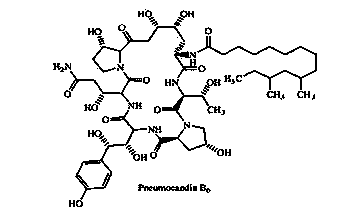

Method for separating and purifying Pneumocandins B0

A technology of separation and purification, pneumocontin, applied in peptide preparation methods, chemical instruments and methods, organic chemistry, etc., can solve the problems of complicated purification process and difficult industrialization of extraction and purification, and achieve high purity, mild separation conditions, The effect of improving the quality of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Take 1000ml of neomocontin B0 fermentation broth, adjust the pH to 4 with oxalic acid, stir for 2 hours, filter, wash the mycelium with 500 ml of water, and collect the mycelium after drying. Take the mycelia, add 1000ml of ethanol solution, soak and stir for 4 hours, filter to obtain about 980ml of extract, concentrate the extract at 50°C to a volume of 100ml; add the mycelium obtained after extraction and filtration to Put into 750ml ethanol solution, soak and stir for 4 hours, filter to obtain about 730ml of extract, concentrate the extract at 50°C to a volume of 75ml, cool to room temperature, combine the two extracts, concentrate at 25°C The ethanol content of the extract to the solution is 25%.

[0031] Take 200ml of AB-8 resin (Cangzhou Baoen Chemical Co., Ltd.) and put it into a resin column (Φ20×500mm), absorb the above-mentioned 25% ethanol content of Neomocontin B0 extract, detect it by HPLC, and then use 400ml Wash the resin column with water, and then wash...

Embodiment 2

[0033] Take 1000ml of neomocontin B0 fermentation broth, adjust the pH to 3 with acetic acid, stir for 1 hour, filter, wash the mycelium with 500 ml of water, and collect the mycelium after drying. Take the mycelium, add 1000ml of methanol solution, soak and stir for 5 hours, filter to obtain about 950ml of extract, concentrate the extract at 50°C to a volume of 100ml; add the mycelium obtained after extraction and filtration to Put into 750ml of methanol solution, soak and stir for 3 hours, filter to obtain about 725ml of extract, concentrate the extract at 50°C to a volume of 72ml, cool to room temperature, combine the two extracts, concentrate at 25°C The methanol content of the leaching liquid to the solution is 20%.

[0034] Take 200ml of HPD-100 resin (Cangzhou Baoen Chemical Co., Ltd.) and put it into a resin column (Φ30×400mm), absorb the above-mentioned Nimocontin B0 extract with a methanol content of 20%, detect it by HPLC, and use it after the adsorption is compl...

Embodiment 3

[0036] Take 1000ml of neomocontin B0 fermentation broth, adjust the pH to 4 with carbonic acid, stir for 2 hours, filter, wash the mycelium with 500 ml of water, and collect the mycelium after drying. Take the mycelium, add 1000ml of acetone solution, soak and stir for 3 hours, filter to obtain about 985ml of extract, concentrate the extract at 50°C to a volume of 100ml; add the mycelium obtained after extraction and filtration to Put into 700ml of acetone solution, stir for 3 hours while soaking, filter to obtain about 735ml of extract solution, concentrate the extract solution at 50°C to a volume of 75ml, cool to room temperature, combine the two extract solutions, and concentrate at 25°C The acetone content of the extract to the solution was 28%.

[0037] Take 200ml of HPD722 resin (Cangzhou Baoen Chemical Co., Ltd.) and put it into a resin column (Φ20×500mm). Adsorb the above-mentioned pneumocidine B0 extract with acetone content of 28%, detect by HPLC, and rinse with 380m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com