Method for preparing synthetic peptide antigen 2700 of swine O-type foot and mouth disease through solid-phase fragment process

A technology for foot-and-mouth disease and synthetic peptides, which is applied in peptide preparation methods, biochemical equipment and methods, chemical instruments and methods, etc., and can solve problems such as wrong sequences, unreachable yields, and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

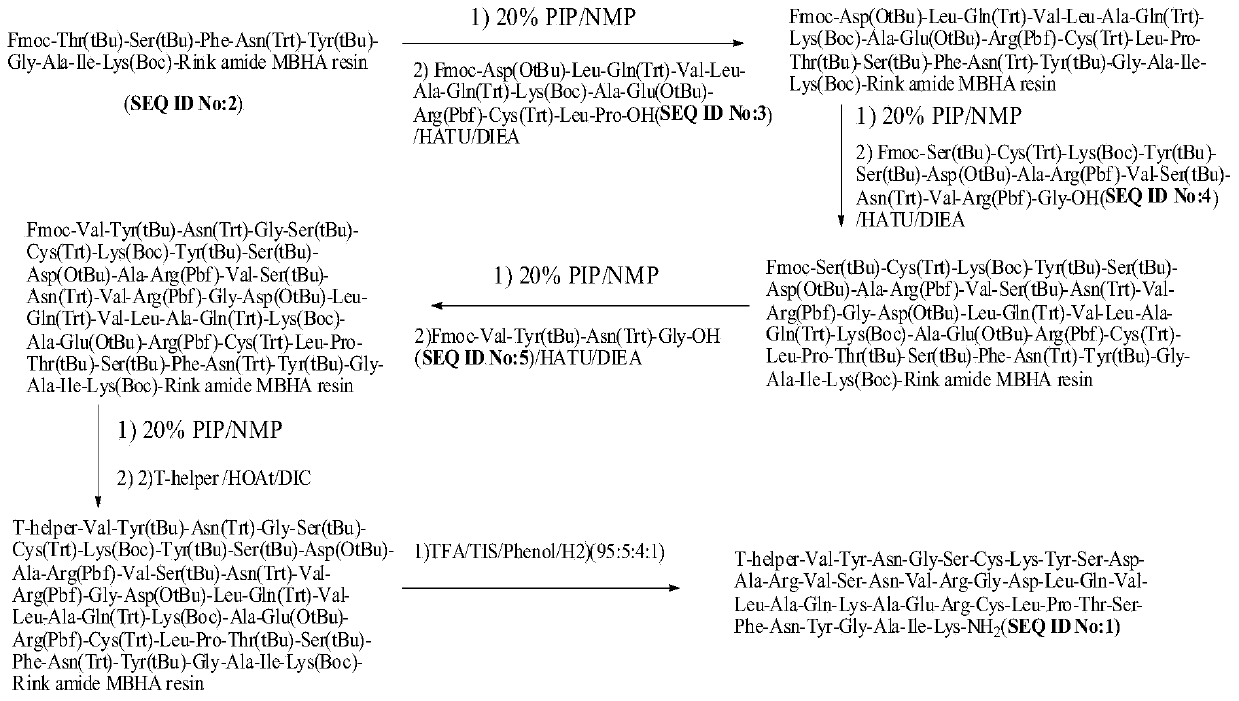

Method used

Image

Examples

Embodiment 1

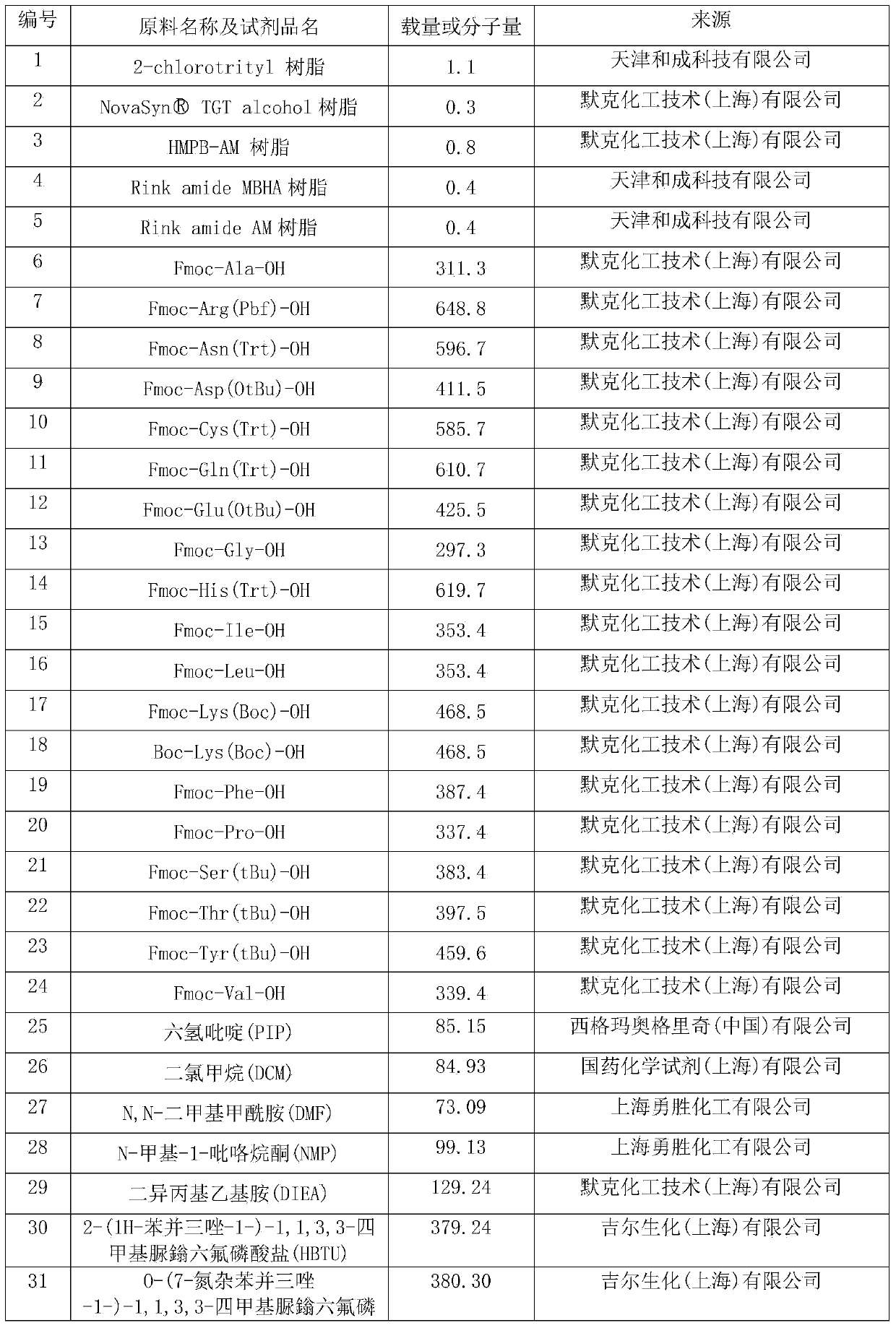

[0068] This embodiment relates to the preparation of SEQ ID No: 3 modified by 9-fluorenylmethoxycarbonyl at the amino end, comprising the following steps:

[0069] (1) Preparation of Fmoc-Pro-2-chlororityl resin

[0070] Weigh 100g of 2-chlororityl resin (100-200 mesh, 1.1mmol / g, 110mmol) into the EST-50 polypeptide synthesizer, swell with 1L of DCM for 30min, filter to dryness, add 1L to dissolve 37.1g of Fmoc-Pro- OH (110mmol, 1.0eq) and 14.2g of DIEA (18.7ml, 110mmol) in DCM were reacted at 20-25°C for 60min. After filtering to dryness, add 1L of MeOH / DIEA (9:1) solution to carry out blocking reaction for 30min. After filtering, the resin was washed several times with NMP, MeOH, and NMP in turn, and then drained to obtain Fmoc-Pro-2-chlorotrityl resin. Take a small amount of resin and wash it several times with MeOH to measure the loading by removing Fmoc method, and the measured loading is 0.70mmol / g.

[0071] (2) Preparation of Fmoc-Leu-Pro-2-chlorotrityl resin

[0072...

Embodiment 2

[0078] This embodiment relates to the preparation of SEQ ID No: 4 modified by 9-fluorenylmethoxycarbonyl at the amino end, comprising the following steps:

[0079] (1) Preparation of Fmoc-Gly-2-chlororityl resin

