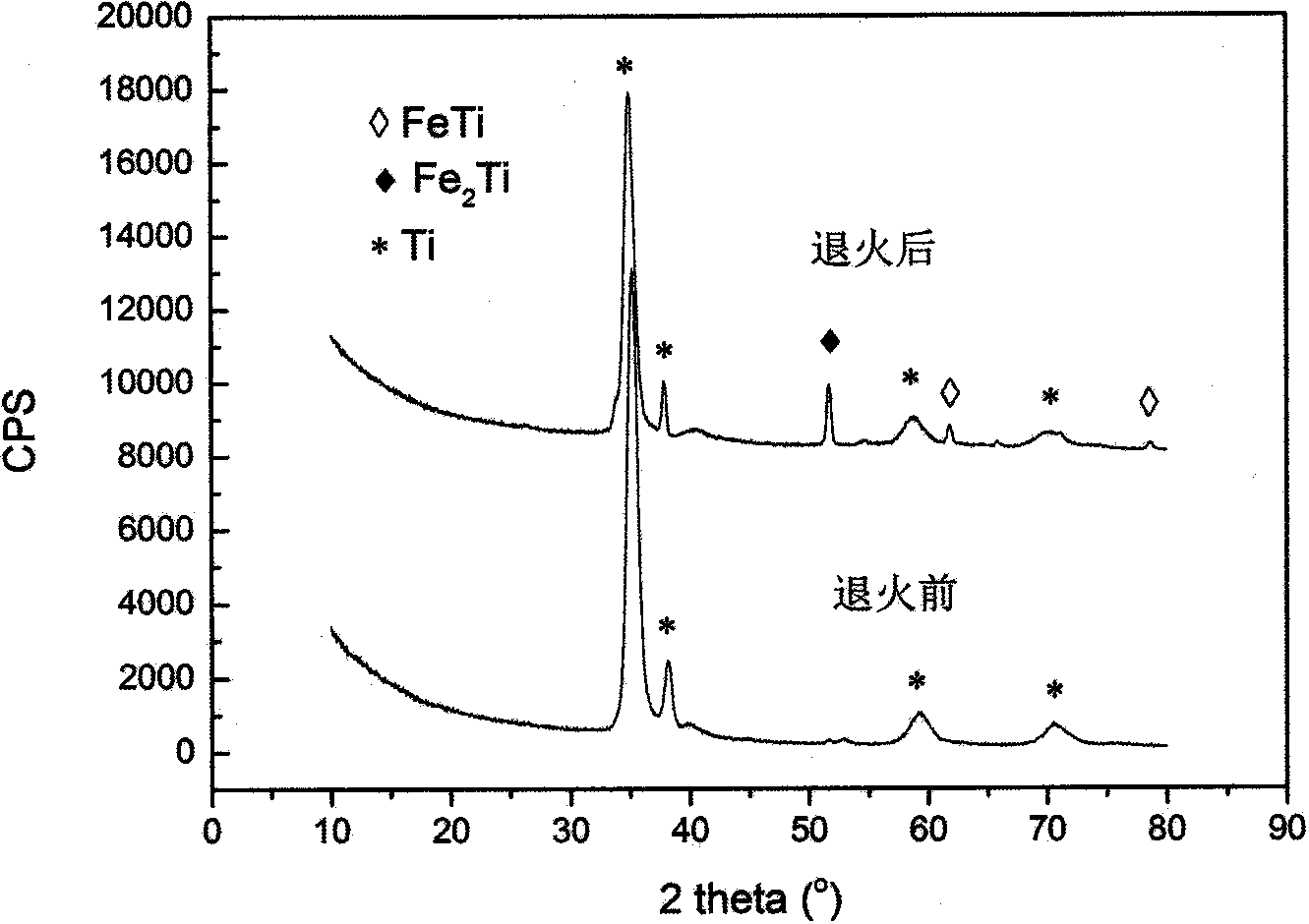

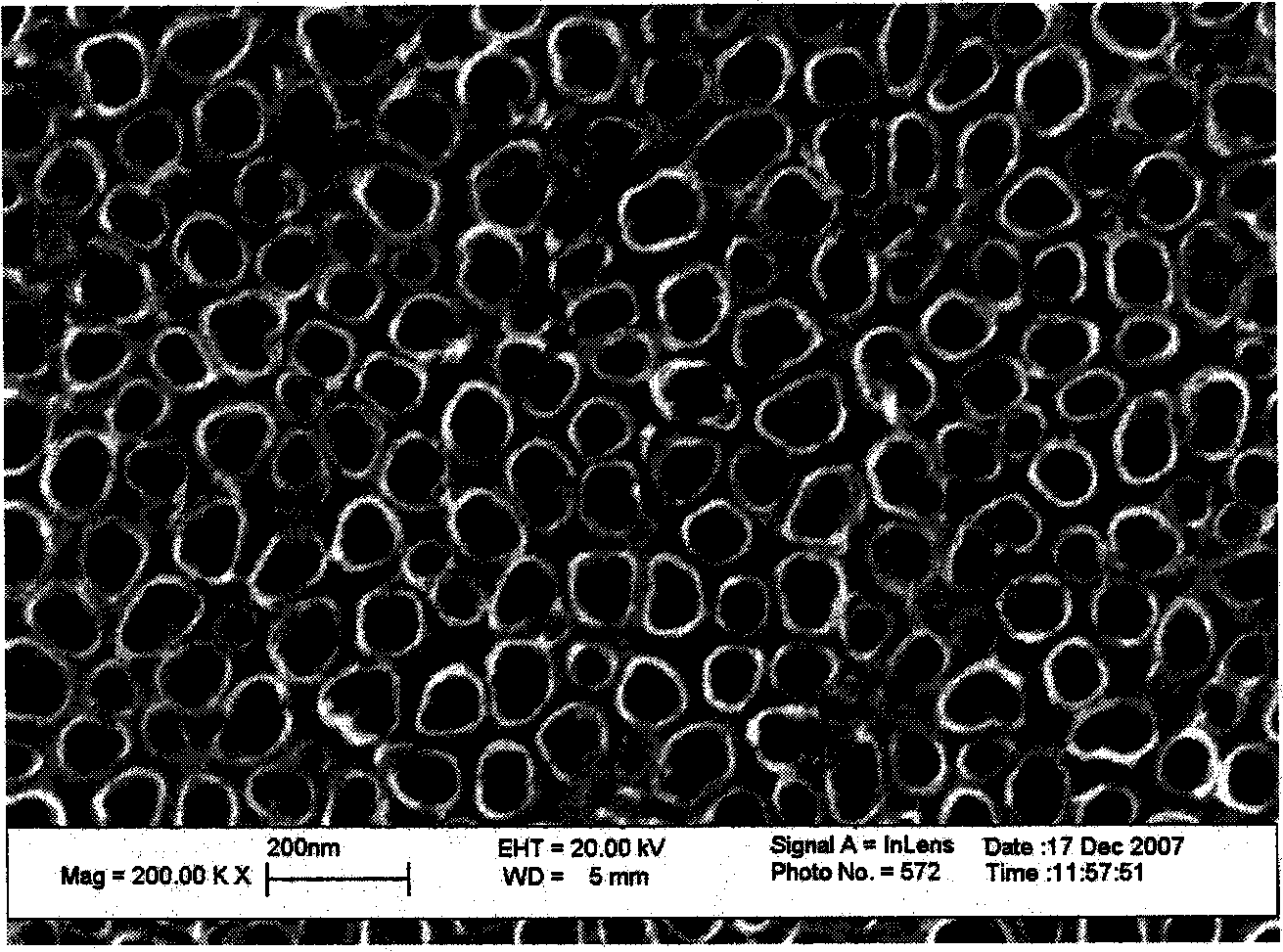

[0020] Fe-doped TiO 2 The nanotube array preparation method is as follows:

[0021] Step 1: Use the JGP450 magnetron sputtering coating machine, which is equipped with 2 radio frequency sputtering targets, in which the sputtering of Ti and Fe films uses 99.999% and 99.99% pure Ti and Fe metal targets, sputtering gas Ar gas; first pump the vacuum chamber to 1×10 -4 Pa, the sputtering pressure is 2-3Pa. The ITO glass substrate was ultrasonically cleaned with acetone, ethanol and secondary deionized water for 15 min. Sputter the Ti film on the ITO glass at room temperature with an Ar flow rate of 8sccm, deposit the Ti film for 2.5 hours with a sputtering power of 100W, then use an excitation power supply of 5A, and sputter an Fe film for 5min at a DC power supply of 0.3A\300V, and then use the Ti film before Deposition conditions The Ti film was deposited for 2.5 hours to obtain an ultra-thin composite film with a sandwich structure of Ti\Fe\Ti. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com