Method for extracting and separating L-tryptophan from nitraria tangutorum bobr seeds

A technology of Nitraria japonica seeds and tryptophan, which is applied in the field of separation and extraction of L-tryptophan, and achieves the effects of simple operation, high safety, and environmentally friendly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

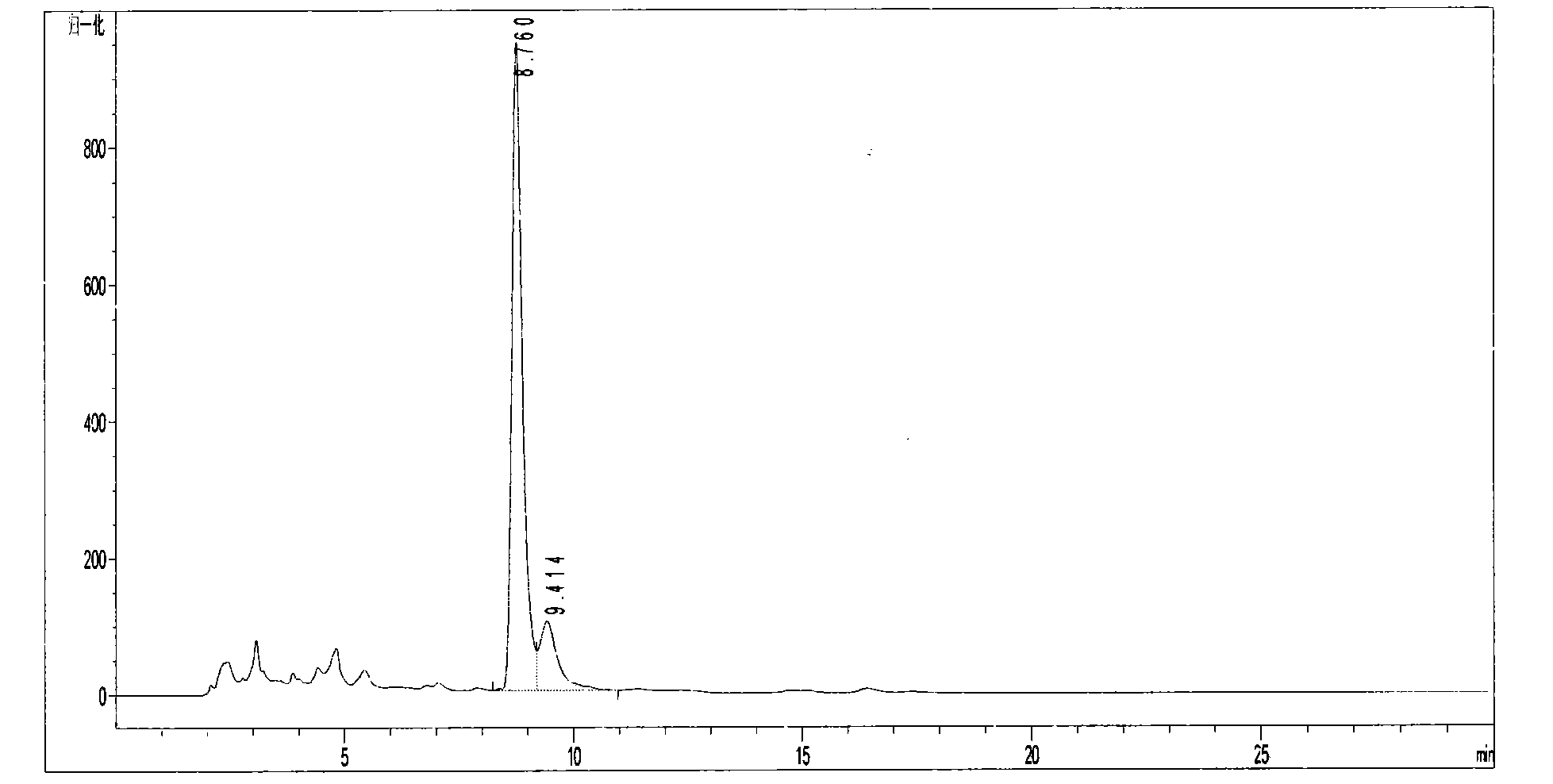

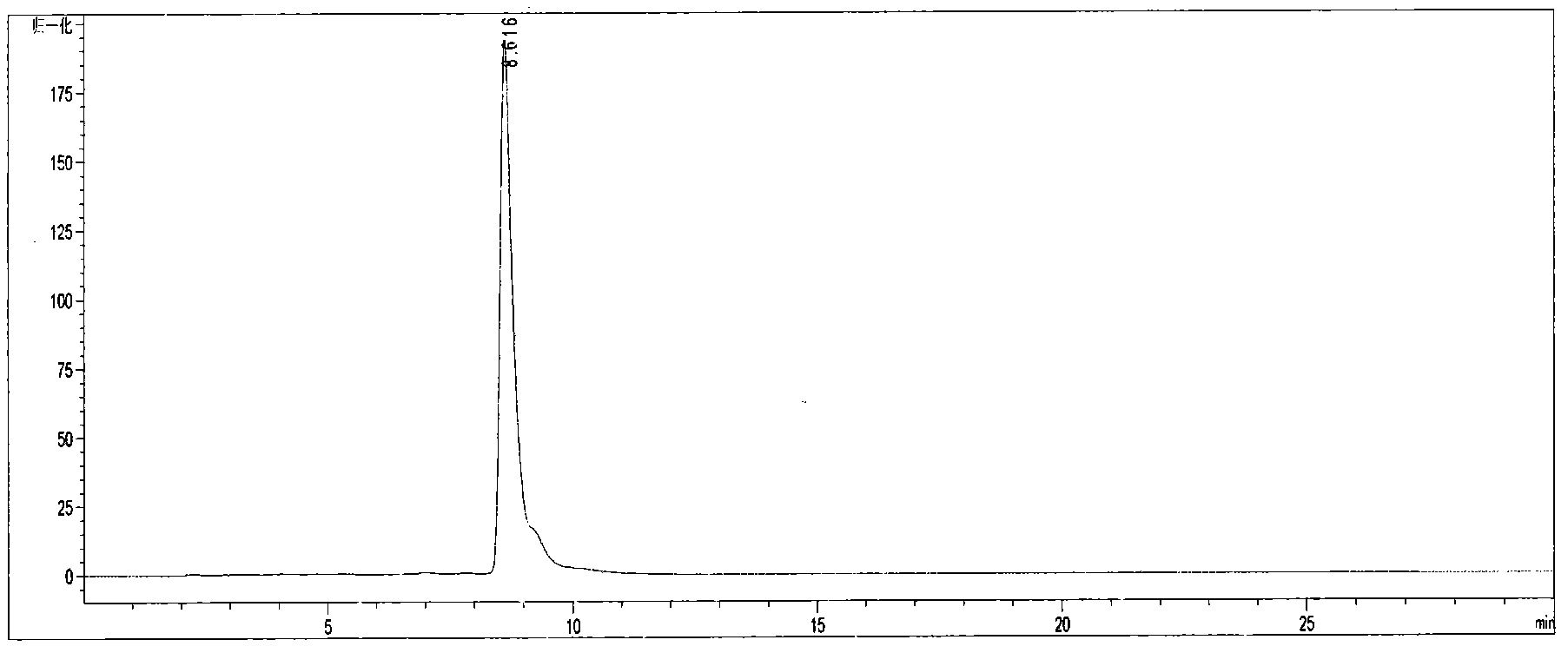

Embodiment 1

[0025] Embodiment 1: L-tryptophan separation and extraction method

[0026] (1) After taking 5 kg of Nitraria seeds and pulverizing them, add 75% ethanol and carry out thermal extraction in a decoction machine at an extraction temperature of 60° C. and an extraction time of 2 hours, and extract three times altogether. The first feed-to-liquid ratio is 1:15, the second feed-to-liquid ratio is 1:12, and the third feed-to-liquid ratio is 1:10. The extracts were combined and concentrated under reduced pressure to 250 mL, then extracted 5 times with petroleum ether, and the extraction ratio of petroleum ether was 250 mL of crude extract and 750 mL of petroleum ether.

[0027] (2) Specifications of macroporous resin column: diameter 5 cm, column height 1.2 m

[0028] Column loading: Take 1.5kg D101 macroporous adsorption resin, put it into the chromatographic column, perform desorption treatment after three days of adsorption, flush the column with water and collect samples for eac...

