Acetone gas sensor based on alpha-Fe2O3/SnO2 composite nano fibers and preparation method thereof

A technology of composite nanofibers and gas sensors, applied in fiber processing, filament/thread forming, textiles and papermaking, etc., can solve the problems of fast response and recovery speed, high sensitivity of difficult acetone sensors, etc., to achieve increased sensitivity and fast adsorption The effect of desorption and recovery speed acceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

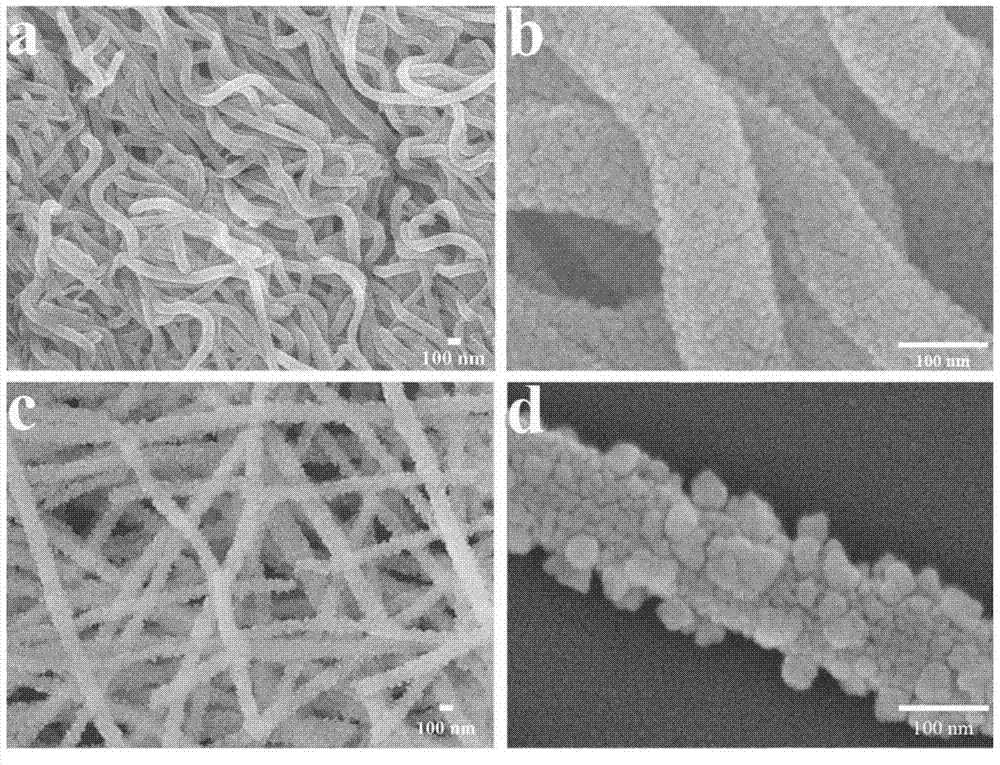

Embodiment 1

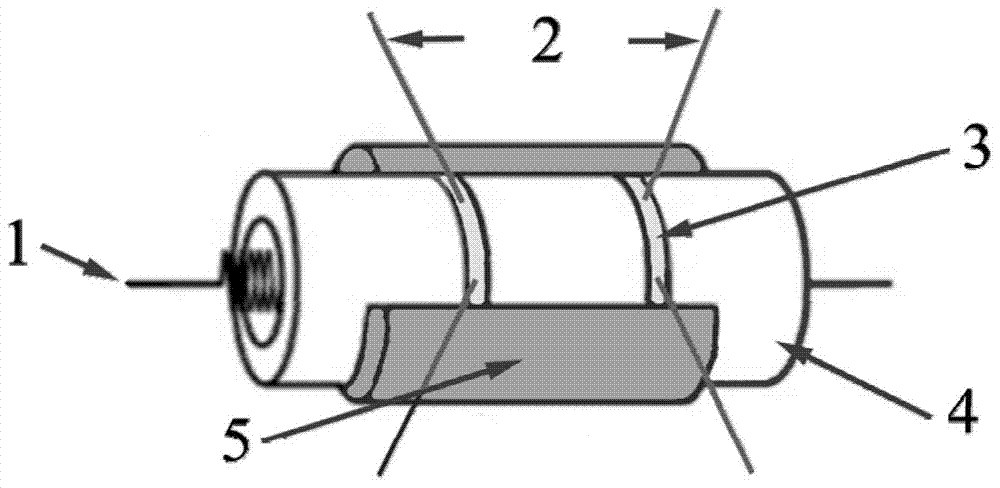

[0044] α-Fe composited with Fe:Sn molar ratio of 1:2 2 o 3 / SnO 2 Nanofibers are used as gas-sensitive materials to make FSO-1 type acetone sensors. The manufacturing process is as follows:

[0045] (1) Weigh 0.4g SnCl 4 ·5H 2 O, 1g of polyacrylonitrile (molecular weight 15w), put it into beaker 1, add 10mL of dimethylformamide organic solvent, and stir for 1h in a water bath at 70°C to obtain a uniform mixed solution. Weigh 0.15g FeCl 3 ·6H 2 O, 1g polyvinylpyrrolidone (molecular weight 130w), put it into beaker 2, add 10mL dimethylformamide organic solvent, stir at room temperature for 1h to obtain a uniform mixed solution. The solutions in beaker 1 and beaker 2 were mixed together, and stirred at 70° C. for 3 hours to obtain a precursor solution.

