Film-producing device and method for producing artificial joint composite

A technology for manufacturing devices and artificial joints, which is applied in the direction of hip joints, irradiation devices, joint implants, etc., can solve the problems of not making any disclosures, and achieve the effects of suppressing influence, small heat generation, and accurate control

Active Publication Date: 2014-12-24

KYOCERA CORP

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, Patent Document 1 does not disclose any specific structure for irradiating LEDs to the base material.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

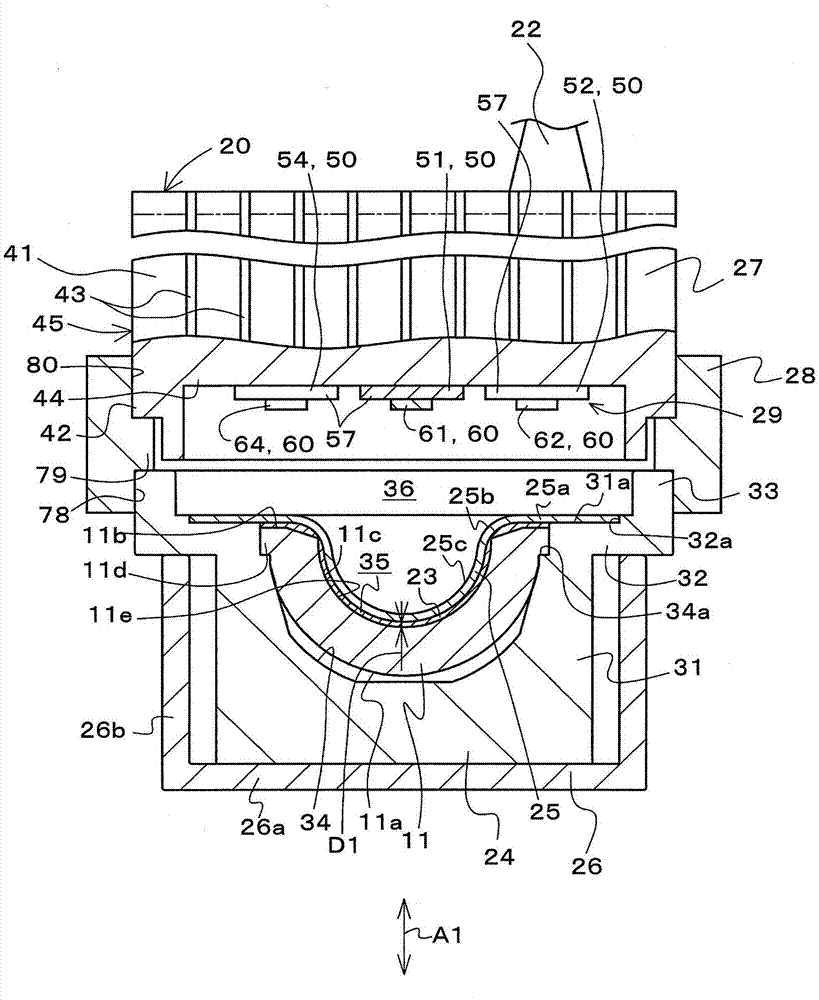

[0052] Hereinafter, modes for implementing the present invention will be described with reference to the drawings. In addition, this invention can be widely used as the manufacturing method of a film manufacturing apparatus and an artificial joint module.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

