Fiberglass-reinforced plastic septic tank cylinder/bracing ring integrated winding technique

A glass tempering and winding forming technology, which is applied in glass production, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of unstable product quality, large waste of raw materials, and large solid waste, so as to facilitate quality control, waste reduction, solid waste, etc. Effect of Waste Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

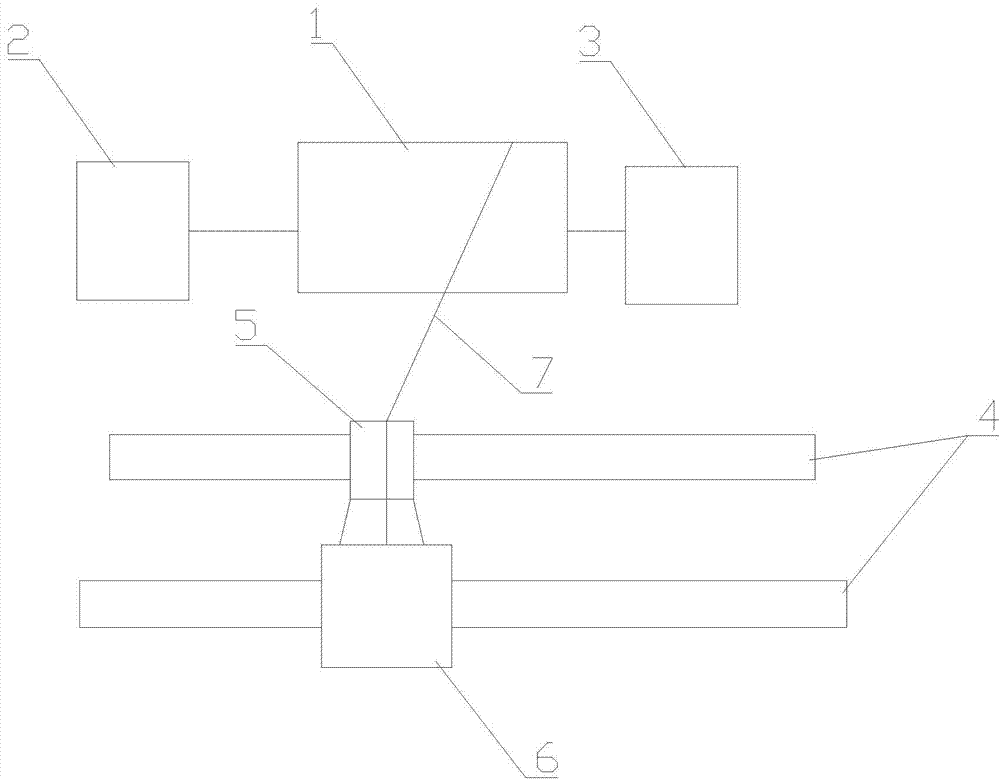

[0034] Such as figure 1 As shown, a fiberglass septic tank body and support ring integrated winding molding process, including the following steps:

[0035] a, the mold 1 used for winding the fiberglass fiber bundle 7 is fixed on the ground through the head rotation drive device 2 and the fixed support seat 3 of the machine position, and the slide rail 4 is arranged side by side with the mold 1, and the dipping car 5 is arranged on the slide rail 4, The other side of the dipping dolly 5 is provided with a creel 6 for placing the fiberglass bundle 7;

