TiN coating mold with better wear resistance and fatigue performance

A coating and mold technology, which is applied in the field of TiN coating molds, can solve the problems of reducing the mechanical properties of the coating, the coating quality is difficult to control, and the coating has many pores, so as to achieve easy promotion, improve the fracture mechanical properties of the coating, The effect of high fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

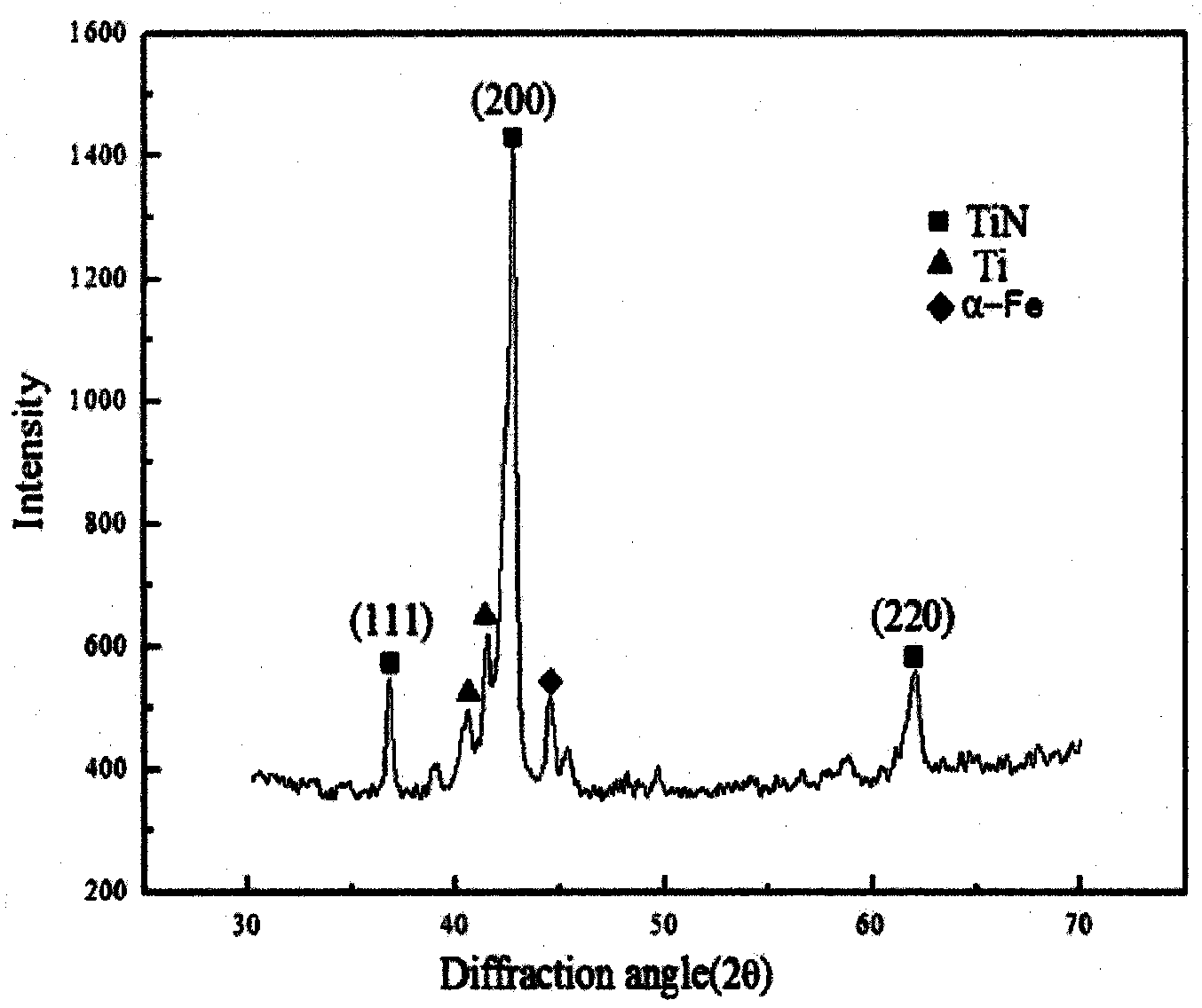

[0027] Example 1 Preparation of coating

[0028] The coating preparation process is divided into four stages: preparation of Ti powder, mold surface pretreatment, cladding, and in-situ synthesis of TiN composite coating. The four stages are as follows:

[0029] (1) Using Ti powder as raw material, the particle size of Ti powder is 80-100μm.

[0030] Using Ti powder as the raw material, the powder is sieved, and the sieve is 125 mesh-300 meshes to obtain a relatively uniform Ti powder with better fluidity and a particle size of 80-100 microns.

[0031] (2) Pretreatment of mold surface.

[0032] (2-1) Grind the mold surface first to make the surface roughness of the mold reach Ra=0.8μm;

[0033] (2-2) Then clean the surface of the mold with alcohol or acetone to remove oil stains on the surface of the mold;

[0034] (3) Perform cladding.

[0035] (3-1) The cladding equipment adopts the PAW-1 plasma cladding platform, the cladding parameters are: current 80A, voltage 220V, powder feeding rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com