Cadmium plating method for metal product surface treatment

A surface treatment and cadmium plating technology, which is applied in the field of surface treatment of metal products, can solve problems such as unqualified and affecting product quality, and achieve the effect of product quality assurance and adhesion enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific embodiment described in the present invention is described as follows again:

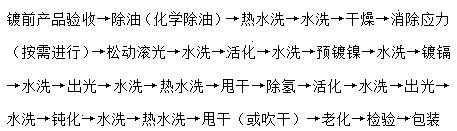

[0044] Surface treatment cadmium plating process method step of the present invention:

[0045] Qualified products are chemically degreased (according to the steps in C below); when washing with hot water for the first time, wash with hot water at 50°C to 90°C, and after the first wash, wash at 10°C to 30°C Wash in clean water; dry, dry in an oven at 40°C to 80°C; loosen and tumbling, use a vibrating tumbling machine for tumbling; the second washing, wash in clean water at 10°C to 30°C; the first time Activation, (according to the following instructions); the third washing, cleaning in clean water at 10°C to 30°C; pre-plating with nickel; the fourth washing, cleaning in clean water at 10°C to 30°C; cadmium plating; fifth Washing with water for the first time in clean water at 10°C to 30°C; the first time for light emission to remove surface oxides; washing with water for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com