A kind of zinc ion rechargeable battery and its manufacturing method

A rechargeable battery, zinc ion technology, applied in electrode manufacturing, sustainable manufacturing/processing, secondary batteries, etc., can solve the problems of low utilization rate of active materials, uneven battery capacity, large current attenuation, etc., to improve high current characteristics, the effect of improving capacity and energy density, and improving cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

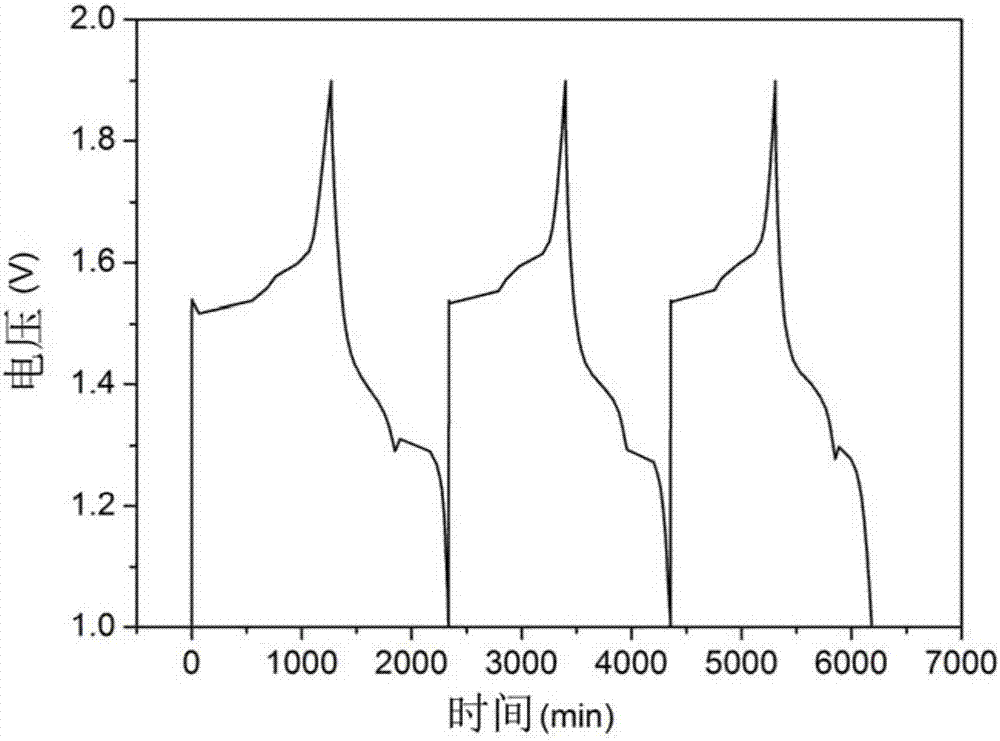

Embodiment 1

[0042] Graphene-loaded manganese dioxide preparation method is as follows: add 0.4 gram of graphene to 300 milliliters (mL) 0.1 moles per liter (mol L -1 ) in the manganese acetate aqueous solution, so that the graphene is evenly dispersed, and then 200mL0.1M L -1 The potassium permanganate aqueous solution is added in the manganese acetate solution, and stirred for 10 hours, so that the manganese dioxide is fully deposited and attached to the surface of the graphene, then the precipitate is filtered, washed with deionized water, and dried to obtain the graphene-loaded manganese oxide.

[0043] Graphene-loaded manganese dioxide powder, conductive agent carbon black and binder polyvinylidene fluoride are mixed in a mass ratio of 8:1:1 and coated on stainless steel foil, cut into a certain size, and placed in a vacuum Dry it into a graphene-loaded manganese dioxide electrode sheet. The prepared graphene-loaded manganese dioxide electrode sheet is used as the positive electrode...

