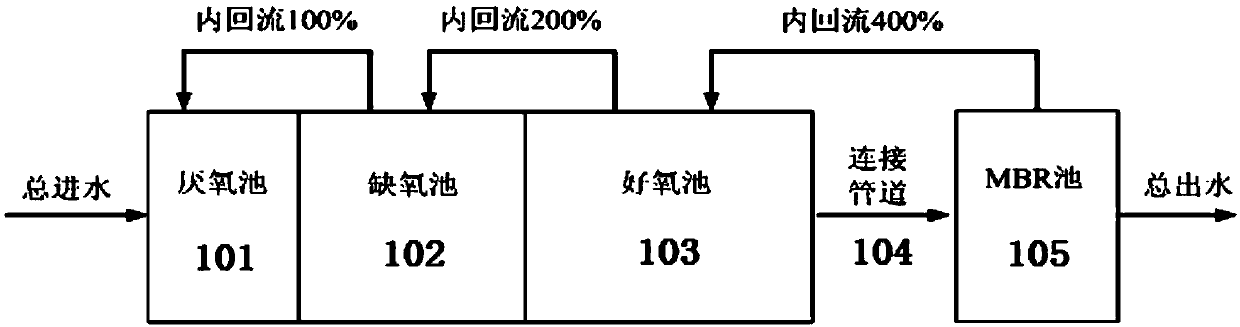

Step-feed multi-stage AO+MBR (Anoxic/Oxic+Membrane Biological Reactor) nitrogen and phosphorus removal system

A technology for water inflow, nitrogen and phosphorus removal in stages, applied in the field of nitrogen and phosphorus removal systems, can solve problems such as increased energy consumption, and achieve the effects of reducing workload, stable effect and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

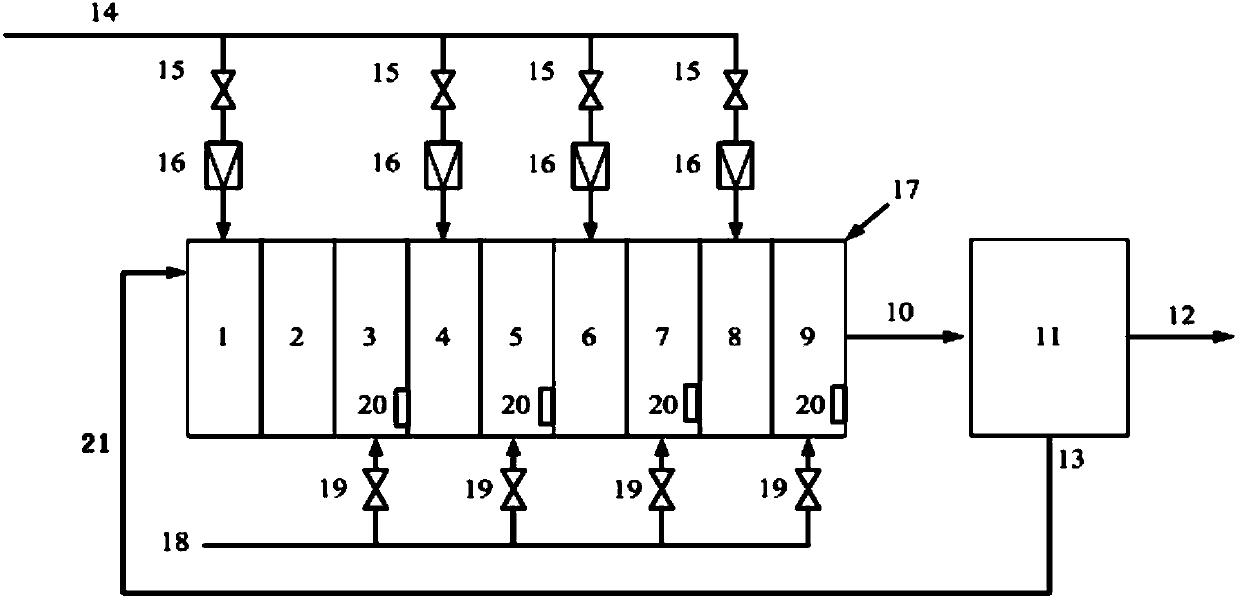

[0028] A multi-stage AO+MBR denitrification and phosphorus removal system of the present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings.

[0029] like figure 2 As shown, the influent multistage AO+MBR denitrification and phosphorus removal system of the present invention includes a multistage AO biological reaction tank 17 and an MBR connected to the sewage outflow end of the multistage AO biological reaction tank 17 through a connecting pipe 10 pool 11, the multi-stage AO biological reaction pool 17 includes an anaerobic pool 1, a primary anoxic zone 2, a primary aerobic zone 3, a secondary anoxic zone 4, and a secondary aerobic zone 5 connected in sequence , third-level anoxic zone 6, third-level aerobic zone 7, fourth-level anoxic zone 8, and fourth-level aerobic zone 9, among which, the fourth-level water intake point adopts different flow distribution strategies according to different treatment requirements, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com