Yellow fluorescent powder and preparation method thereof and light emitting device using fluorescent powder

A technology for yellow phosphors and light-emitting devices, applied in the field of yellow phosphors, which can solve the problems of reduced luminous intensity and many surface defects of phosphors, and achieve the effects of reducing production costs, high luminous intensity, and improving luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

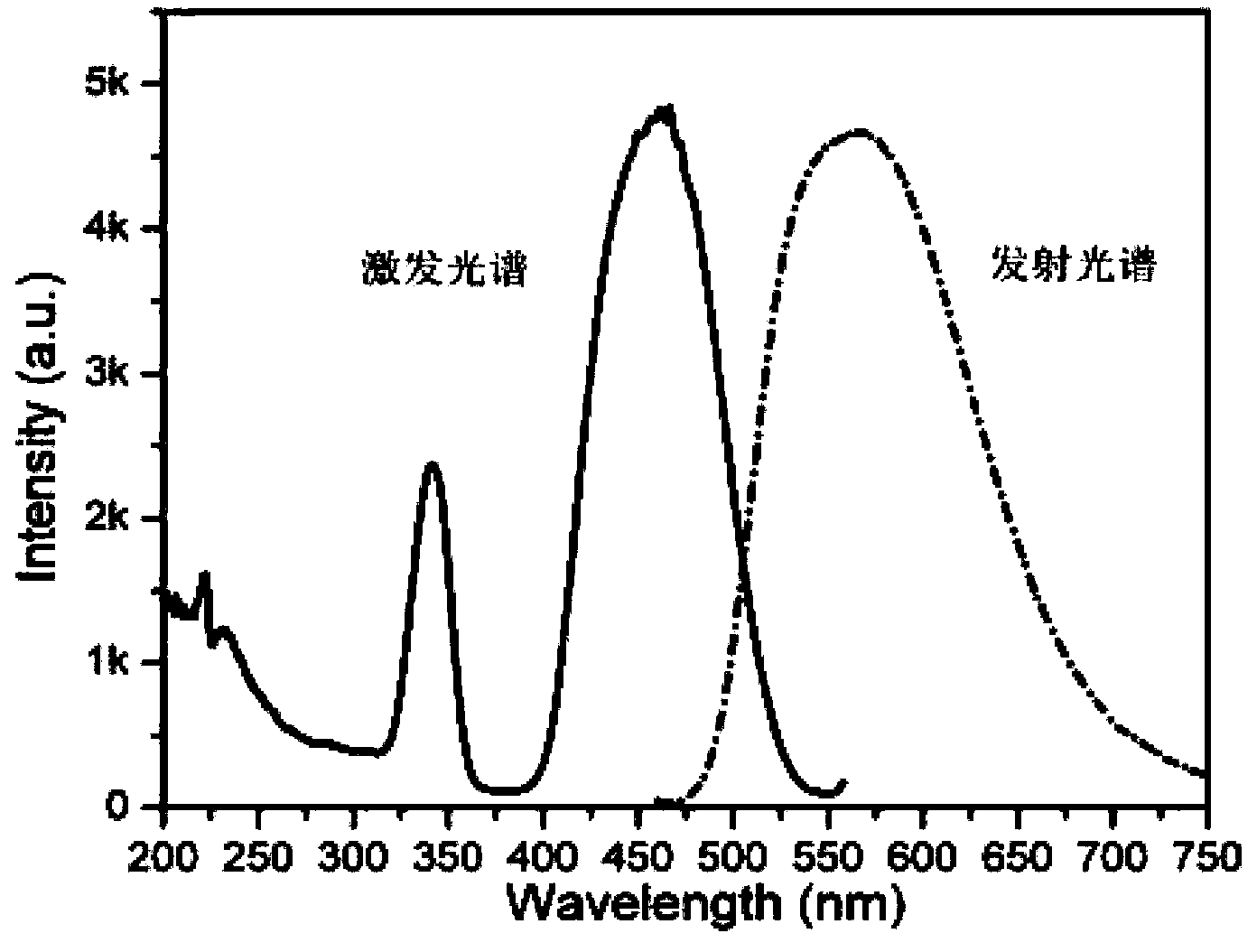

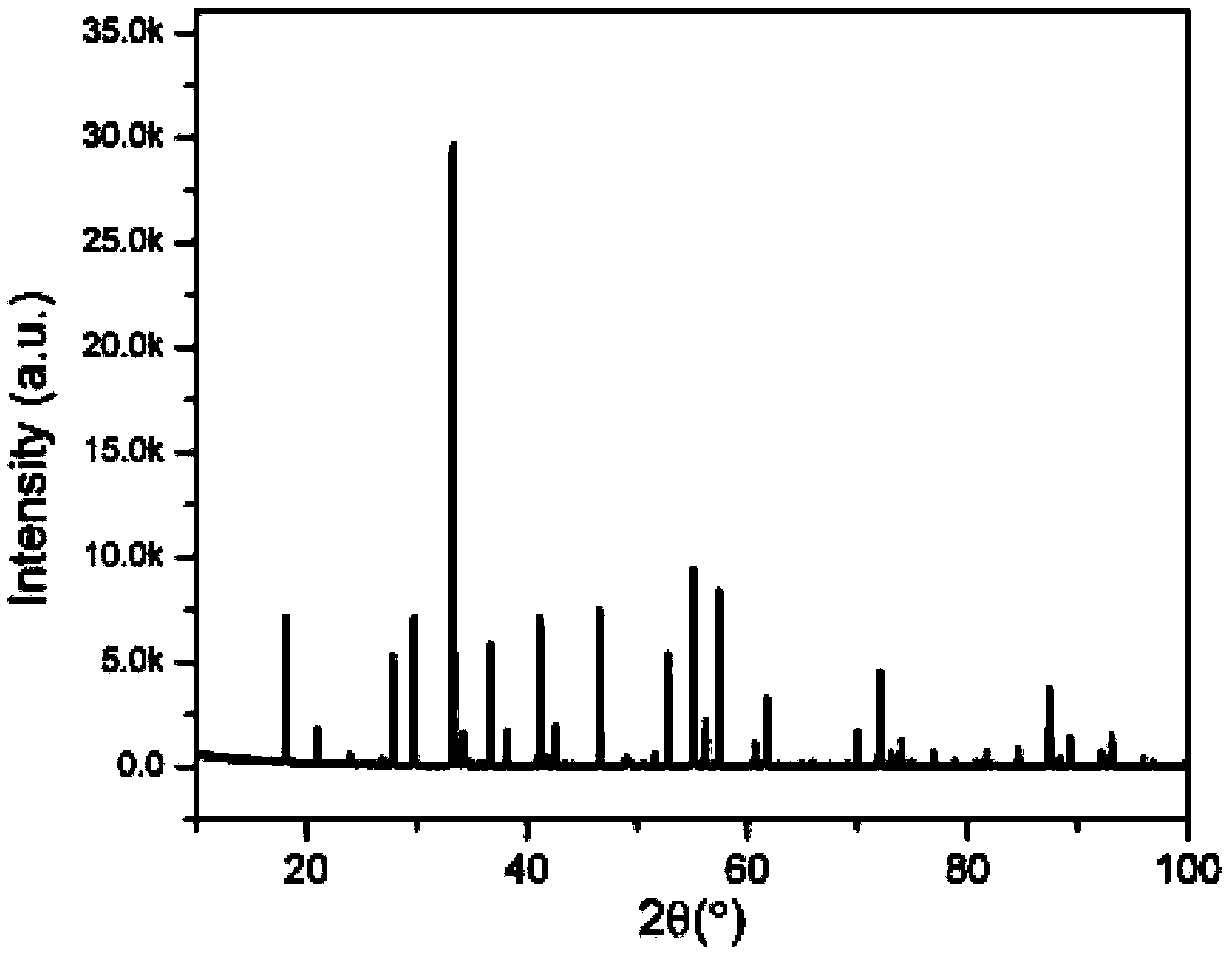

[0048] The chemical formula of embodiment 1 fluorescent powder is Y 2.9 Ce 0.09 Sr 0.01 al 4.99 Si 0.01 o 12

[0049] The raw material is Y 2 o 3 (analytical pure), CeO 2 (analytical pure), SrCO 3 (analytical pure), Al 2 o 3 (analytical pure) and SiO 2 (analytical pure). The molar ratio is 1.45:0.09:0.01:2.495:0.01. Grind and mix the raw materials and place them in an alumina container. Sinter at a temperature of 1550°C for 4 hours. The sintering atmosphere is a mixture of nitrogen and hydrogen. The sintered powder Take it out from the container, choose crushing, grading, and treat it with hydrochloric acid with a molar concentration of 3 moles per liter, adjust the average particle size of the synthesized phosphor to 15 μm, then wash the phosphor repeatedly with distilled water until it is neutral, and then remove the phosphor Put the powder in an alumina container, reduce it at 1400°C for 4 hours, and use hydrogen as the reducing atmosphere to get the desired ph...