[0046] (2) Transfer the precursor solution obtained in (1) above into a 20mL syringe, and use a metal needle with an inner diameter of 0.7mm at the top of the syringe. Using electrospinning technology, the specific parame...

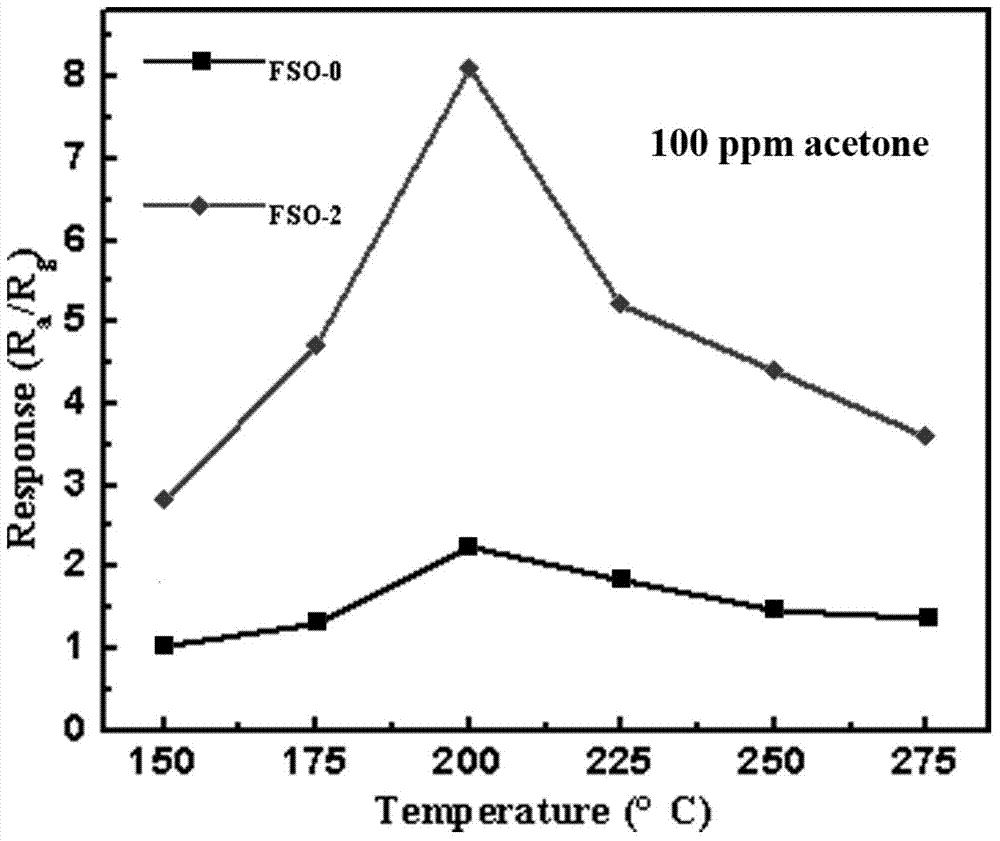

Embodiment 2

[0053] α-Fe composited with Fe:Sn molar ratio of 1:1 2 o 3 / SnO 2 Nanofibers are used as gas-sensitive materials to make FSO-2 acetone sensors. The manufacturing process is as follows:

[0054] (1) Weigh 0.4g SnCl 4 ·5H 2 O, 1g of polyacrylonitrile (molecular weight 15w), put it into beaker 1, add 10mL of dimethylformamide organic solvent, and stir for 1h in a water bath at 70°C to obtain a uniform mixed solution. Weigh 0.3g FeCl 3 ·6H 2 O, 1g polyvinylpyrrolidone (molecular weight 130w), put it into beaker 2, add 10mL dimethylformamide organic solvent, stir at room temperature for 1h to obtain a uniform mixed solution. The solutions in beaker 1 and beaker 2 were mixed together, and stirred at 70° C. for 3 hours to obtain a precursor solution.

[0055] (2) Transfer the precursor solution obtained in (1) above into a 20mL syringe, and use a metal needle with an inner diameter of 0.7mm at the top of the syringe. Using electrospinning technology, the specific parameters a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com