Device and method for automatic hole making of stretched skin parts

An automatic manufacturing and parts technology, which is applied to positioning devices, feeding devices, aircraft parts, etc., can solve the problems of easy damage to hoisting, insufficient hole-making accuracy, and difficult to achieve, and achieves controllable process parameters, high hole-making accuracy, and high precision. Indestructible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1 A kind of skin stretching part mold

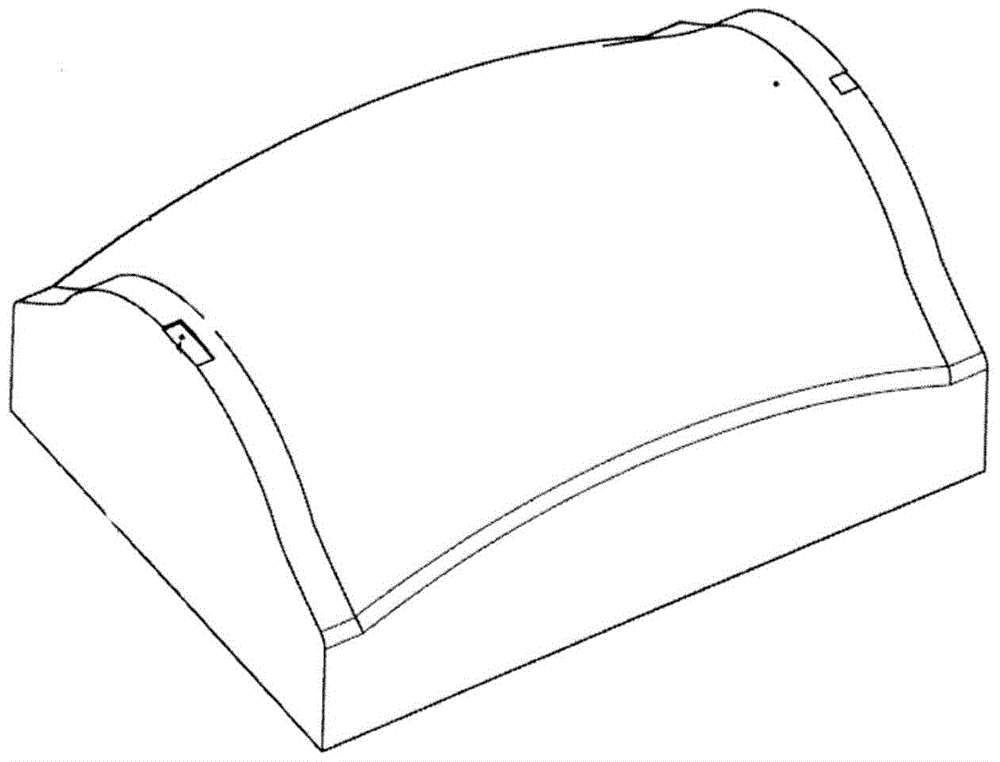

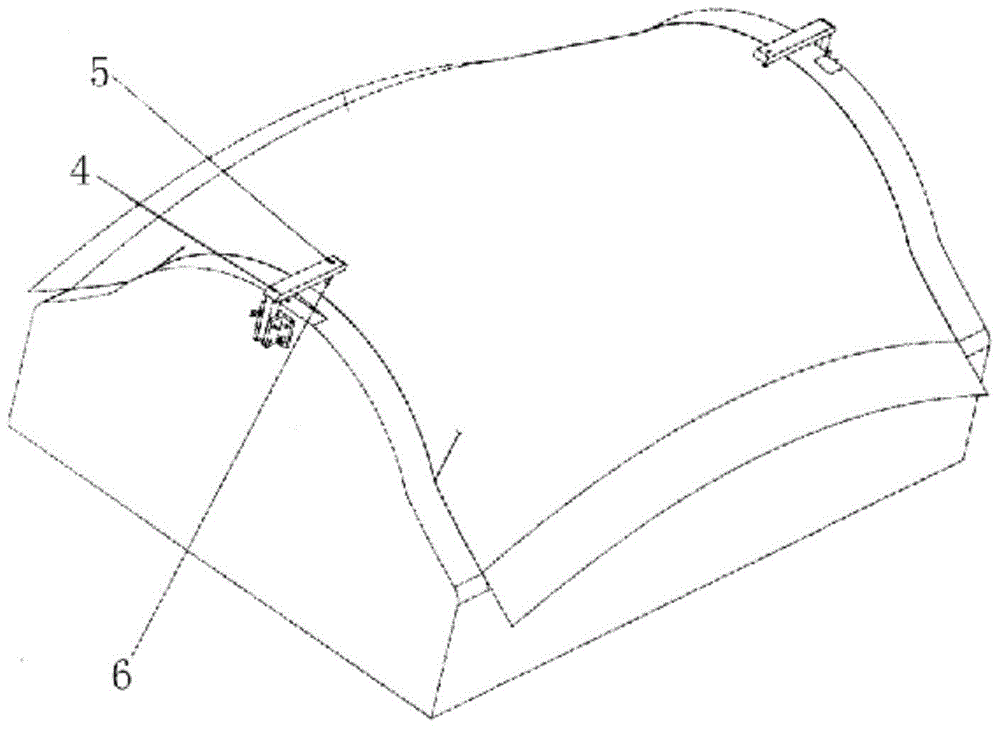

[0022] Such as Figure 4 As shown, the mold for the stretched skin part is composed of an automatic hole-making device (100) for the stretched skin part and a mold main body (200).

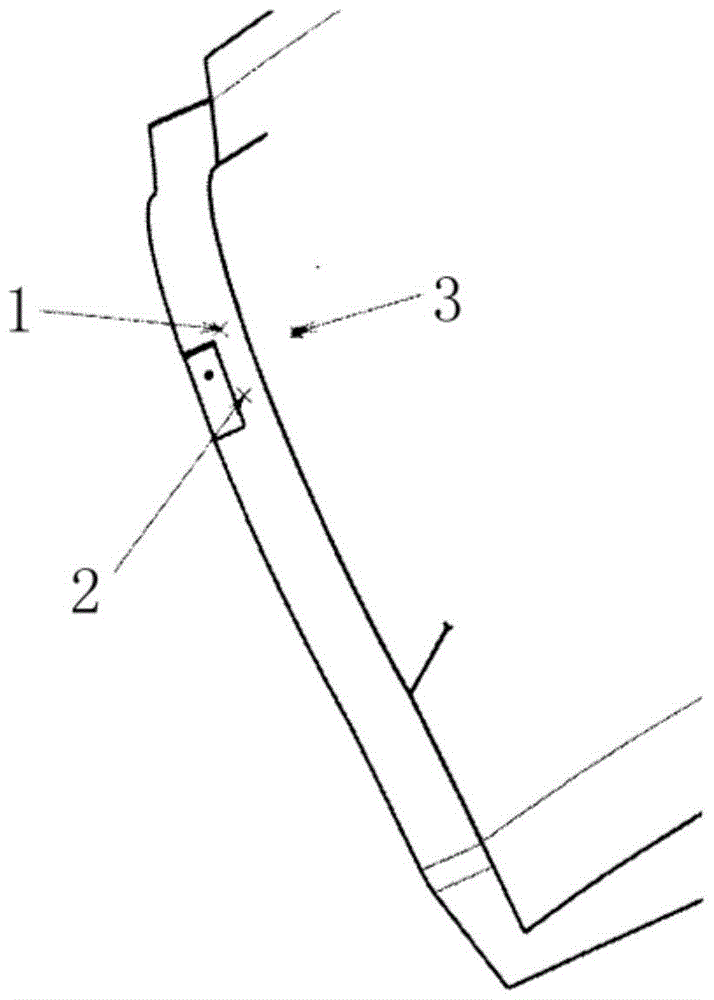

[0023] Automatic hole-making devices (100) are installed at both ends of the mold main body (200). The upper end of the shell (2) of the automatic hole-making device (100) and the profiling plate (16) are fastened together with the mold main body (200) by reaming hole screws (15).

[0024] Such as Figure 5 As shown, the structure of the automatic hole-making device (100) for skin stretching parts is: the screw nut (4) matched with the lead screw (3) is fastened to the lower end of the shell (2) through the screw thread of its outer diameter, and Set screws limit the position; the lower end cover (1) is fastened to the lower end of the shell (2) through threads, and is limited by the set screw; the lower end cover (1), the shell (2), the...

Embodiment 2

[0026] Embodiment 2 A kind of automatic hole-making method of skin stretching parts

[0027] Using the mold of Example 1, the processing of the process hole (300) is automatically completed by the automatic hole-making device installed on the mold. Put the skin on the mold, start the switch of the automatic hole making device, and complete the corresponding process hole processing.

[0028] The method is as follows: place the skin stretching part on the mold main body (200), start the motor, the motor rotates, and the output shaft at the lower end drives the double-stage planetary reducer to rotate, and the lead screw and the output shaft of the reducer are formed into an integrated structure; Through the cooperation between the output shaft of the double-stage planetary reducer and the screw nut, as well as the lead screw and the screw nut, the drill bit is pushed upward to realize automatic feeding, and the drill bit is driven to rotate to realize automatic hole making.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com