Preparing method of amino-functionalized mesoporous cerium oxide

An amino function, cerium oxide technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., to achieve the effects of good repeatability, large adsorption capacity, and simple synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

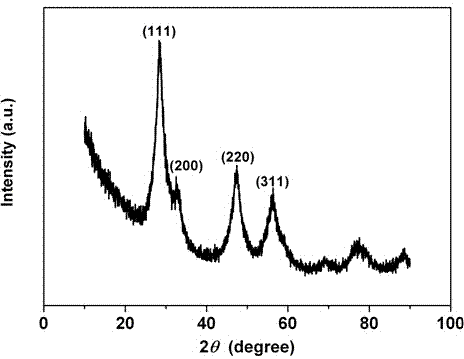

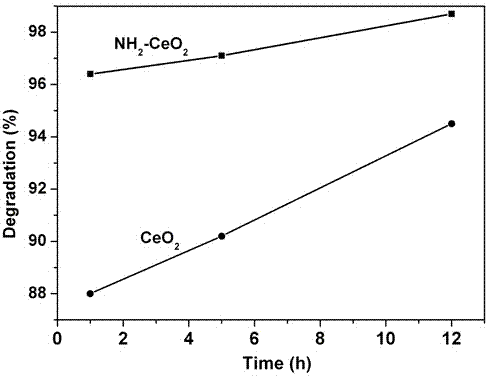

Image

Examples

Embodiment 1

[0033] Add 1.74 g P in 15 ml ethanol and 7.5 ml deionized water 123 , stirred in a water bath at 40 ℃ for 40 min to fully dissolve; 1.20 g Ce(NO 3 ) 3 ·6H 2 O was dissolved in 7.5 ml of deionized water, and this solution was added dropwise to P 123 In the solution, after magnetic stirring for 60 min, 28% concentrated ammonia water was added dropwise until the pH value of the solution was 9; after the above alkaline solution was cooled to room temperature, 30% H 2 o 2 7.5 ml to make the solution turn reddish-brown, continue to stir until the reddish-brown precipitate is evenly suspended in the solution, then transfer the mixed solution to a polytetrafluoroethylene-lined autoclave, and conduct a hydrothermal reaction at 90 °C for 20 h. After filtering, washing with water, washing with ethanol, and drying at 40 °C, the pre-product was obtained; the pre-product was extracted with absolute ethanol, filtered, washed with ethanol, and dried at 40 °C to obtain a mesoporous cerium...

Embodiment 2

[0035] Add 5.12 g P in 20 ml ethanol and 12.5 ml deionized water 123 , stirred in a water bath at 60 ℃ for 40 min to fully dissolve; 4.80 g Ce(NO 3 ) 3 ·6H 2 O was dissolved in 12.5 ml of deionized water, and this solution was added dropwise to P 123 In the solution, after magnetic stirring for 60 min, 28% concentrated ammonia water was added dropwise until the pH value of the solution was 10; after the above alkaline solution was cooled to room temperature, 30% H 2 o 2 12.5 ml to make the solution turn reddish-brown, continue to stir until the reddish-brown precipitate is evenly suspended in the solution, then transfer the mixed solution to a high-pressure reactor with a polytetrafluoroethylene liner, and conduct a hydrothermal reaction at 120 °C for 30 h. After filtering, washing with water, washing with ethanol, and drying at 70 °C, the pre-product was obtained; the pre-product was extracted with absolute ethanol, filtered, washed with ethanol, and dried at 70 °C to ob...

Embodiment 3

[0037] Add 1.74 g P in 15 ml ethanol and 7.5 ml deionized water 123 , stirred in a water bath at 40 ℃ for 40 min to fully dissolve; 1.20 g Ce(NO 3 ) 3 ·6H 2 O was dissolved in 7.5 ml of deionized water, and this solution was added dropwise to P 123 In the solution, after magnetic stirring for 60 min, 28% concentrated ammonia water was added dropwise until the pH value of the solution was 9; after the above alkaline solution was cooled to room temperature, 30% H 2 o 2 7.5 ml to make the solution turn reddish-brown, continue to stir until the reddish-brown precipitate is evenly suspended in the solution, then transfer the mixed solution to a polytetrafluoroethylene-lined autoclave, and conduct a hydrothermal reaction at 90 °C for 20 h. After filtering, washing with water, washing with ethanol, and drying at 40 °C, the pre-product was obtained; the pre-product was extracted with absolute ethanol, filtered, washed with ethanol, and dried at 40 °C to obtain a mesoporous cerium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com