Method and system for treating crude trichlorosilane

A technology for crude trichlorosilane and trichlorosilane, which is applied to halosilanes, halogenated silicon compounds, etc., can solve the problems that affect the normal operation of the reduction furnace, increase the production and operation cost, and the reduction furnace is prone to atomization. The effect of improving the utilization rate of raw materials, reducing the processing cost, and being easy to separate from the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

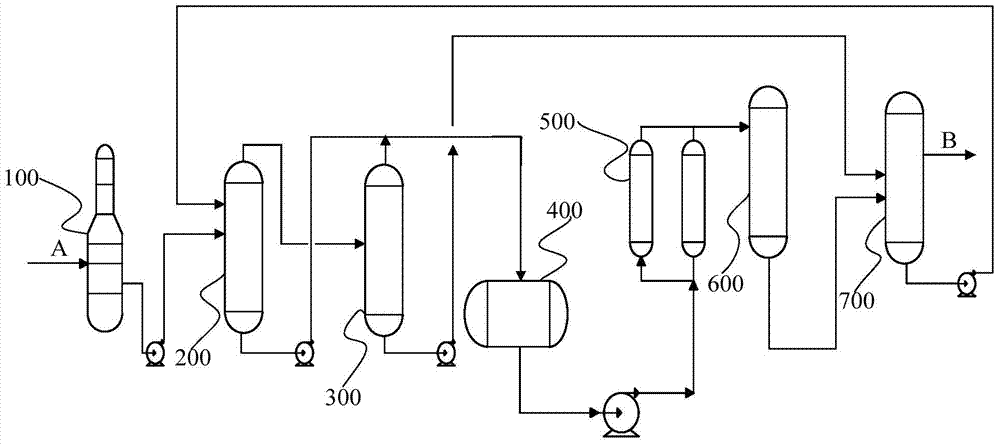

[0117] Composition of crude trichlorosilane: 36.69wt% of dichlorodihydrosilane, 1.01wt% of trichlorosilane, 62.3wt% of silicon tetrachloride and trace impurities containing boron and phosphorus elements;

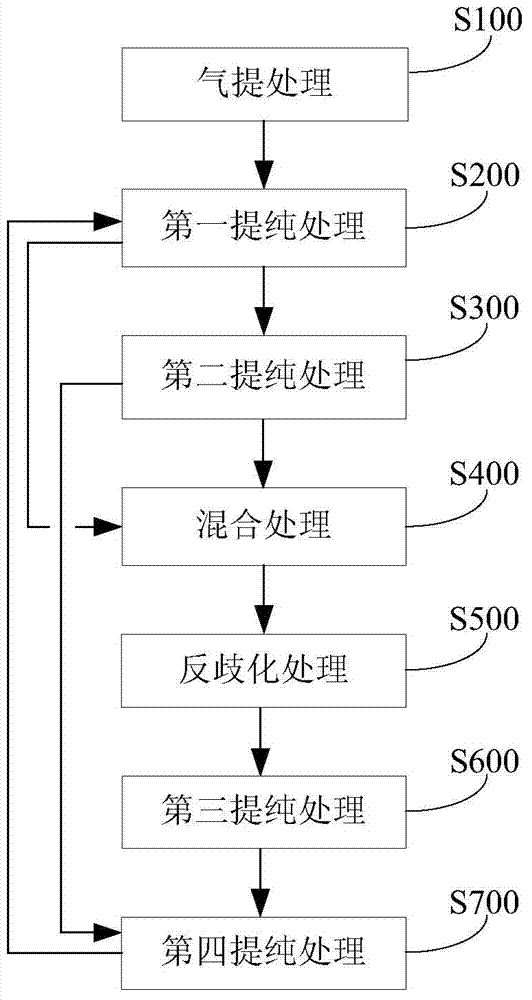

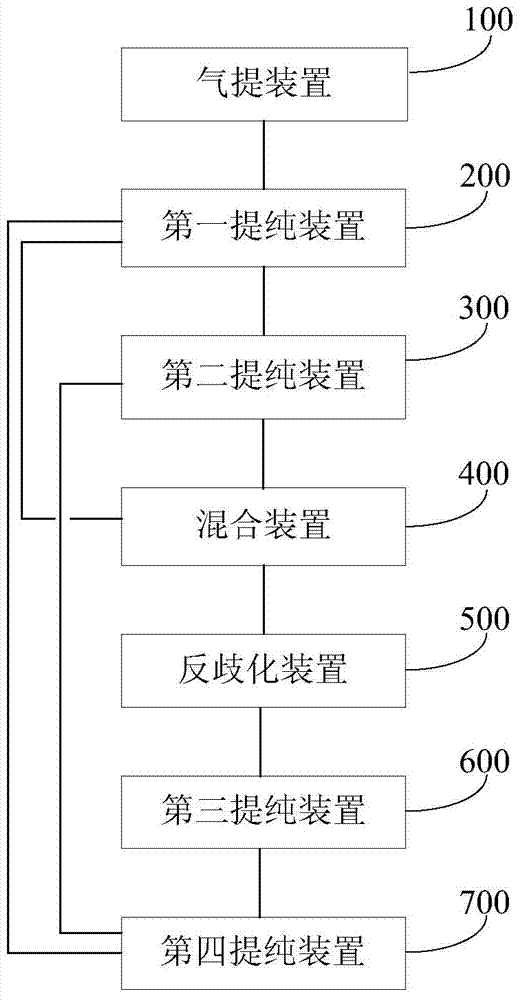

[0118] Processing method: reference image 3 , the crude trichlorosilane A obtained by the cold hydrogenation treatment unit is passed into the gas stripping device 100 at a pressure of 0.6 MPa, a temperature of the tower bottom of 137 degrees Celsius, and a temperature of 38.5 degrees Celsius at the top of the tower to carry out gas stripping treatment to obtain The mixture of dihydrosilane, trichlorosilane and silicon tetrachloride, then the mixture containing dichlorodihydrosilane, trichlorosilane and silicon tetrachloride is passed into the first purification device 200 at a pressure of 0.48MPa, The first purification treatment is carried out at a tower top temperature of 89 degrees Celsius and a tower bottom temperature of 129 degrees Celsius to obtain a first tower ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com