Dipping solution for high-temperature-resistant industrial canvas and preparation method of dipping solution

A dipping liquid and high temperature resistant technology, which is applied in fiber types, textiles and papermaking, fiber treatment, etc., can solve the problems of adhesive layer damage failure, easy to be decomposed, etc., to achieve enhanced adhesive performance, good adhesiveness, The effect of improving the adhesive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The present invention will be further described below in conjunction with embodiment.

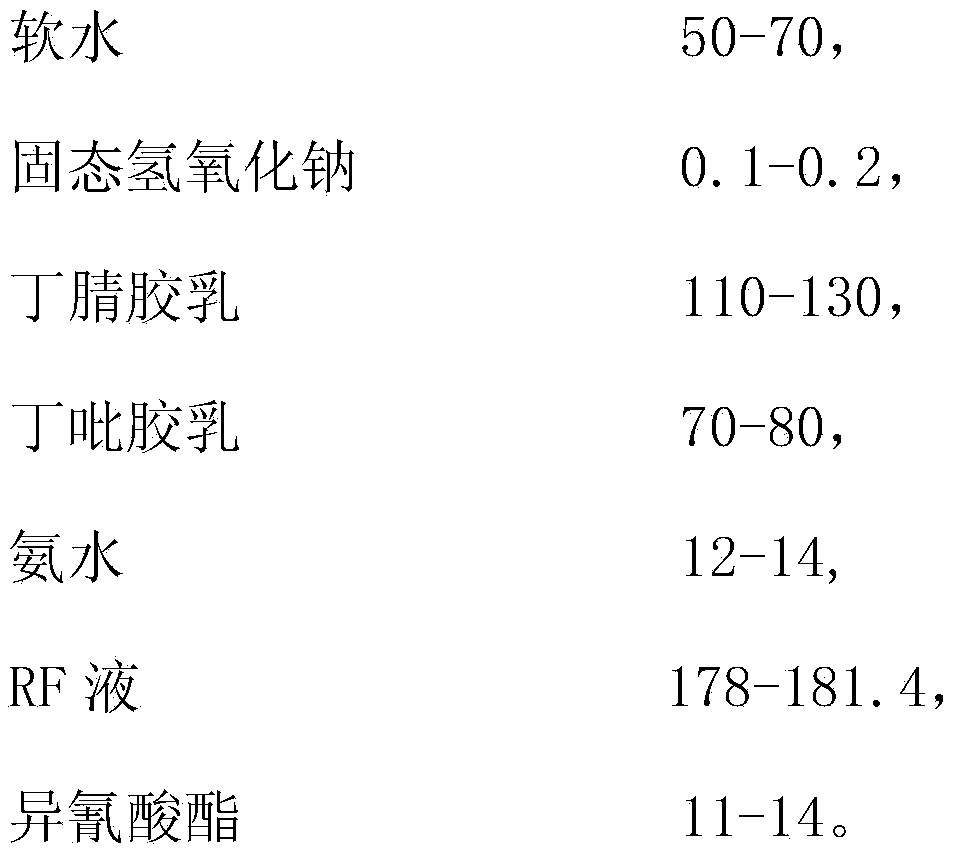

[0024] A dipping solution for high-temperature-resistant industrial canvas, the formula of which includes the following raw materials in parts by weight:

[0025]

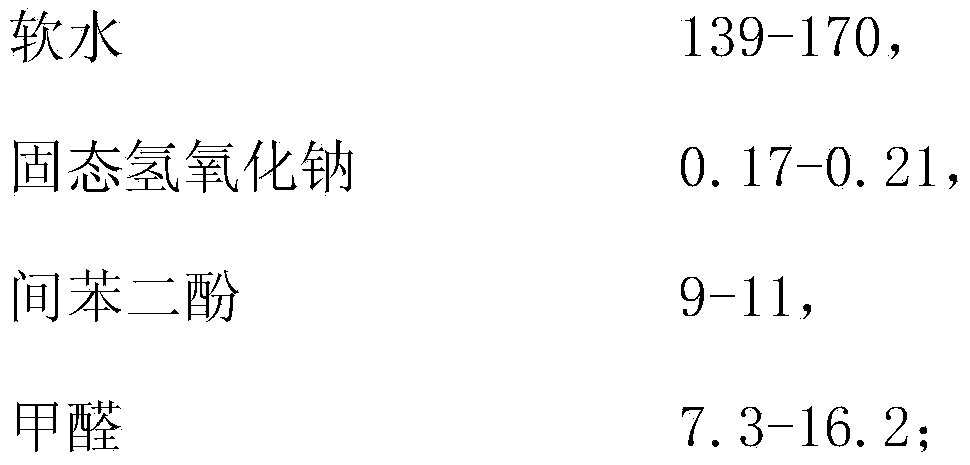

[0026] The formula of described RF liquid comprises the raw material of following weight portion:

[0027]

[0028] The purity of the sodium hydroxide is ≧96%, the mass percent concentration of formaldehyde is 37%, the mass percent concentration of nitrile latex is 45%, the mass percent concentration of butylpyridine latex is 40%, the mass percent concentration of ammonia water Min concentration is 18%.

