Pressure casting method for purifying, homogenizing, densifying, fine-grained and fine-grained iron and steel slabs

A homogenization and densification technology, applied in the field of die casting, can solve problems such as difficult control of central loose defects, weakened feeding effect, and increased cross-sectional size, so as to promote solidification nucleation, eliminate shrinkage cavity porosity, and reduce Effect of Riser Ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

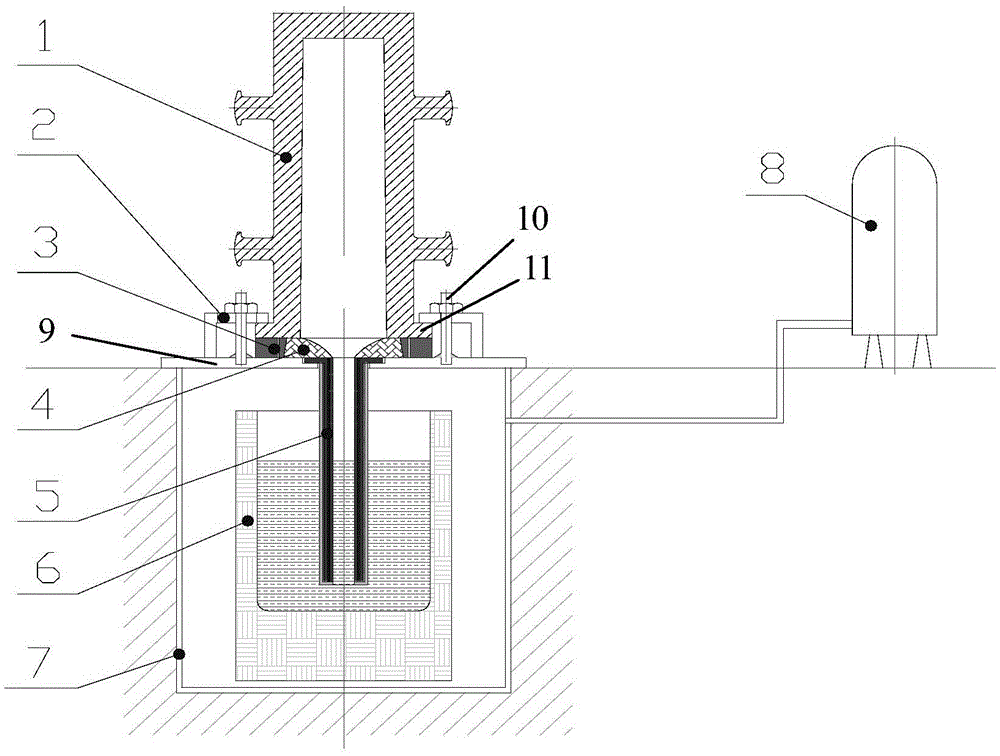

[0056] In this embodiment, the method involved in the present invention is used to prepare a φ800mm×3000mm, 10-ton steel billet, and the material of the molten steel is 45Cr.

[0057] First, electric arc furnace-LF refining and vacuum degassing are used for molten steel treatment, and the weight content of gas and impurity elements is detected before pouring: T.O=15×10 -6 , [S]=40×10 -6 , [P]=80×10 -6 , [H]=1.5×10 -6 , in line with the purity requirements of molten metal.

[0058] Using the pressure casting method of steel slabs, place the molten metal (initial temperature 1550°C, superheat 50°C) into a 15-ton ladle, hoist the ladle into the pressurized tank with tools such as a crane, and then close the pressurized tank top cover. Put the assembled ingot mold cavity and liquid riser into the pressurized casting device, start the pressure controller, and pour the steel billet. By controlling the pressurization method and pressurization speed, the air pressure in the pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com