Embodiment 2

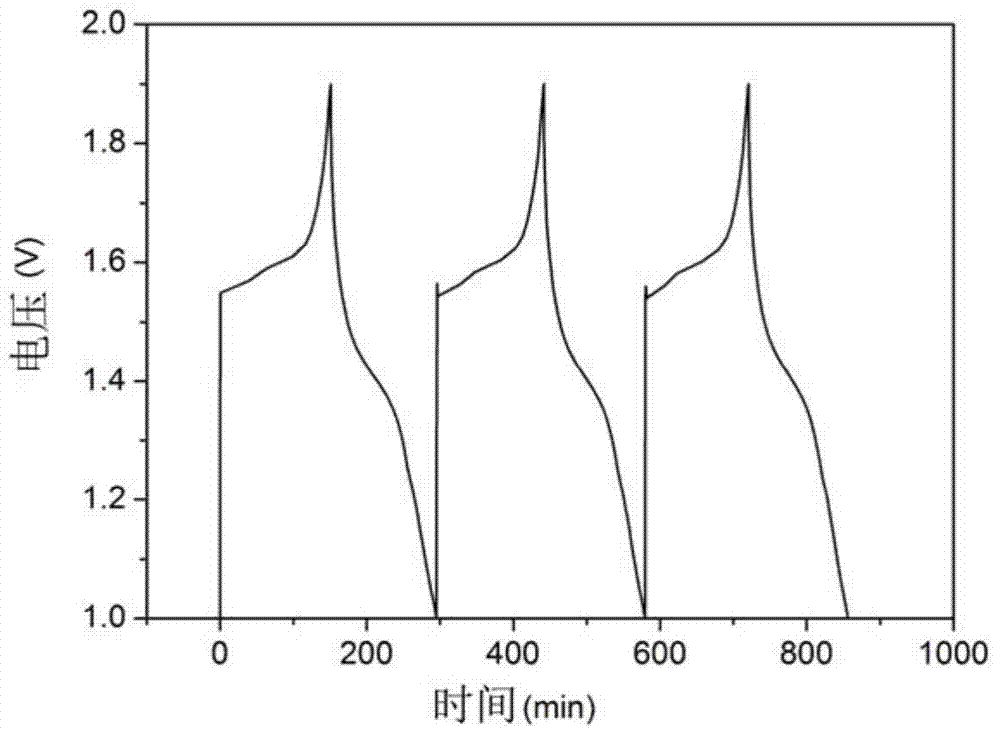

[0045] In order to illustrate the synergistic effect of the carbon-supported manganese dioxide composite material and manganese ions in the electrolyte, the present invention assembled two other batteries to compare the effect of the synergistic effect on increasing the battery capacity. At first the present invention has prepared manganese dioxide powder according to the following method, put 200mL0.1M L -1 Add 300 milliliters (mL) of 0.1 moles per liter (mol L -1 ) in the manganese acetate aqueous solution, fully stirred for 10 hours, then filtered the precipitate, washed with deionized water, and dried to obtain the manganese dioxide powder. Mix manganese dioxide powder, conductive agent carbon black, and binder polyvinylidene fluoride in a mass ratio of 7:2:1, then coat it on stainless steel foil, cut it into a certain size, and dry it in a vacuum. Manganese dioxide electrodes. The manganese dioxide electrode sheet is used as the positive electrode, the 0.1mm thick zinc ...

Embodiment 3

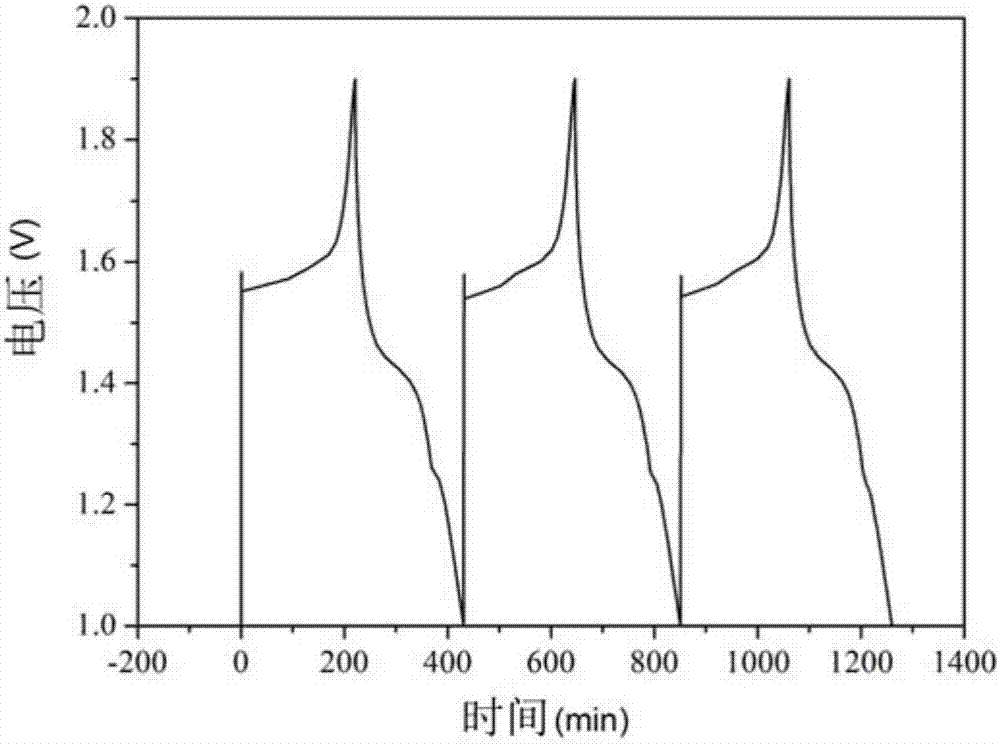

[0048] The preparation method of carbon nanotube-loaded manganese dioxide is as follows: 0.6 gram of carbon nanotubes is added to 300 milliliters (mL) of 0.1 moles per liter (mol L -1 ) in the manganese acetate aqueous solution, so that the carbon nanotubes can be dispersed evenly, and then 200mL0.1ML -1 The potassium permanganate aqueous solution was added to the manganese acetate solution, and stirred for 10 hours, so that the manganese dioxide was fully deposited and attached to the surface of the carbon nanotubes, then the precipitate was filtered, washed with deionized water, and dried to obtain the carbon nanotubes loaded with manganese dioxide.

[0049] Mix carbon nanotube-loaded manganese dioxide powder, conductive agent carbon black, and binder polyvinylidene fluoride in a mass ratio of 8:1:1, then coat it on stainless steel foil, cut it into a certain size, and place it in a vacuum Dry in medium to make carbon nanotube-loaded manganese dioxide electrode sheet. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com