Metal antenna structure for improving slow axis far field of surface emission semiconductor laser unit

An antenna structure and laser technology, applied in optics, instruments, optical components, etc., can solve the problems of unsuitable mass production, difficult process, high price, etc. High precision engraving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

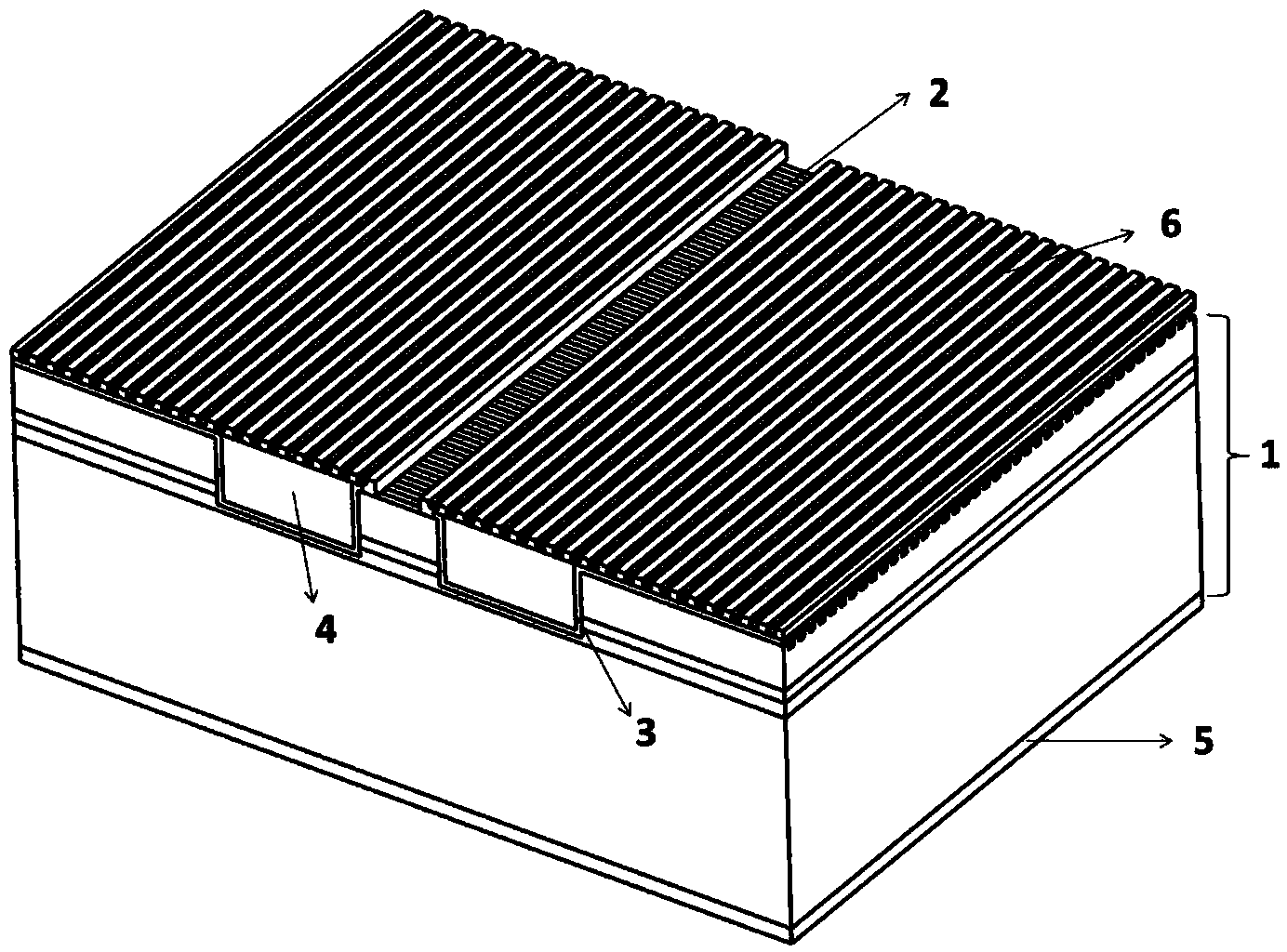

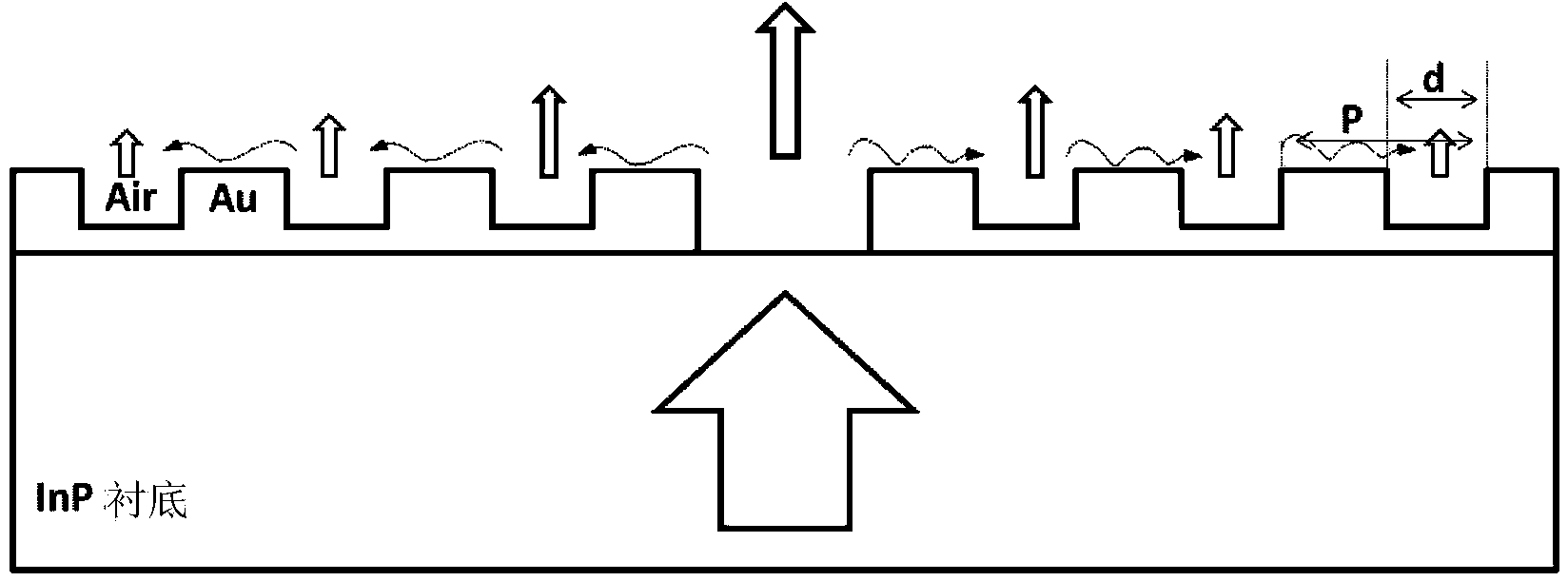

[0025] The invention provides a metal antenna structure for improving the slow axis far field of a surface-emitting semiconductor laser, figure 1 A three-dimensional structure schematic diagram of a metal antenna for improving the slow-axis far field of a surface-emitting semiconductor laser according to an embodiment of the present invention is given. Such as figure 1 As shown, the antenna includes: a substrate 1, a grating layer 2, an electrical isolation layer 3, a double groove filling 4, a lower ohmic contact layer 5, and a subwavelength metal plasma antenna 6, wherein:

[0026] A double-channel ridge waveguide structure is fabricated on the substrate 1, and the ridge area of the double-channel ridge waveguide str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com