Large-size neodymium iron boron diffusion magnet and preparation method thereof

A NdFeB, large-size technology, applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems of insufficient diffusion power, limited, low percentage of rare earth elements, etc., to shorten the heat treatment time, The effect of flexible process and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

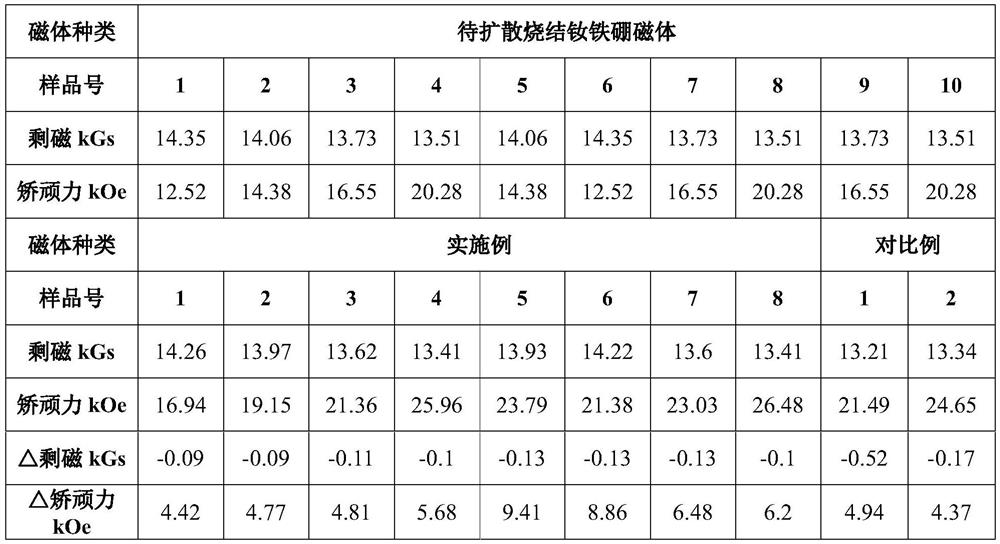

Examples

preparation example Construction

[0033] The first aspect of the present invention provides a method for preparing a large-size NdFeB diffusion magnet, comprising the following steps:

[0034] forming a heavy rare earth metal layer on the surface of the metal foil to obtain a modified metal foil, the metal foil being aluminum foil or copper foil;

[0035] Combine N pieces of NdFeB magnets to be diffused and sintered with N-1 pieces of the modified metal foil to obtain an assembly, wherein, N≥3, and the modified metal foils are respectively arranged on adjacent NdFeB magnets to be diffused and sintered between boron magnets;

[0036] The combination is heat treated to obtain a large-size NdFeB diffusion magnet.

[0037] In the present invention, the modified metal foil is obtained by forming a heavy rare earth metal layer on the surface of the metal foil, and then the modified metal foil is directly attached to the NdFeB magnet to be diffused and sintered, thereby eliminating the need for coating and coating o...

Embodiment 1

[0050] Get Modified Aluminum Foil

[0051] A modified aluminum foil 1 was obtained by depositing a 3 μm dysprosium metal layer on both surfaces of an aluminum foil with a thickness of 1 μm by thermal evaporation deposition technology.

[0052] get combination

[0053] Pr the performance as N52 6 Nd 24 Fe 69 B The sintered NdFeB magnet is processed into a magnet to be diffused with a minimum size direction of 4mm (denoted as a magnet to be diffused 1), and the direction of the minimum size is parallel to the direction of easy magnetization; insert 3 pieces of modified aluminum foil 1 between the 4 pieces of magnets to be diffused , to obtain assembly 1, wherein the thickness of the first piece and the fourth piece of magnet is 2mm.

[0054] heat treatment

[0055] After heat treatment of assembly 1 at 850°C for 30 hours, the diffusion magnet was subjected to secondary heat treatment at 500°C for 5 hours to obtain a large-sized NdFeB diffusion magnet with a diffusion d...

Embodiment 2

[0057] Get Modified Aluminum Foil

[0058] With embodiment 1.

[0059] get combination

[0060] Pr with performance as 50M 6 Nd 23.5 Dy 0.8 Fe 68.7 B The sintered NdFeB magnet is processed into a magnet to be diffused with a minimum size direction of 3 mm (denoted as a magnet to be diffused 2), and the minimum size direction is perpendicular to the direction of easy magnetization; 4 pieces of modified aluminum foil 1 are inserted between 5 pieces of magnets to be diffused , Obtain assembly 2, wherein the thickness of the first piece and the fifth piece of magnet is 1.5mm.

[0061] heat treatment

[0062] After heat treatment of assembly 2 at 875°C for 10 hours, the diffusion magnet was subjected to secondary heat treatment at 520°C for 5 hours to obtain a large-sized NdFeB diffusion magnet with a diffusion direction size of 12mm, which was designated as sample 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com