[0080] Weigh 100g of 2-chlororityl resin (100-200 mesh, 1.1mmol / g, 110mmol) into the EST-50 peptide synthesizer, swell with 1L of DCM for 30min, filter to dryness, add 1L to dissolve 32.7g of Fmoc-Gly- OH (110mmol) and 14.2g of DIEA (18.7ml, 110mmol) in DCM were reacted at 20-25°C for 60min. After filtering to dryness, add 1L of MeOH / DIEA (9:1) solution for capping reaction for 30min. After filtering, the resin was washed several times with NMP, MeOH, and NMP in sequence, and then drained to obtain Fmoc-Gly-2-chlorotrityl resin. Take a small amount of resin and wash it several times with MeOH to measure the loading by removing Fmoc method, and the measured loading is 0.65mmol / g.

[0081] (2) Preparation of Fmoc-Arg(Pbf)-Gly-2-chlorotrityl resin

[0082] Add 1L of ...

Embodiment 3

[0088] This embodiment relates to the preparation of SEQ ID No: 5 modified by 9-fluorenylmethoxycarbonyl at the amino end, comprising the following steps:

[0089] (1) Preparation of Fmoc-Gly-2-chlororityl resin

[0090] Weigh 100g of 2-chlororityl resin (100-200 mesh, 1.1mmol / g, 110mmol) into the EST-50 polypeptide synthesizer, swell with 1L of DCM for 30min, filter to dryness, add 1L to dissolve 49.1g of Fmoc-Gly- OH (165mmol) and 14.2g of DIEA (21.3ml, 165mmol) in DCM were reacted at 20-25°C for 60min. After filtering to dryness, add 1L of MeOH / DIEA (9:1) solution for capping reaction for 30min. After filtering, the resin was washed several times with NMP, MeOH, and NMP in sequence, and then drained to obtain Fmoc-Gly-2-chlorotrityl resin. Take a small amount of resin and wash it several times with MeOH to measure the loading by removing Fmoc method, and the measured loading is 0.80mmol / g.

[0091] (2) Preparation of Fmoc-Asn(Trt)-Gly-2-chlorotrityl resin

[0092] Add 1L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com