A kind of pig blood protein powder separation device

The technology of a separation device and a cyclone separation device, which is applied in the field of pig blood reuse processing devices, can solve the problems of undisclosed preparation devices, the production performance needs to be improved, the production process is not environmentally friendly enough, etc., and achieves good recovery performance, sufficient recovery, and sufficient The effect of residual heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

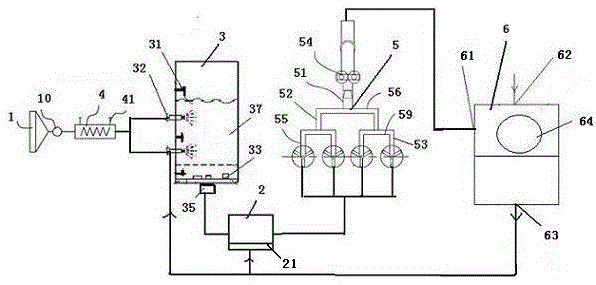

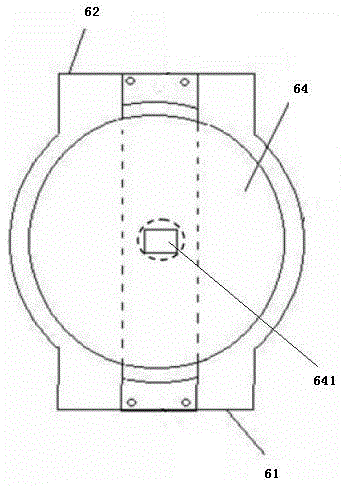

[0032] Such as figure 1 , figure 2 As shown, the air filter 1 is connected with the first inlet of the drying device 2 for drying the porcine blood protein powder; the second inlet of the drying device 2 is connected with the spray device 3 for granulating the porcine hemoglobin solution into the porcine blood protein powder;

[0033] Between the air filter 1 and the drying device 2 is connected an air heater 4 for heating the air thereby providing hot air; the air filter 1 communicates with the air inlet of the two-fluid atomizing spray gun 31; A blower or an air pump 10 is connected between the spraying devices 3 .

[0034] The spray device 3 comprises a granulation fluidized bed 37, a knife 32 arranged on the side wall of the granulation fluidized bed 37, two sides of the knife 32 are symmetrically provided with a two-fluid atomization spray gun 31, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com