Integrated device for preprocessing of printing ink wastewater and technological process of integrated device

A technology of ink waste water and integrated device, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. major problems, to achieve the effect of reducing the investment in supporting civil works, reducing the input cost, and reducing the investment in civil works

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

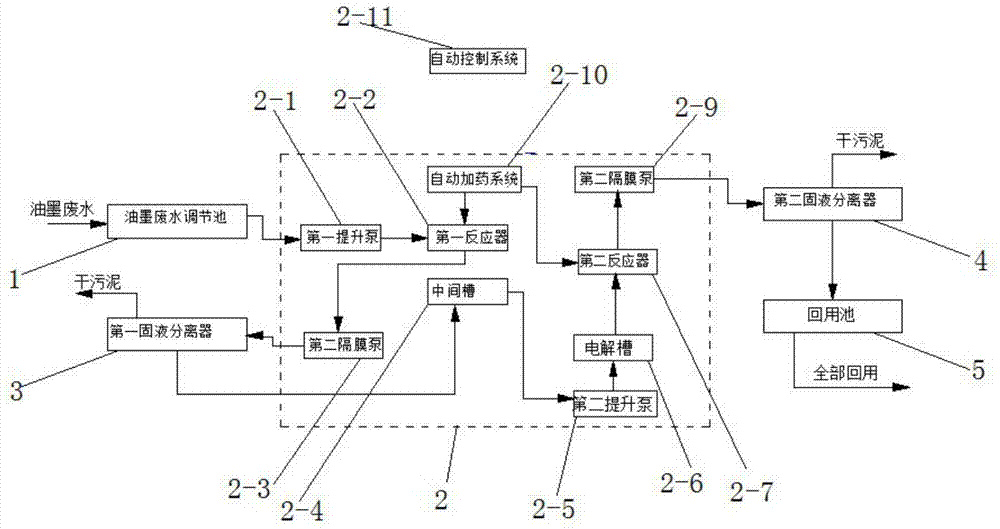

[0026] As shown in the figure, the ink wastewater pretreatment integrated device 2 includes a first lift pump 2-1, a first reactor 2-2, a first diaphragm pump 2-3, an intermediate tank 2-4, and a second lift pump 2-5 , electrolyzer 2-6, second reactor 2-7, second diaphragm pump 2-9, automatic dosing system 2-10, automatic control system 2-11. The automatic dosing system 2-10 adds medicine to the first reactor 2-2 and the second reactor 2-7 respectively.

[0027] The automatic control system 2-11 includes a touch screen, PLC control program, the PLC control program controls the dosing time and dosage of the automatic dosing system 2-10, the working time of the first lifting pump 2-1, and the working time of the first reactor 2-2 Time, the working time of the first solid-liquid separator 3, the working time of the first diaphragm pump 2-3, the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com