Nickel-based rechargeable battery and manufacturing method thereof

A technology for rechargeable batteries and manufacturing methods, applied in the direction of sustainable manufacturing/processing, secondary batteries, and final product manufacturing, which can solve problems such as low capacity, achieve high capacity, increase capacity, and improve high-current characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

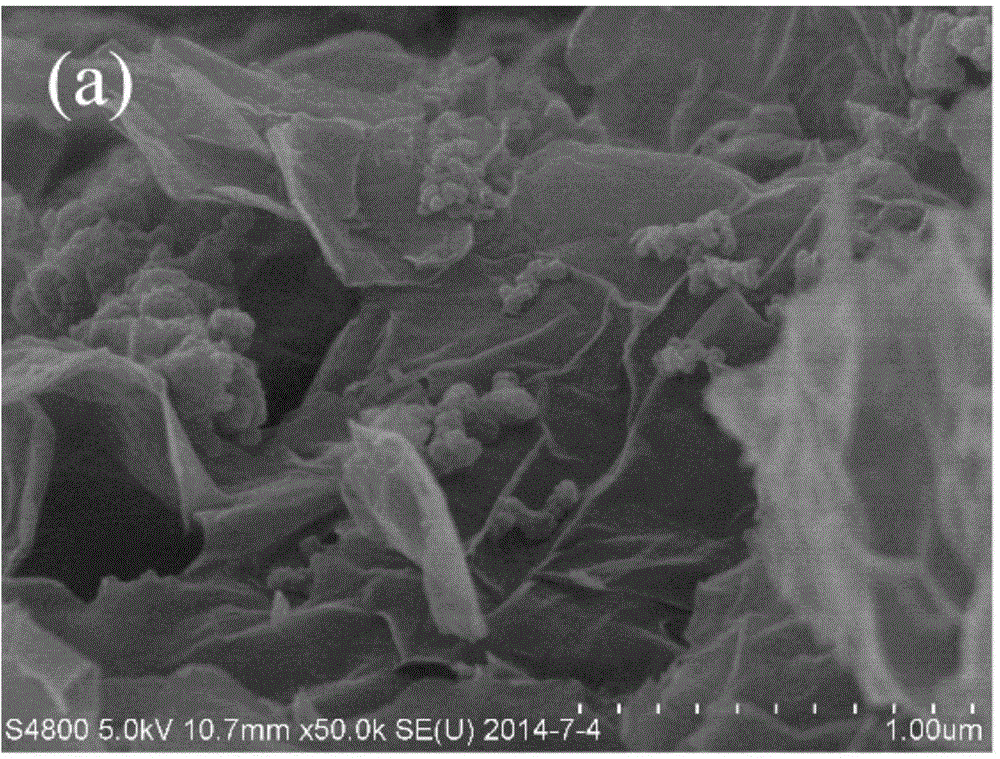

[0043] The preparation method of graphene-supported manganese dioxide is as follows: 0.4 grams of graphene is added into 300 mL of manganese acetate aqueous solution with a concentration of 0.1 mol / L and fully stirred to allow the graphene to disperse evenly. Then add 200mL of potassium permanganate aqueous solution with a concentration of 0.1M / L into the manganese acetate solution, and stir for 10 hours, so that manganese dioxide is fully deposited on the surface of graphene, then filter the precipitate, and wash with deionized water and drying to obtain graphene-loaded manganese dioxide powder, that is, carbon-manganese dioxide composite material.

[0044] Graphene-loaded manganese dioxide powder, conductive agent carbon black and binder polyvinylidene fluoride are mixed in a mass ratio of 8:1:1 and coated on stainless steel foil, cut into a certain size, and placed in a vacuum Dry it into a graphene-loaded manganese dioxide electrode sheet.

