Zinc oxide pressure-sensitive resistor raw material

A varistor, zinc oxide technology, applied in varistors, varistor cores, overvoltage protection resistors, etc., can solve the problems of varistor electrical decline, antimony compounds reduce libido, damage the heart, etc. , to achieve the effect of reducing the limiting voltage ratio, improving the high current characteristics, and improving the nonlinearity of the ceramic body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

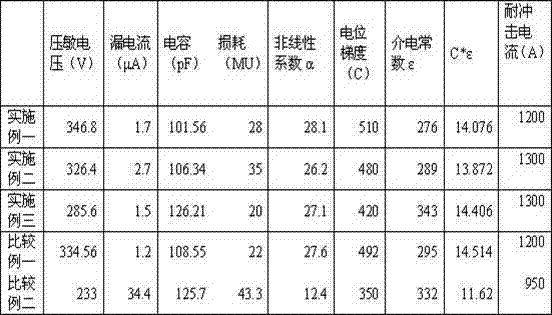

Examples

Embodiment 1

[0030] Zinc oxide varistor raw materials, containing the following components: ZnO 96.48%, Bi 2 o 3 0.7%, Cr 2 o 3 0.6%, Nb 2 o 5 0.5%, MnCO 3 0.5%, Co 2 o 3 1%, Ni 2 o 3 0.1%, SiO 2 0.1%, Al 2 (NO 3 ) 3 9H 2 O 0.015%.

[0031] Weigh the above components except zinc oxide (the mixture thereof is hereinafter referred to as additive powder), use a polyethylene tank as a ball mill tank, use zirconia balls and deionized water as a ball milling medium, zirconia balls, additive powder, deionized water The mass ratio of water is 80:1:12, wet grinding in the planetary ball mill for 5~12h (12h in this example), and the speed is 300-500rmp (350rmp in this example).

[0032] Then add zinc oxide powder corresponding to the ratio and polyvinyl alcohol (PVA) accounting for 1-3% of the total weight of the raw meal powder (used in the form of an aqueous solution, adding 2% of PVA in this example, granulation is more convenient, Tablet pressing effect is better), continu...

Embodiment 2

[0035] Zinc oxide varistor raw materials, containing the following components: ZnO 96.3%, Bi 2 o 3 0.8%, Cr 2 o 3 0.6%, MnCO 3 0.6%, Co 2 o 3 1.05%, Ni 2 o 3 0.15%, Nb 2 o 5 0.5%, Al 2 (NO 3 ) 3 9H 2 O0.02%.

[0036] Weigh the above components except zinc oxide (the mixture thereof is hereinafter referred to as additive powder), use a polyethylene tank as a ball mill tank, use zirconia balls and deionized water as a ball milling medium, zirconia balls, additive powder, deionized water The mass ratio of water is 80:1:12, wet grinding in the planetary ball mill for 5~12h (12h in this example), and the speed is 300-500rmp (350rmp in this example).

[0037] Then add the corresponding proportion of zinc oxide powder and PVA (used in the form of aqueous solution) accounting for 2% of the total weight of the raw meal powder, and continue to mix and grind in the planetary ball mill for 24 hours at a speed of 350rmp. After the mixing is completed, pour The porcelai...

Embodiment 3

[0040] Zinc oxide varistor raw materials, containing the following components: ZnO 95.5%, Bi 2 o 3 1.2%, Cr 2 o 3 0.7%, MnCO 3 0.7%, Co 3 o 4 1%, Ni 2 o 3 0.3%, Nb 2 o 5 0.6%, Al 2 (NO 3 ) 3 9H 2 O 0.02%.

[0041] Weigh the above components except zinc oxide (the mixture thereof is hereinafter referred to as additive powder), use a polyethylene tank as a ball mill jar, use zirconia balls and deionized water as a ball milling medium, zirconia balls, additive powder, deionized water The mass ratio of water is 80:1:12, wet grinding in the planetary ball mill for 5~12h (12h in this example), and the speed is 300-500rmp (350rmp in this example).

[0042] Then add the corresponding proportion of zinc oxide powder and PVA (used in the form of aqueous solution) accounting for 2% of the total weight of the raw meal powder, and continue to mix and grind in the planetary ball mill for 24 hours at a speed of 350rmp. After the mixing is completed, pour The porcelain pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com