Aircraft Model Assembly Method Oriented to Lean Production

A technology of aircraft model and assembly method, which is applied in 3D modeling, program control device, image data processing, etc., can solve the problems of low assembly efficiency of aircraft model, waste of material movement, disorder, etc., and achieve the path of material handling and movement Fast and convenient, clear information transmission, and orderly storage and retrieval

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

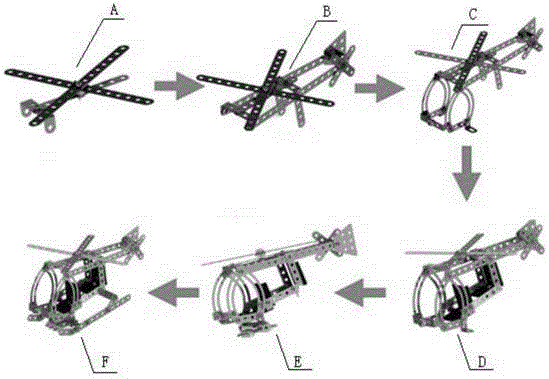

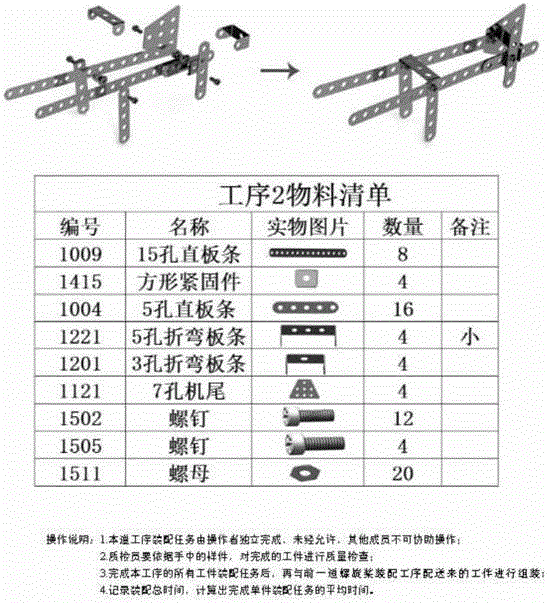

[0026] The aircraft model assembly method oriented to lean production in this embodiment, lean production (Lean Production), referred to as "lean", is a management philosophy derived from the Toyota Production System. Including many well-known manufacturing companies and professors from Massachusetts Institute of Technology, the research, application and development of Toyota production methods on a global scale has promoted the emergence of lean production theory and production management system, which is still evolving and developing. From Kaizen, which focused on the production site in the past, to inventory control, production planning management, process improvement (process reengineering), cost management, employee literacy development, supply chain collaborative optimization, product life cycle management (product concept design, product development, production line design) , workbench design, operation method design and improvement), quality management, equipment resour...

specific Embodiment approach 2

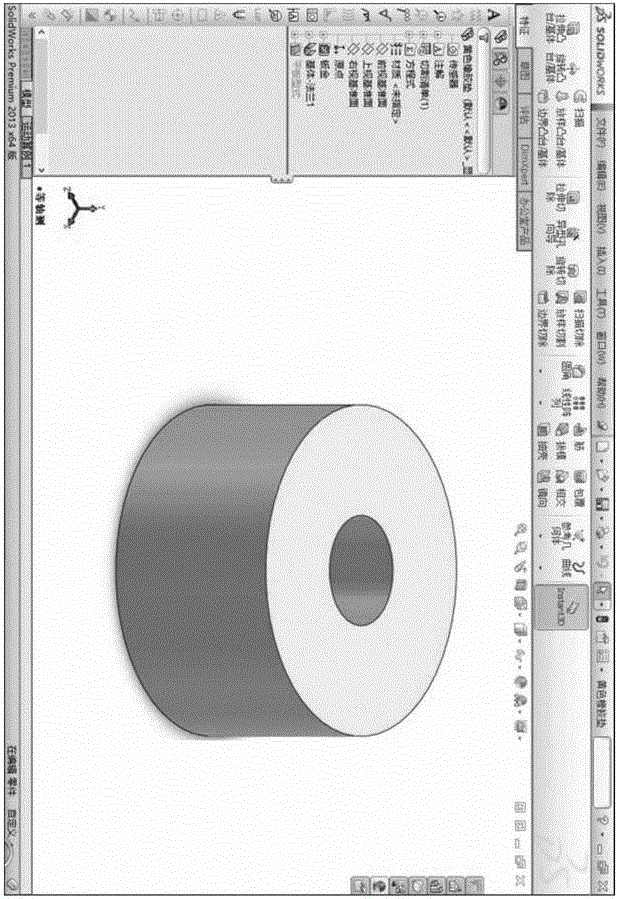

[0038] Different from the specific embodiment 1, the aircraft model assembly method oriented to lean production in this embodiment, the three-dimensional simulation process of the aircraft model described in step 1 is specifically:

[0039] Step 11: Measure the specific size of the aircraft model parts with a vernier caliper;

[0040] Step 1 and 2: Carry out 3D simulation of the aircraft model parts on the Solidworks simulation software interface according to the measured dimensions, and render according to the actual material of the aircraft model parts after determining the actual viewing angle;

[0041] Step 1 and 3: Use the 4-digit coding principle to code the 3D simulation drawing of each aircraft model part, for example, the code of the yellow rubber pad is 1402.

specific Embodiment approach 3

[0043] The difference from the specific embodiment 1 or 2 is that in the aircraft model assembly method oriented to lean production in this embodiment, the balancing method described in step 5 is: find out the sub-assembly process with the minimum man-hour adjacent to the bottleneck process, and Calculate and average the man-hours of the identified bottleneck processes, then decompose the bottleneck process into processes, assign the assembly process with more than the average man-hours to the sub-assembly process with the smallest man-hours, and complete the balanced production process of the general assembly path. After balancing, each sub-assembly process The effect of the man-hour trend of the assembly process is as follows: Figure 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com