Method for improving plasticity and flexibility of bacterial cellulose membrane

A technology of bacterial cellulose membrane and bacterial cellulose, applied in the fields of polymer chemistry and polymers, can solve the problems of lack of flexibility and plasticity of bacterial cellulose membrane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

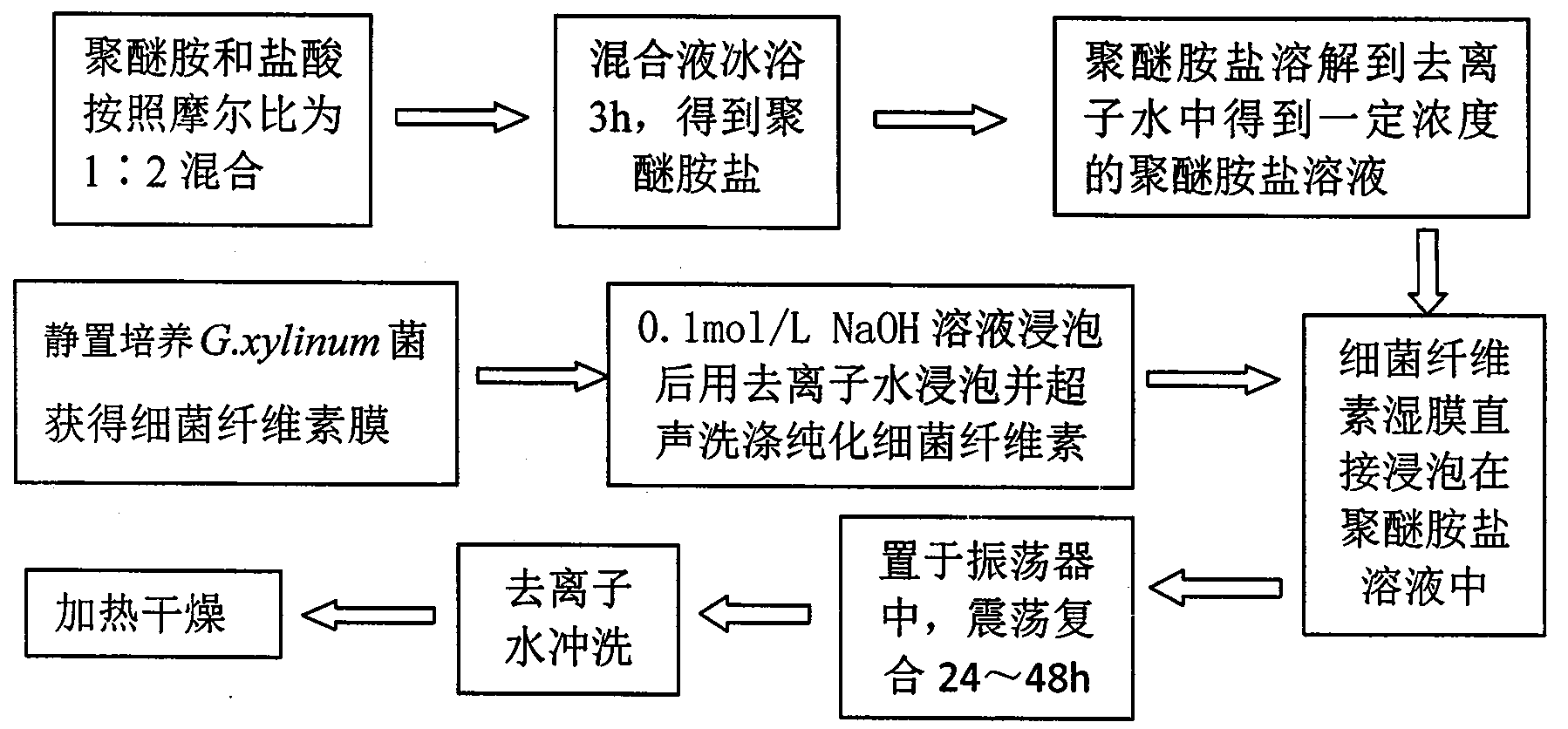

Method used

Image

Examples

Embodiment Construction

[0020] In the present invention, after the bacterial cellulose membrane is fermented, synthesized and purified, it is not dried and then combined with the wet membrane. Compared with the previous composite of the dry membrane, because the water holding rate of the bacterial cellulose membrane can reach 99%, it is suitable for The compounding of the wet film can make the toughening agent penetrate into the three-dimensional network structure of the bacterial cellulose film better and more; the invention is carried out under normal temperature and pressure, which reduces the operating cost and has less environmental pollution.

[0021] Take bacterial cellulose / polyetheramine D230 composite as an example:

[0022] 1) Preparation of cellulose membrane

[0023] Pick 1~3 rings of G.xylinum bacteria from the slope under sterile conditions and inoculate them into the Erlenmeyer flasks filled with 100mL of sterilized medium, and place them in a shaker incubator at 30°C and 180rpm Unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com