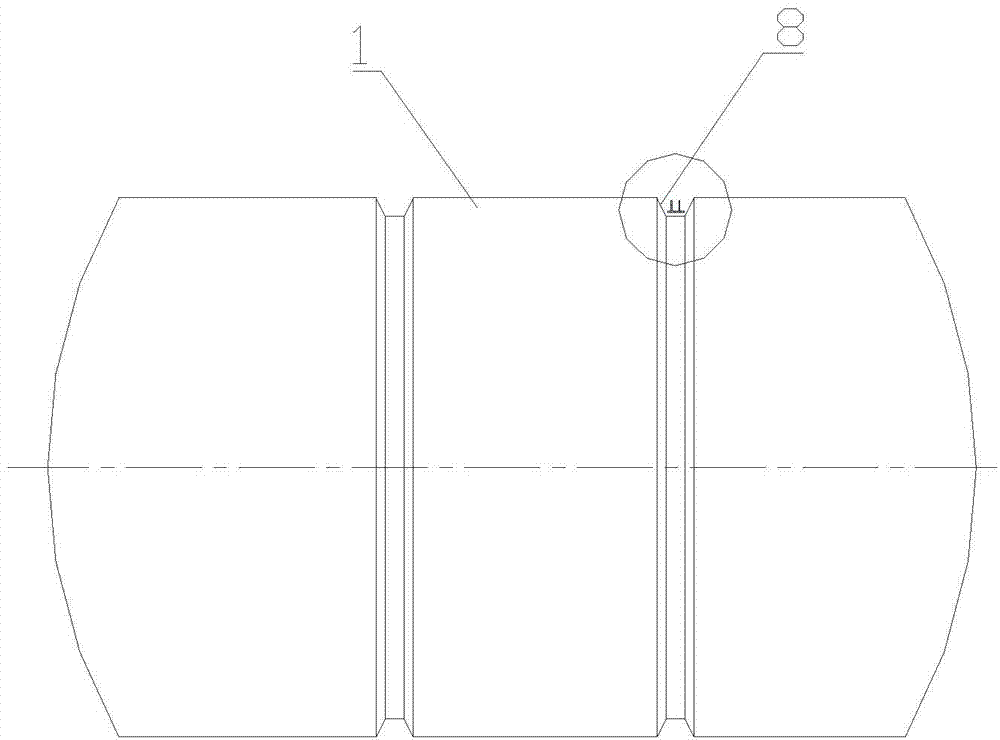

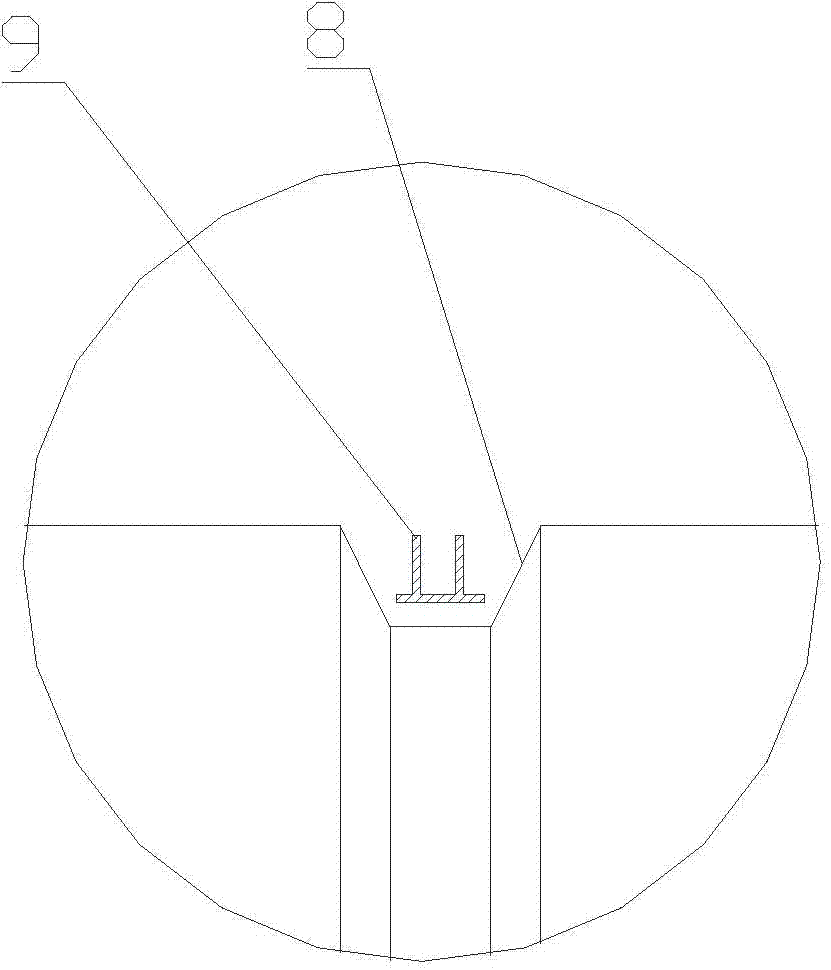

[0036] b. The outer wall of the mold 1 is provided with a circle of grooves 8 at intervals of 1 to 1.5 meters along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com