Recovery system suitable for livestock manure compost volatilized ammonia nitrogen and process thereof

A technology of livestock and poultry manure and recycling system, applied in the preparation, application, organic fertilizer and other directions of organic fertilizer, can solve the problems of secondary pollution, complicated operation, reduce ammonia gas, etc., achieve convenient maintenance, simple operation, and improve recycling efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the embodiments of the accompanying drawings.

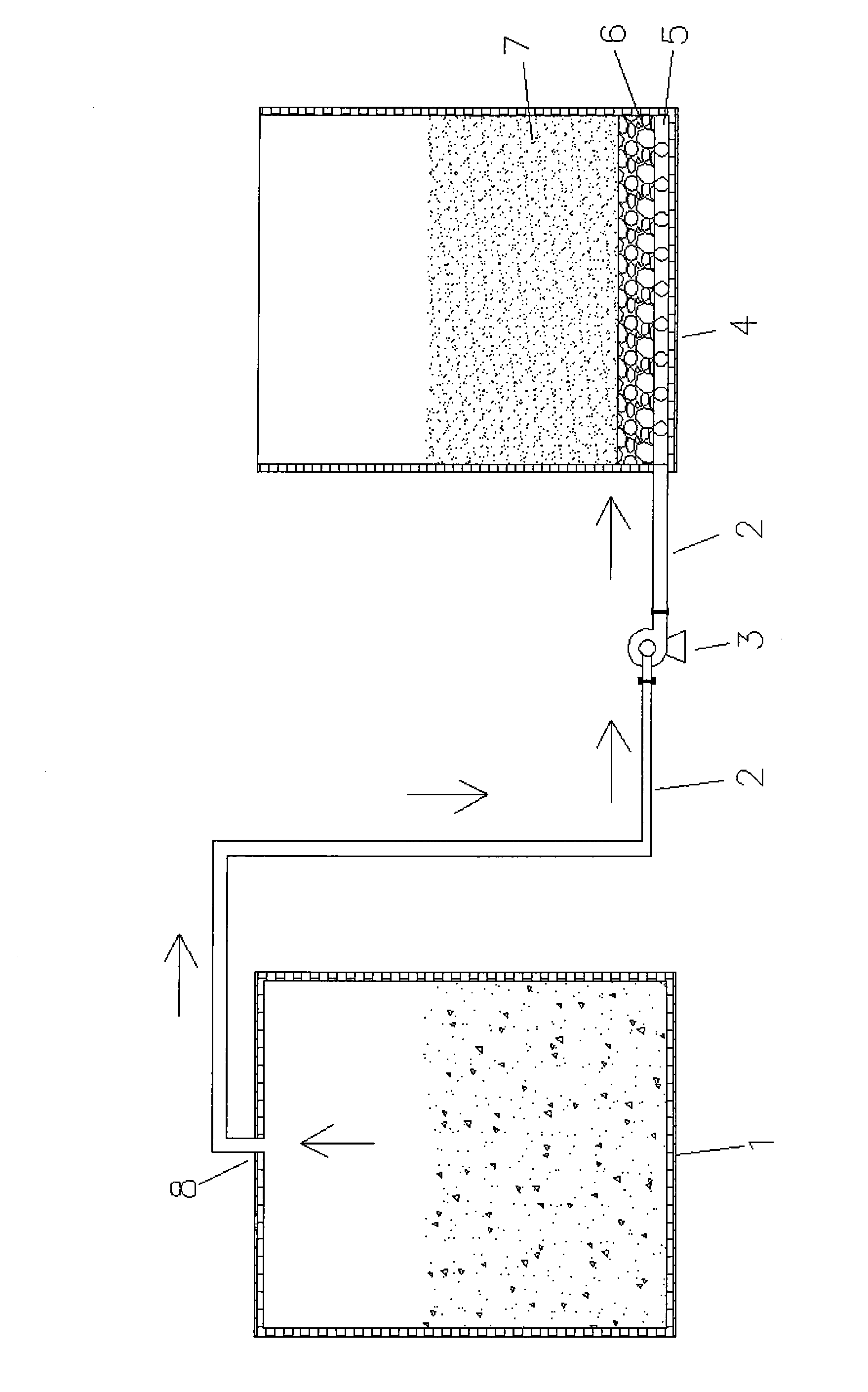

[0014] As shown in Figure 1, the recovery system and process suitable for composting volatile ammonia nitrogen from livestock and poultry manure consist of a compost fermentation bin (1), a gas delivery pipeline (2), a centrifugal fan (3) and an ammonia gas absorption bin (4). The ammonia gas absorption bin (4) includes a gas distribution system (5), padding (6) and absorbent material (7).

[0015] The compost fermentation bin (1) has a gas outlet (8), and the outlet (8) is arranged on the top, and is closely connected with the gas delivery pipeline (2), so as to ensure that the gas in the fermentation bin (1) can be completely absorbed The centrifugal fan (3) is extracted.

[0016] The gas conveying pipeline (2) is made of PVC or PPR material, which has certain anti-ammonia corrosion performance, and heat-insulating material is used for heat preser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com