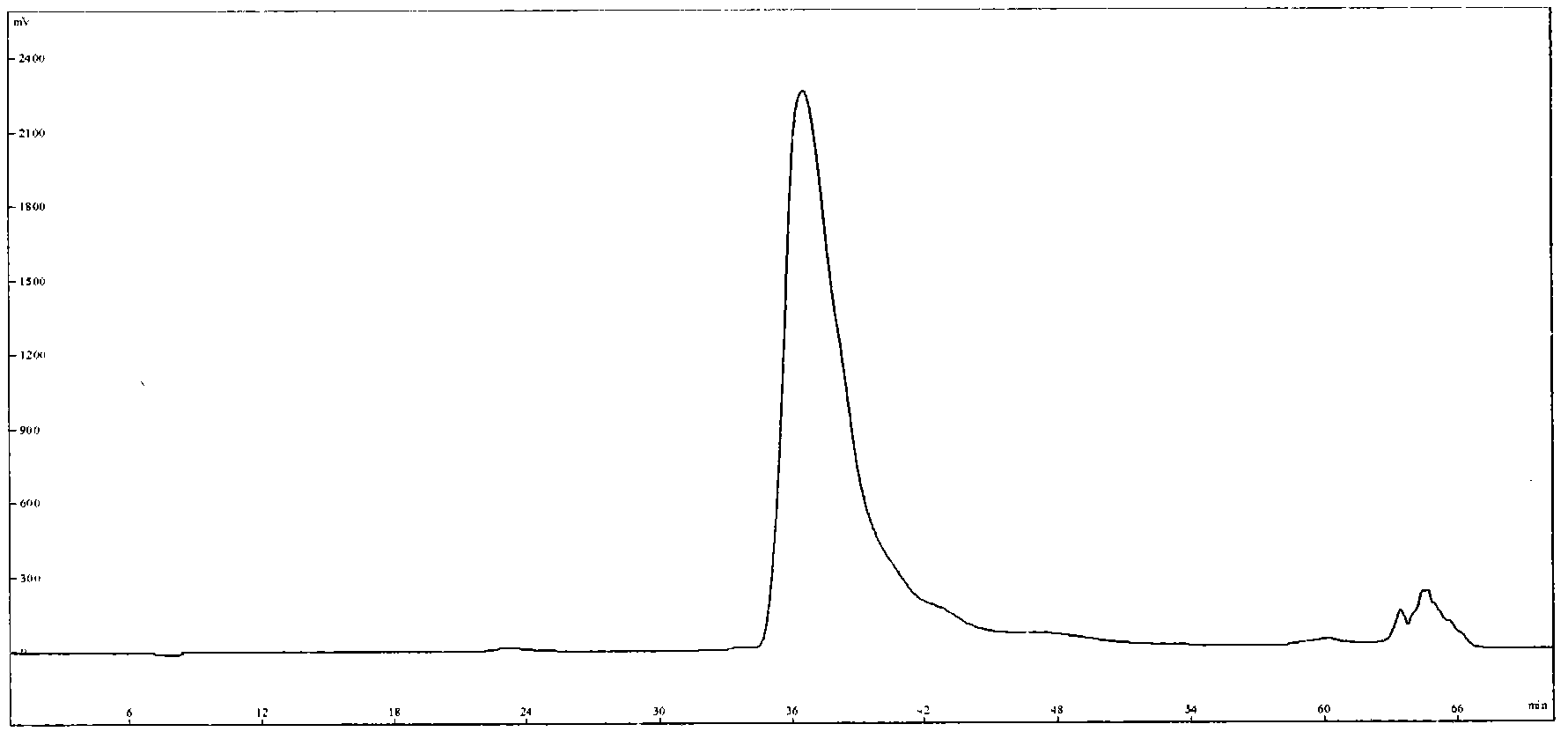

Embodiment 2

[0036] Embodiment 2: L-tryptophan separation and extraction method

[0037] (1) Take 5 kg of Nitraria seeds, grind them, add 75% ethanol, and heat extract in a decoction machine. The extraction temperature is 60° C., and the extraction time is 3 hours. A total of three extractions are performed. The first feed-to-liquid ratio is 1:12, the second feed-to-liquid ratio is 1:10, and the third feed-to-liquid ratio is 1:8. The liquid was taken and concentrated under reduced pressure to 200mL, and then extracted 5 times with petroleum ether, and the extraction ratio of petroleum ether was 200mL of crude extract and 700mL of petroleum ether.

[0038] (2) Specifications of macroporous resin column: diameter 5 cm, column height 1.2 m

[0039] Column loading: Take 1.5kg D101 macroporous adsorption resin, put it into the chromatographic column, perform desorption treatment after three days of adsorption, flush the column with water and collect samples for each column volume (column volum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com