High stability silicone emulsion and its preparation method and application

A silicone emulsion, high stability technology, applied in the direction of coating, etc., can solve the problems affecting the performance of silicone emulsion, emulsion instability, etc., to achieve the effect of ensuring human health, simple production process, and good emulsification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

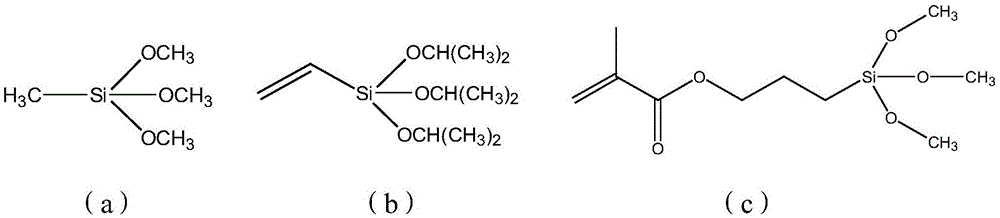

[0047] In this embodiment, a highly stable silicone emulsion includes the following raw materials in parts by weight: 10 parts of silane monomers, 0.05 parts of emulsifiers, 0.03 parts of initiators, and 89.92 parts of deionized water, wherein the silane monomers are allyl tris(trimethylsiloxy) silane;

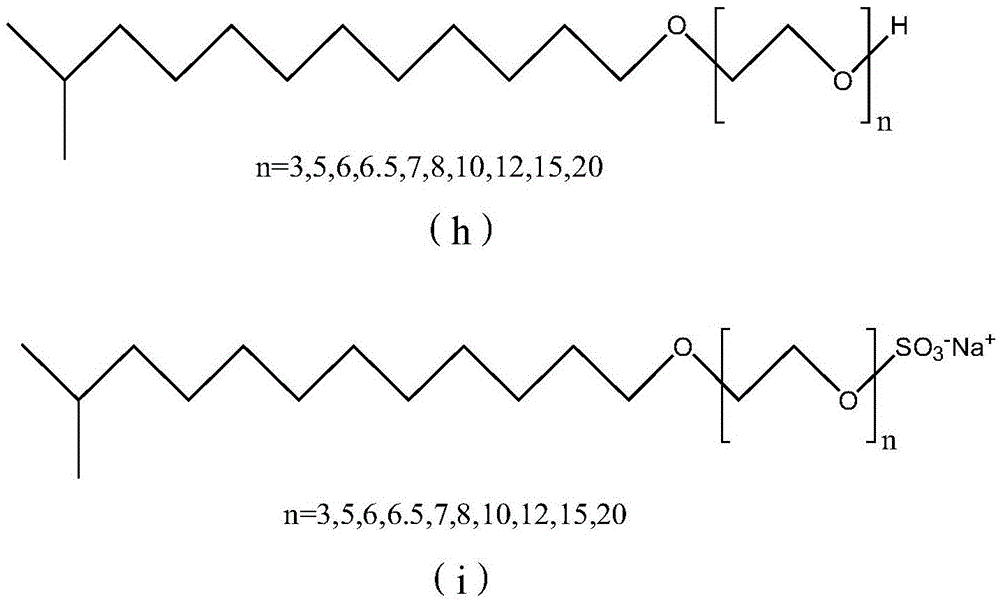

[0048] Described emulsifier is the isotridecyl polyoxyethylene ether (5) with mass ratio of 5:1: sodium lauryl sulfate;

[0049] The initiator is potassium persulfate.

[0050] The preparation method of above-mentioned organosilicon emulsion is as follows:

[0051] (1) Preparation of pre-emulsion

[0052] At room temperature, pour 89.92 parts of deionized water and 0.05 part of emulsifier into a four-necked flask in turn, stir at a high speed of 800 r / min for 10 minutes, and then add 10 parts of silane monomer to a constant pressure dropping funnel, and dropwise add it to 5 minutes. In the four-necked flask, continue to stir for 0.5h and ultrasonicate for 10min to obtain a ...

Embodiment 2

[0060] In this embodiment, a highly stable silicone emulsion includes the following raw materials by weight: 20 parts of silane monomer, 0.4 part of emulsifier, 0.16 part of initiator, and 79.44 parts of deionized water, wherein the silane monomer is γ -methacryloyloxypropyltrimethylsilane;

[0061] Described emulsifier is isotridecyl polyoxyethylene ether (5) and sodium dodecyl sulfonate in mass ratio of 1:5;

[0062] The initiator is potassium persulfate.

[0063] The preparation method of above-mentioned organosilicon emulsion is as follows:

[0064] (1) Preparation of pre-emulsion

[0065] At room temperature, pour 79.44 parts of deionized water and 0.4 part of emulsifier into a four-necked flask in turn, stir at a high speed of 800 r / min for 10 minutes, and then add 20 parts of silane monomer to a constant pressure dropping funnel, and add it dropwise to 10 minutes. In the four-necked flask, continue to stir for 0.5h and ultrasonicate for 10min to obtain a stable milky...

Embodiment 3

[0073] The high-stability silicone emulsion in this embodiment includes the following raw materials by weight: 35 parts of silane monomer, 1.05 parts of emulsifier, 0.32 parts of initiator, and 63.63 parts of deionized water, wherein the silane monomer is γ -methacryloyloxypropyltris(trimethylsiloxy)silane;

[0074] The emulsifier is isotridecanol polyoxyethylene ether (5) and isotridecanol polyoxyethylene ether (5) sodium sulfonate in a mass ratio of 1:1;

[0075] The initiator is potassium persulfate.

[0076] The preparation method of above-mentioned organosilicon emulsion is as follows:

[0077] (1) Preparation of pre-emulsion

[0078] At room temperature, pour 63.63 parts of deionized water and 1.05 parts of emulsifier into the four-necked flask in turn, stir at a high speed of 900 r / min for 10 minutes, and then add 35 parts of silane monomer to the constant pressure dropping funnel, and add dropwise to the flask within 15 minutes. In the four-necked flask, continue to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com