Embodiment 2

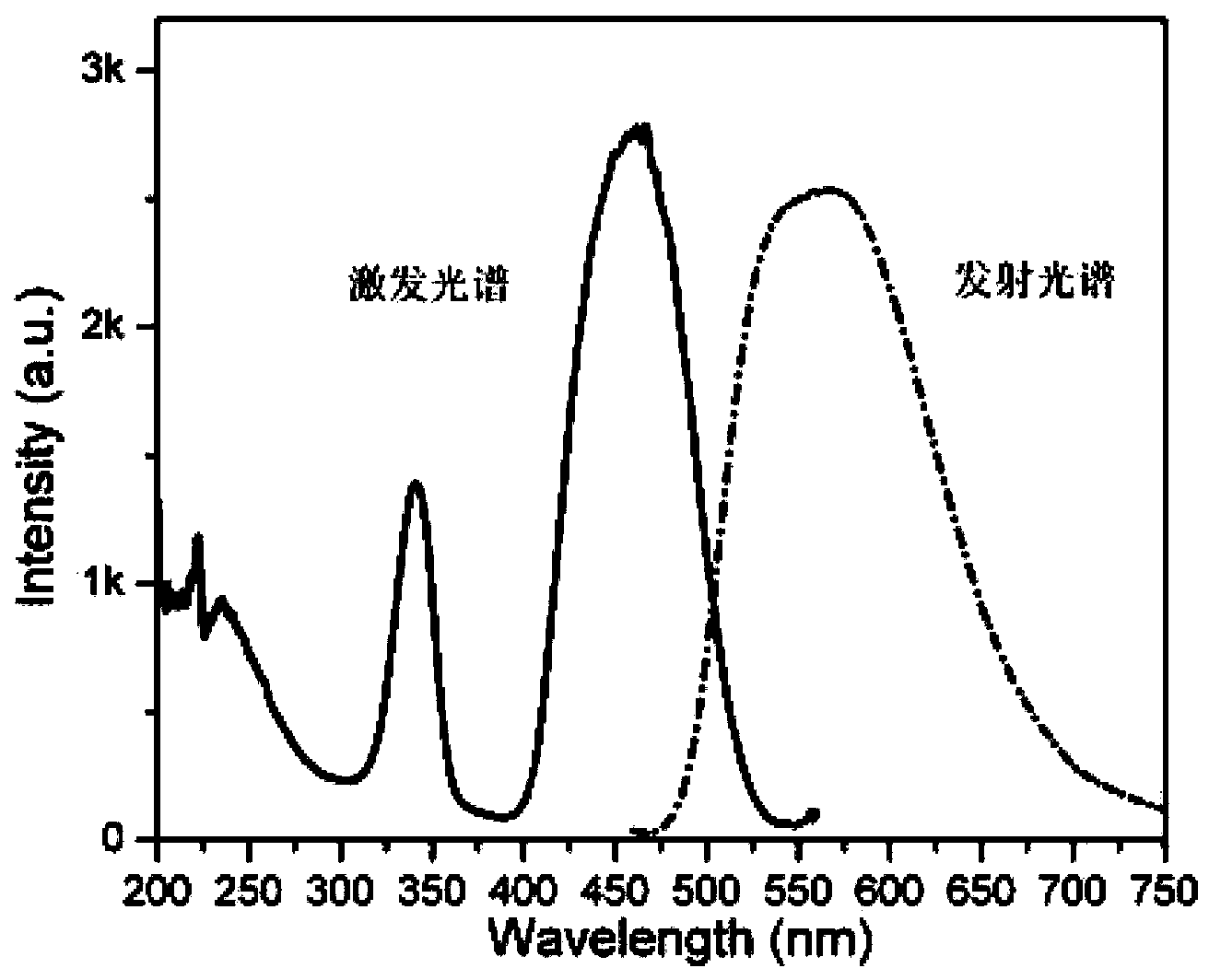

[0050] The chemical formula of embodiment 2 fluorescent powder is Y 2.89 Ce 0.09 Sr 0.02 al 4.98 Si 0.02 o 12

[0051] The raw material is Y 2 o 3 (analytical pure), CeO 2 (analytical pure), SrCO 3(analytical pure), Al 2 o 3 (analytical pure) and SiO 2 (analytical pure). The molar ratio is 1.445:0.09:0.02:2.49:0.02, the raw materials are ground and mixed, placed in a zirconia container, and sintered at a temperature of 1550°C for 4 hours, the sintering atmosphere is a mixture of nitrogen and hydrogen, and the sintered powder Take it out from the container, choose crushing, grading, and treat it with hydrochloric acid with a molar concentration of 3 moles per liter, adjust the average particle size of the synthesized phosphor to 15 μm, then wash the phosphor repeatedly with distilled water until it is neutral, and then remove the phosphor Put the powder in an alumina container, and reduce it at 1350° C. for 4 hours, and the reducing atmosphere is hydrogen, and then...

Embodiment 3

[0052] The chemical formula of embodiment 3 fluorescent powder is Y 2.88 Ce 0.09 Sr 0.03 al 4.97 Si 0.03 o 12

[0053] The raw material is Y 2 o 3 (analytical pure), CeO 2 (analytical pure), SrCO 3 (analytical pure), Al 2 o 3 (analytical pure) and SiO 2 (analytical pure). The molar ratio is 1.44:0.09:0.03:2.485:0.03. Grind and mix the raw materials and place them in an alumina container. Sinter at 1500°C for 4 hours. The sintering atmosphere is a mixture of nitrogen and hydrogen. The sintered powder Take it out from the container, choose crushing, grading, and treat it with hydrochloric acid with a molar concentration of 3 moles per liter, adjust the average particle size of the synthesized phosphor to 15 μm, then wash the phosphor repeatedly with distilled water until it is neutral, and then remove the phosphor Put the powder in an alumina container, reduce it at 1400°C for 4 hours, and use hydrogen as the reducing atmosphere to get the desired phosphor. Ce in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Color temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com