Oil fume suction control method of intelligent breathing range hood and range hood

A control method and a technology for a range hood, which are applied in the fields of removing oil fume, heating method, and household heating, etc., can solve the problems such as the amount of oil fume cannot be accurately reflected, the amount of oil fume generated is small, and the detection method is defective, so as to achieve reliable performance, Reduced impact, low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

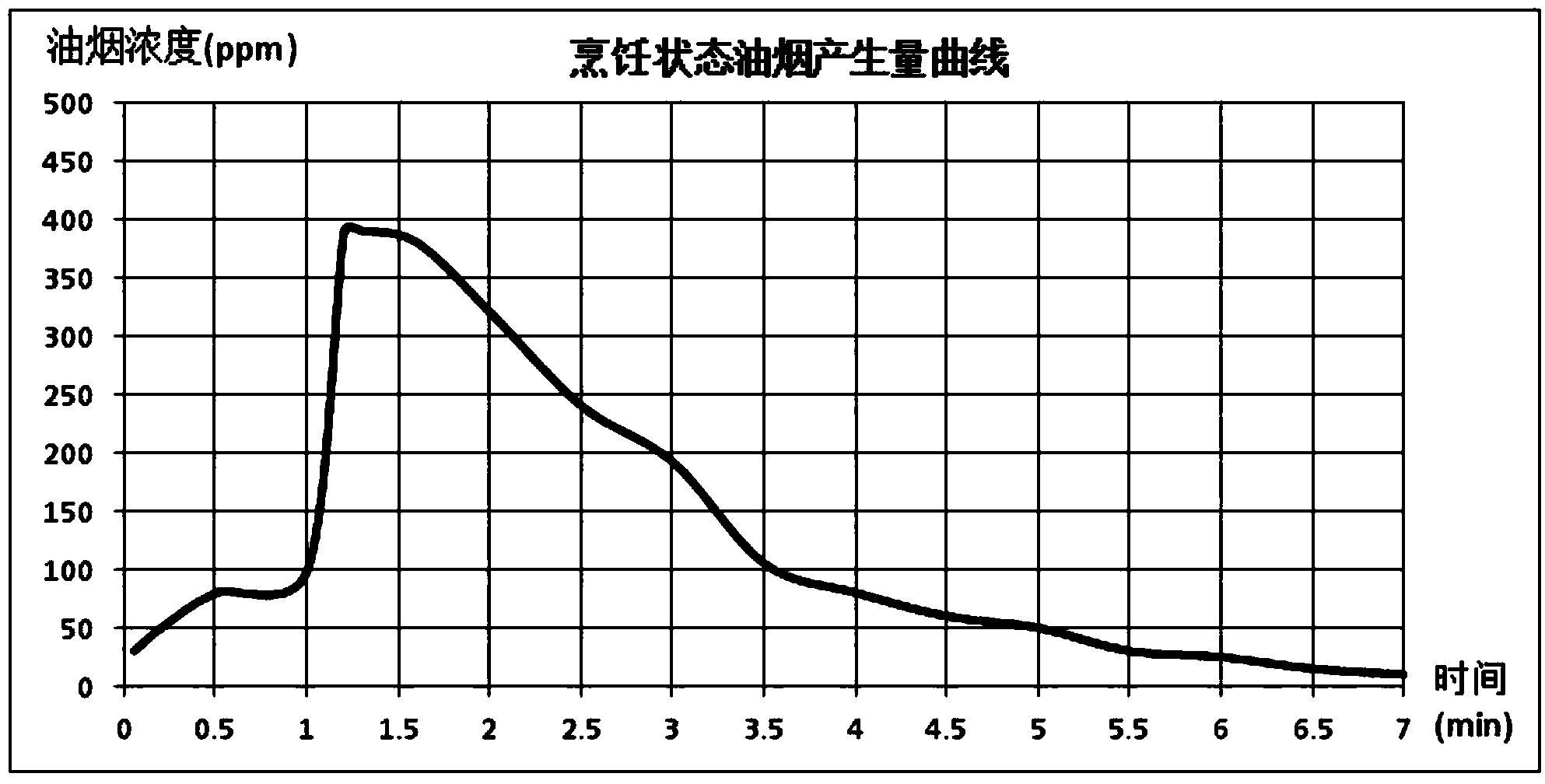

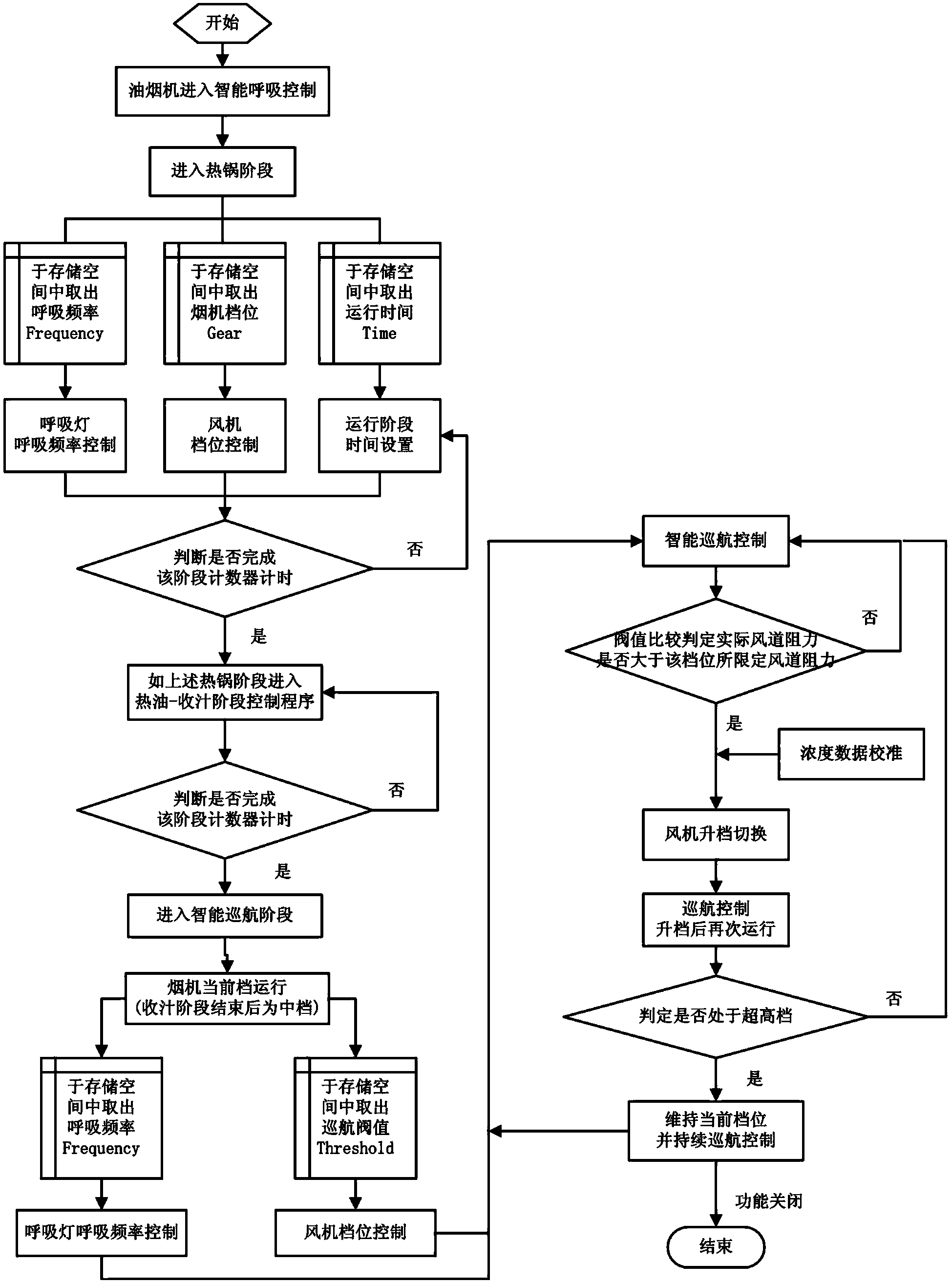

[0020] The present invention is a control method based on the study of the curve of the amount of oil fume produced under the state of food cooking. The generation of oil fume is related to temperature. Taking soybean oil as an example, the smoke point is 234°C. The actual oil fume is caused by local heating. It will deviate from the theoretical value. According to the Fourier heat conduction law, the heat absorbed by an object per unit time is proportional to the temperature difference, so when the temperature is T, the heat absorbed per unit time is Q=K(a-T), and the unit The increase in temperature within the time is dT / dt=Q / (mc)=K(a-T) / (mc), when the initial value t=0, T=b, the function of temperature change with time is: T=a- (a+b)e^(-kt / mc), where m: the mass of the heated object, c: the specific heat capacity (c water = 4.2×103J / (kg / ℃)), a: the temperature rise value, K is the cooking oil Temperature Coefficient. In the preheating and flaming part, the amount of soot g...

Embodiment 2

[0036] The difference between this embodiment and the range hood of Embodiment 1 is that the main controller of the range hood is provided with a signal receiving unit linked with the cooker, and the cooker is provided with an ignition signal transmitting unit. The signal transmitting unit transmits a trigger signal to the signal receiving unit of the range hood, the main controller triggers and starts the intelligent breathing program through the received trigger signal, and the range hood starts to execute the smoking control method.

