Middle-low-temperature flue gas desulfurization, dedusting and denitration and denitration catalyst thermal-desorption integrated device

A denitrification catalyst, desulfurization and dust removal technology, applied in the direction of catalyst regeneration/reactivation, physical/chemical process catalyst, combined device, etc., can solve the problems that it is impossible to install bag filter and denitration reactor at the same time, affecting the efficiency of medium and low temperature denitrification, etc. Achieve the effects of improving catalytic efficiency and service life, reducing operating costs, and improving denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

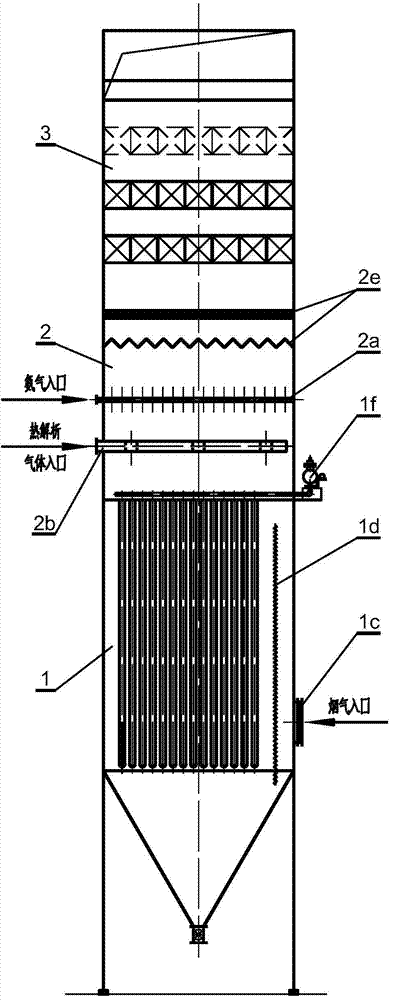

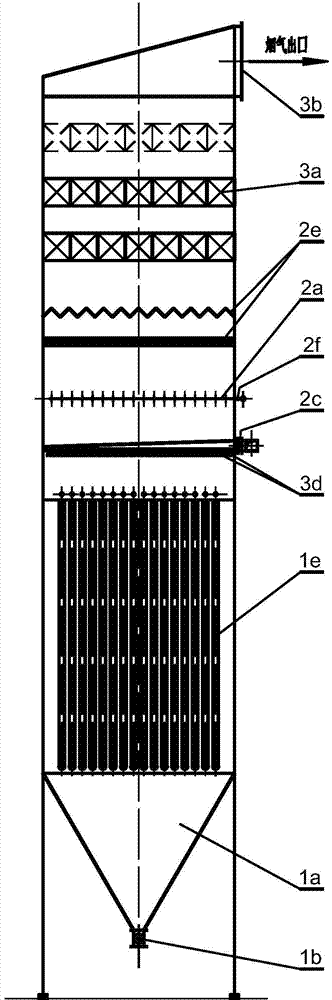

[0024] See Figure 1-Figure 2 , is a structural schematic diagram of the present invention, the medium and low temperature flue gas desulfurization, dust removal, denitrification and denitrification catalyst thermal analysis integrated device of the present invention, including a desulfurization, dust collection and purification section 1, an analysis and ammonia injection mixing section 2 and a bottom-up integrated in a tower body The denitrification reaction section 3, the desulfurization dust collection and purification section 1 is composed of an ash bin 1a, an airtight ash discharge valve 1b, a flue gas inlet 1c, a uniform air flow deflector 1d, a filter bag 1e and a pulse injection device 1f; The ammonia mixing section 2 is composed of an ammonia injection structure 2a, a thermal analysis gas delivery injection structure 2b, and a mixing and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com