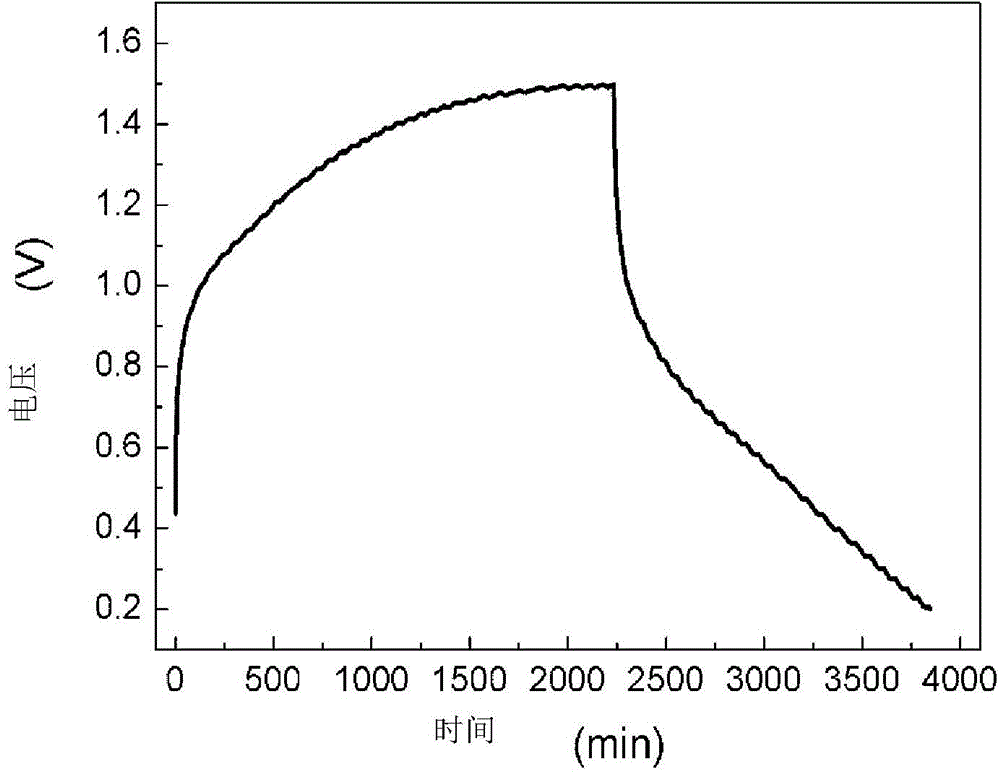

[0045] The prepared graphene-l...

Embodiment 2

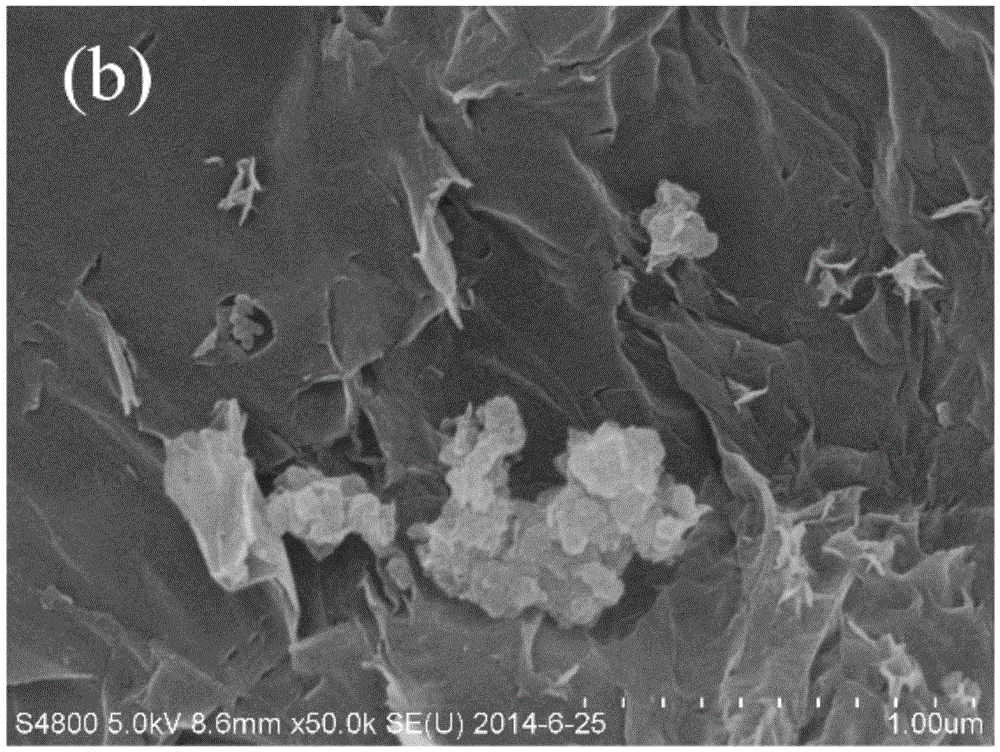

[0049] The carbon nanotube powder and the manganese dioxide powder are mixed according to the weight ratio of 2:8 to prepare the mixed powder of the carbon nanotube and the manganese dioxide, that is, the carbon-manganese dioxide composite material. The mixed powder of carbon nanotubes and manganese dioxide, the conductive agent carbon black and the binder polyvinylidene fluoride are mixed according to the mass ratio of 8:1:1, and then coated on the stainless steel foil, cut into a certain size, Dry in vacuum to form carbon nanotube-loaded manganese dioxide electrode sheets. The prepared carbon nanotube-loaded manganese dioxide electrode sheet is used as the positive electrode, the 0.1mm thick nickel foil is used as the negative electrode, and the electrolyte is NiSO with a concentration of 1mol / L. 4 Add MnSO at a concentration of 1mol / L 4 Aqueous solution, the above-mentioned positive electrode, negative electrode and electrolyte are assembled into a battery, denoted as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com