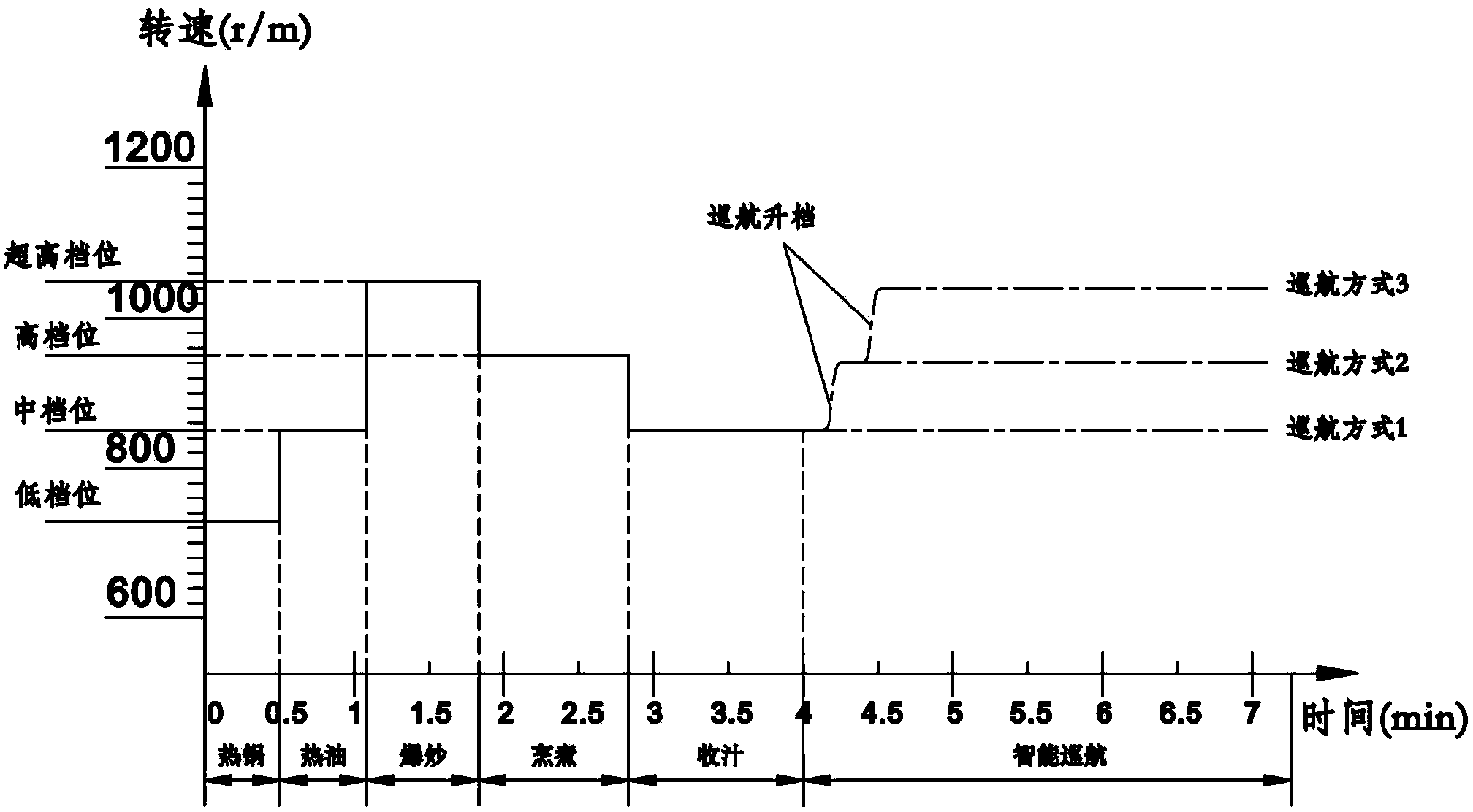

[0037] The difference between the smoking control method in this embodiment and Embodiment 1 is that, as Figure 4 , Figure 5 , including the following stages:

[0038] Pre-processing stage: the main controller controls the operation of the middle gear of the fan. The speed of the fan is 800≤V<900rpm. The running time of the phase ends at 60-80s after the start of the smoking control method, and preferably ends after 60s after the start;

...

Embodiment 3

[0045] The difference between this embodiment and Embodiment 1 is that in this embodiment, the motor adopts a DC motor, and under the super high gear, there are multi-level gears for smooth speed regulation, such as Image 6 , the smoking control methods include:

[0046] Stir-fry stage: the stir-fry stage is executed synchronously when the smoking control method is started. The main controller controls the super-high-end operation of the fan. Adopt deep breathing and smoking method, continue to run for 180s in the frying stage, and then downshift to enter the next stage;

[0047] Post-processing stage: the main controller controls the fan to run at a speed of 850 rpm, and the post-processing stage lasts for 240s;

[0048] Intelligent cruising stage: It starts synchronously when the post-processing stage is started. The air duct resistance detection device detects the air duct resistance of the range hood in real time, and compares it with the threshold set for the correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com