Ardealite-based cement retarder and preparation method thereof

A coagulant and phosphogypsum technology, which is applied in the field of building material production, can solve the problems of phosphogypsum environmental pollution, etc., achieve significant economic and social benefits, reduce processing pressure, and stabilize performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

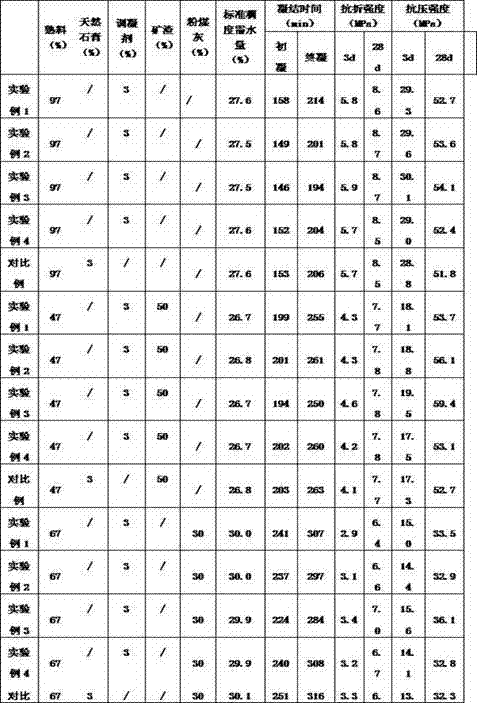

Image

Examples

Embodiment 1

[0025] Mix 92kg of phosphogypsum with 2.6kg of quicklime, 1.3kg of calcined alunite, and 3.1kg of sodium metasilicate to obtain material 1; add 44g of ethylene glycol, 22g of calcium lignosulfonate, and 34g of tetramethylammonium iodide to 8kg Stir evenly in water to obtain material 2; spray material 2 evenly on material 1, age for 48 hours, and dry at 30°C to obtain a phosphogypsum-based cement coagulant.

Embodiment 2

[0027] Mix 94.5kg of phosphogypsum with 1.6kg of quicklime, 1.7kg of calcined alunite, and 1.7kg of sodium metasilicate to obtain material 1; add 200g of ethylene glycol, 200g of calcium lignosulfonate, and 100g of tetramethylammonium iodide Stir evenly in 30kg of water to obtain material 2; spray material 2 evenly on material 1, age for 36 hours, and dry at 50°C to obtain a phosphogypsum-based cement coagulant.

Embodiment 3

[0029] Mix 97kg of phosphogypsum with 1kg of quicklime, 1.4kg of calcined alunite, and 0.5kg of sodium metasilicate to obtain material 1; add 310g of ethylene glycol, 630g of calcium lignosulfonate, and 60g of tetramethylammonium iodide into 40kg of water Stir evenly to obtain material 2; spray material 2 evenly on material 1, age for 24 hours, and dry at 80°C to obtain a phosphogypsum-based cement coagulant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com