[0029] A preparation method of a dipping solution for high-temperature-resistant industrial canvas, comprising the following steps:

[0030] (1), according to the formula of the dipping solution, add soft water into the reaction tank, then add sodium hydroxide, mix and stir until dissolved;

[0031] (2), add the...

Embodiment 2

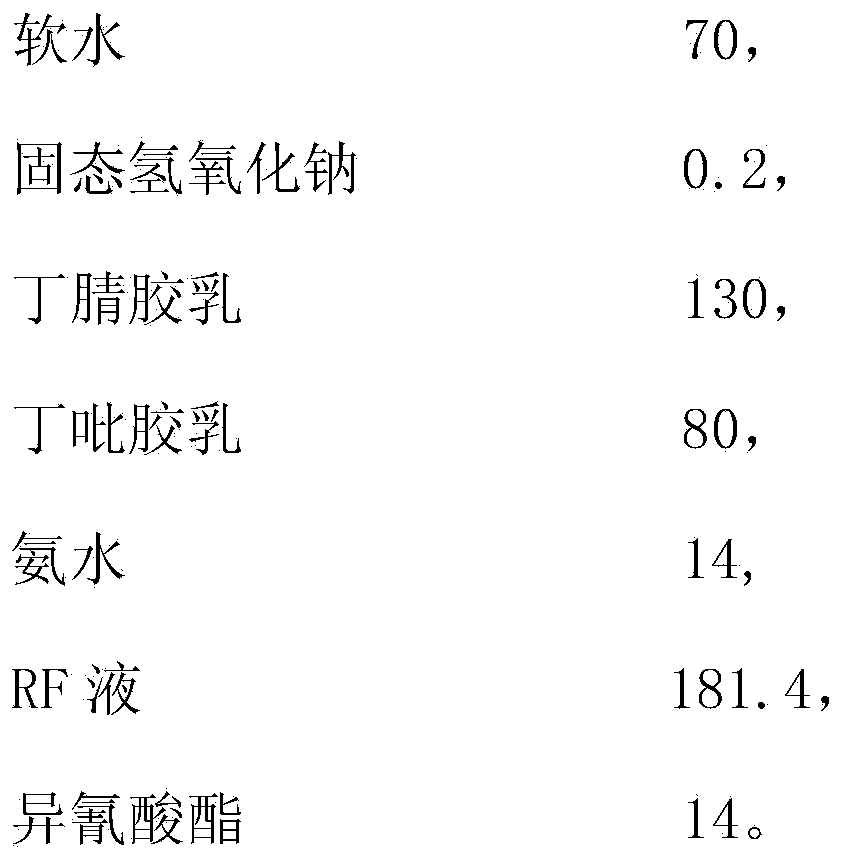

[0040] A dipping solution for high-temperature-resistant industrial canvas, the formula of which includes the following raw materials in parts by weight:

[0041]

[0042] The formula of described RF liquid comprises the raw material of following weight portion:

[0043]

[0044] The purity of described sodium hydroxide is ≥ 96%, the mass percent concentration of formaldehyde is 37.4%, the mass percent concentration of nitrile latex is 40%, the mass percent concentration of butylpyridine latex is 41.5%, the mass percent concentration of ammoniacal liquor Min concentration is 19%.

[0045] A preparation method of a dipping solution for high-temperature-resistant industrial canvas, comprising the following steps:

[0046] (1), according to the formula of the dipping solution, add soft water into the reaction tank, then add sodium hydroxide, mix and stir until dissolved;

[0047] (2), add the nitrile latex and butylpyridine latex of formula quantity again, stir;

[0048]...

Embodiment 3

[0056] A dipping solution for high-temperature-resistant industrial canvas, the formula of which includes the following raw materials in parts by weight:

[0057]

[0058]

[0059] The formula of described RF liquid comprises the raw material of following weight portion:

[0060]

[0061] The purity of described sodium hydroxide is ≥ 96%, the mass percent concentration of formaldehyde is 37%, the mass percent concentration of nitrile latex is 43%, the mass percent concentration of butylpyridine latex is 39.5%, the mass percent concentration of ammoniacal liquor Min concentration is 18%.

[0062] A preparation method and steps of a high-temperature-resistant industrial canvas dipping solution are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com