High-temperature-resistant platable polyphenylether alloy material and preparation method thereof

A technology of alloy material and polyphenylene ether, which is applied in the field of high-temperature-resistant electroplatable polyphenylene ether alloy material and its preparation, can solve the problems of unseen, high-temperature electroplating variability, dimensional instability, etc., and achieve improved temperature resistance, non-deformable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

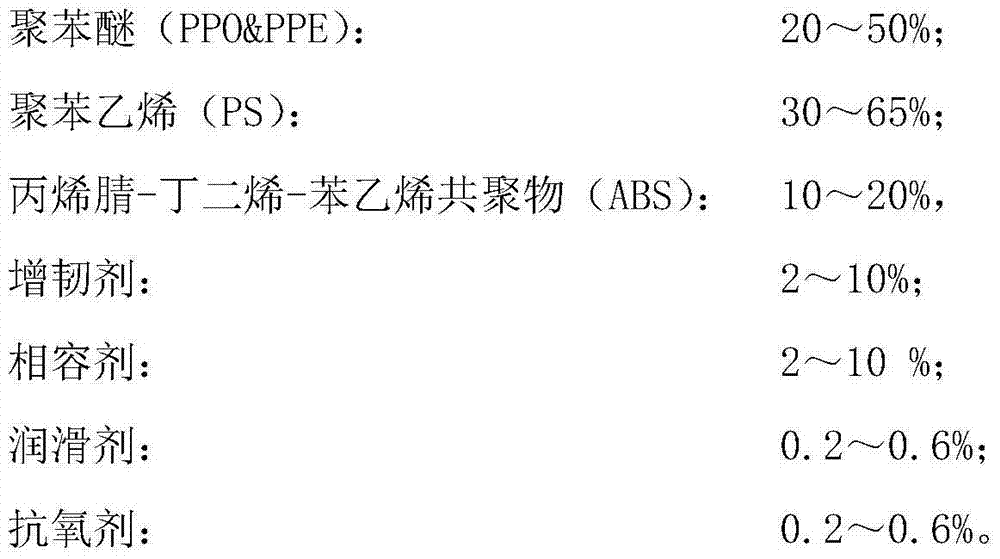

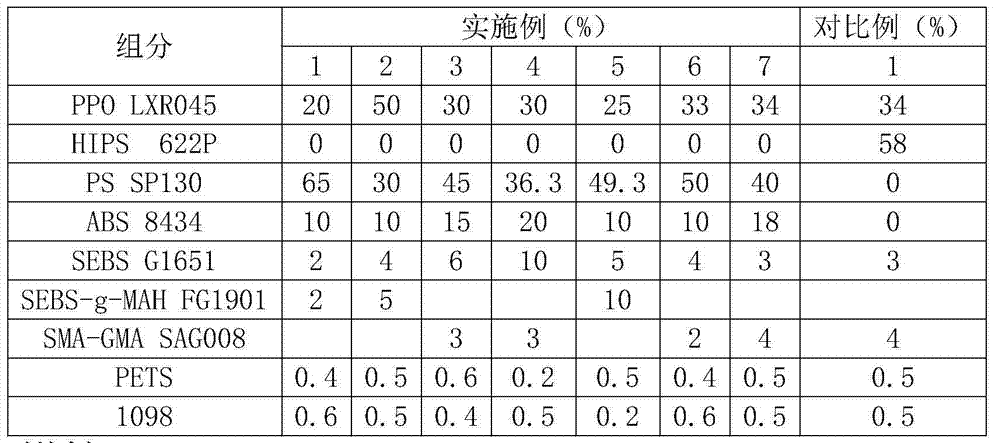

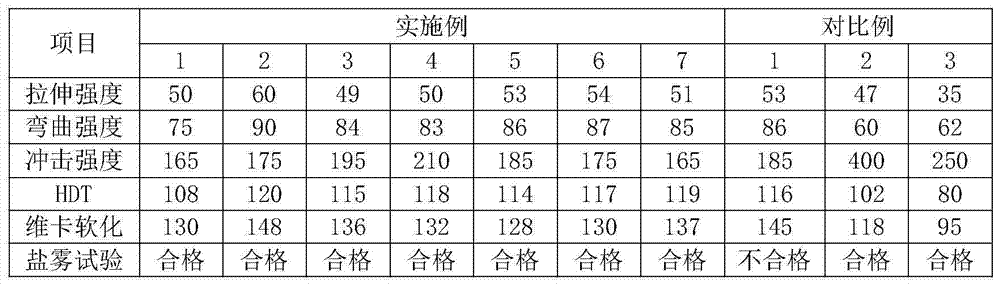

[0031] This embodiment relates to a high-temperature-resistant electroplatable polyphenylene ether alloy material, and its components and weight percentages are shown in Table 1.

[0032] The preparation of the polyphenylene ether alloy material specifically includes the following steps:

[0033] (1) Weighing by weight: PPO LXR045: 20%; PS SP130: 65%; ABS 8434: 10%; SEBSG1651: 2%; FG 1901: 2%; PETS: 0.4%; 1098: 0.6%; Put the raw materials into a high-speed mixer and mix for 3-8 minutes.

[0034] (2) Extrude the above-mentioned mixed material by a twin-screw extruder and granulate it. The rotating speed of the screw machine is 400 rpm and the temperature is 235°C.

Embodiment 2

[0036] This embodiment relates to a high-temperature-resistant electroplatable polyphenylene ether alloy material, and its components and weight percentages are shown in Table 1.

[0037] The preparation of the polyphenylene ether alloy material specifically includes the following steps:

[0038] (1) Weighing by weight: PPO LXR045: 50%; PS SP130: 30%; ABS 8434: 10%; SEBSG1651: 4%; FG 1901: 5%; PETS: 0.5%; 1098: 0.5%; The ingredients were put into a high-speed mixer and mixed for 5 minutes.

[0039] (2) Extrude and pelletize the above-mentioned mixed material by a twin-screw extruder, the rotating speed of the screw machine is 500 rpm, and the temperature is 275°C.

Embodiment 3

[0041] This embodiment relates to a high-temperature-resistant electroplatable polyphenylene ether alloy material, and its components and weight percentages are shown in Table 1.

[0042] The preparation of the polyphenylene ether alloy material specifically includes the following steps:

[0043] (1) Weighing by weight: PPO LXR045: 30%; PS SP130: 45%; ABS 8434: 15%; SEBSG1651: 6%; SAG008: 3%; PETS: 0.6%; 1098: 0.4%; the above raw materials Place in a high speed mixer and mix for 5 minutes.

[0044] (2) Extrude and pelletize the above-mentioned mixed material by a twin-screw extruder, the rotating speed of the screw machine is 600 rpm, and the temperature is 255°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com