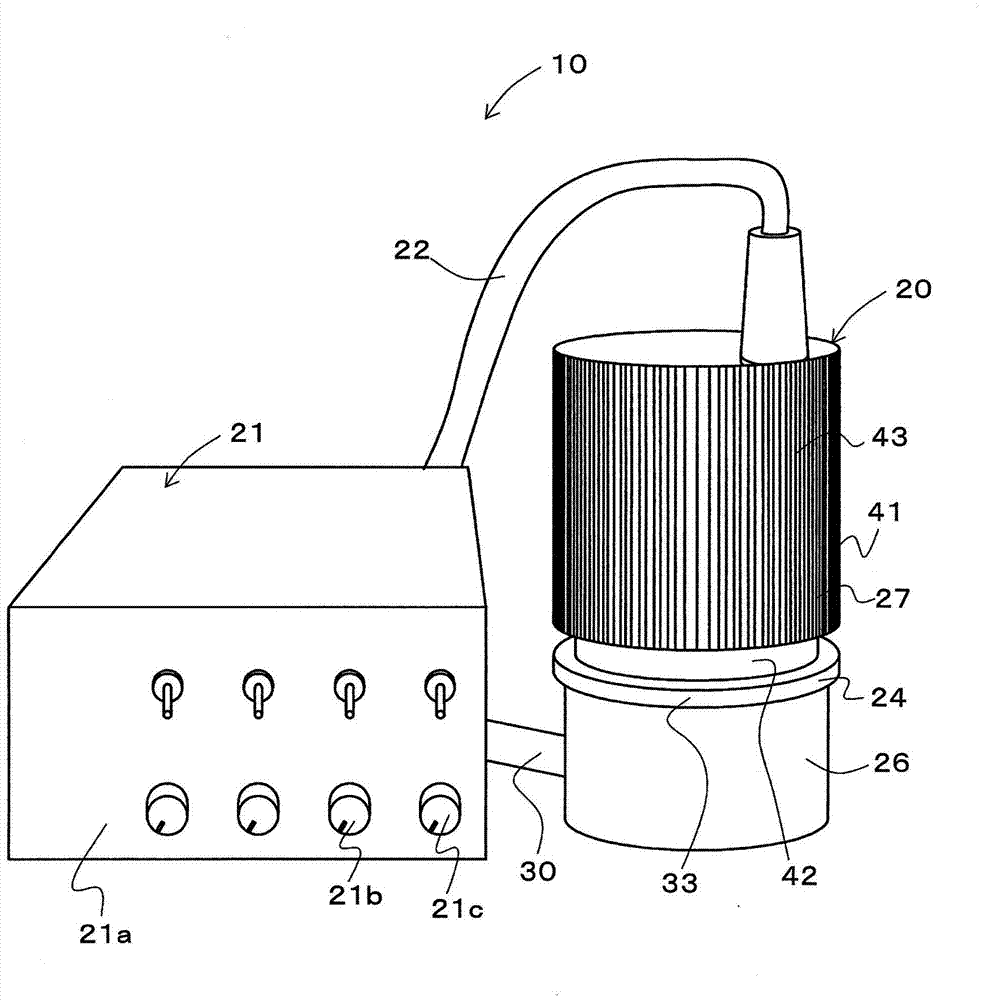

The invention relates to a configuration for forming a polymer layer on a base metal surface of an artificial joint composite. The purpose is successful miniaturization while accurately controlling UV ray irradiation intensity such that a polymer layer of uniform thickness can be formed with no or minimal UV ray effect on workers or facilities. A film-producing device body (20) forms a polymer layer (12) on an inside surface (11e) of a base metal (11) of an artificial joint composite by light-induced graft polymerization. The film-producing device body (20) comprises multiple UV ray LED elements (60) and a work holder (24). A solution (23) containing a polymer monomer is brought into contact with the inside surface 11e of the base metal (11) on the work holder (24). The multiple UV ray LED elements (60) radiate UV rays over a region that is broader than the region irradiated by a single UV ray LED element (60).

Description

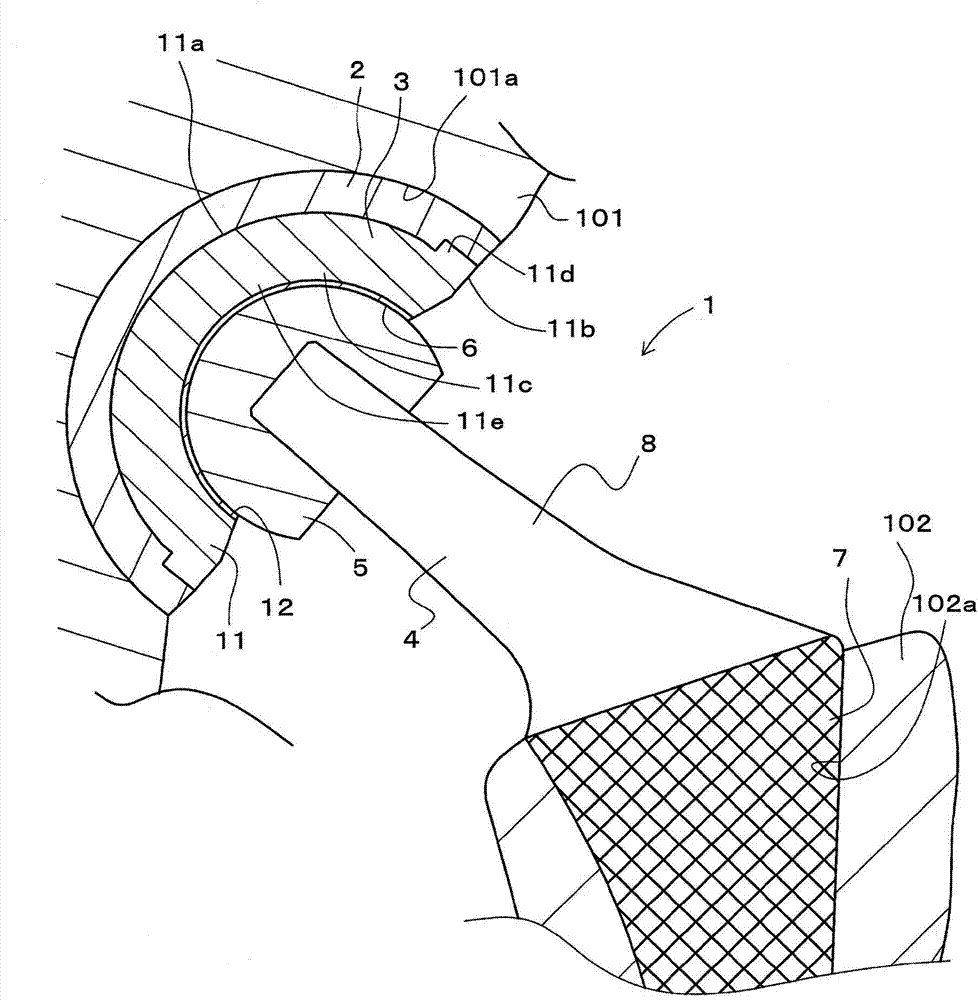

technical field [0001] The present invention relates to a film manufacturing device used for manufacturing an artificial joint unit, and a method for manufacturing an artificial joint unit. Background technique [0002] For the purpose of improving the wear resistance of artificial joints, attempts have been made to form sliding surfaces of artificial joint components with coatings. As a method for forming such a coating layer, a method of forming a polymer layer by photograft polymerization on the surface of a base material which is a main part of an artificial joint component is known (for example, refer to Patent Document 1). [0003] prior art literature [0004] patent documents [0005] Patent Document 1: Japanese Patent Laid-Open No. 2011-197544 (paragraph [0037]) [0006] Patent Document 1 discloses a structure in which a photograft polymerization reaction occurs by irradiating light to a solution of a monomer containing a polymer in a state where the solution is ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A61F2/30C08F2/48

CPCB05D3/067B05D7/22A61F2/30767A61F2/34A61F2/3094A61F2002/30971B05D3/065G21K5/08

Inventor 难波良太

Owner KYOCERA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com